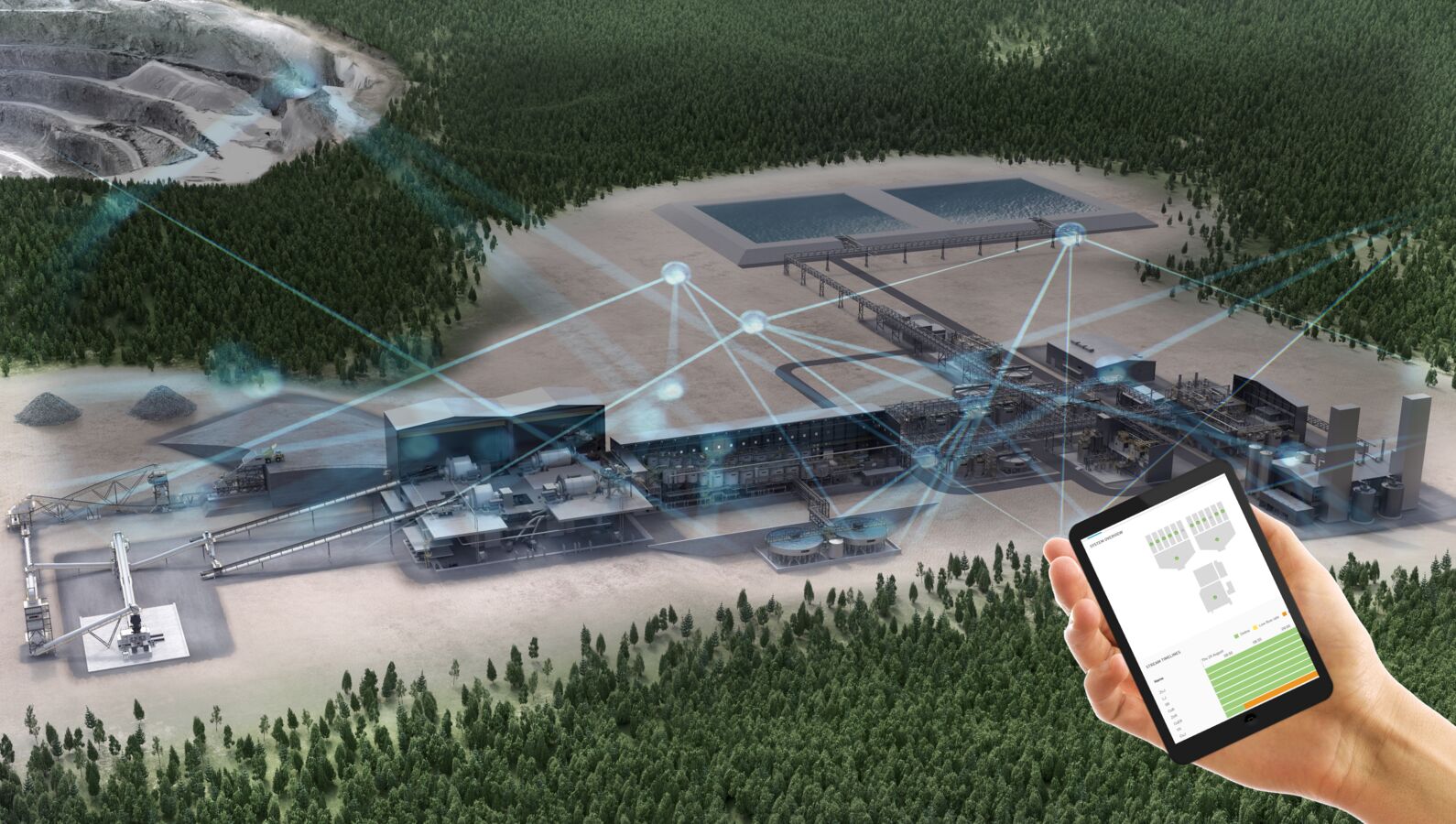

Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

With the strictest standards and tolerances for easy, safer maintenance procedures

With 150 distribution centers worldwide, we supply parts where and when you need them

We are here to help from preparing recommended parts lists to installation to upgrade and beyond

From original to 3rd party parts, to complete kits, we can support your site

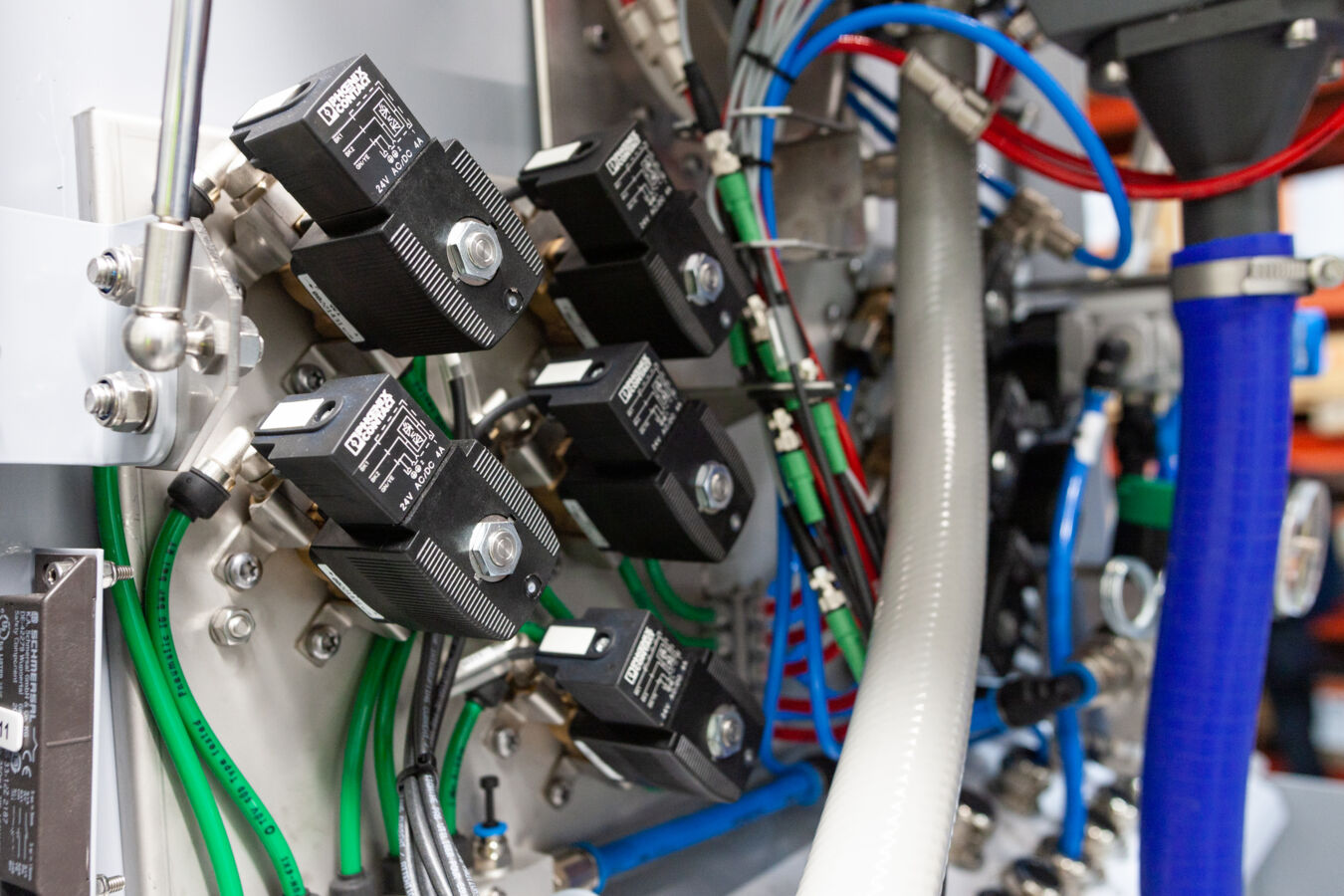

Metso automation equipment is engineered to require only a very limited amount of maintenance to perform high operation continuously. However, the equipment needs attention to retain the maximum operational capacity and ensure the smooth running and optimization of minerals processing.

Availability solutions Ensuring that spare parts are available in the right quantity at the right time is critical for maximizing uptime and reliability. Metso availability solutions are tailored to make sure that unique customer requirements are met when designing optimized spare parts availability.

Availability solutions can range from guaranteeing the availability of operationally critical parts in Metso distribution centers to regular planned deliveries of spares to immediate availability on customer site for high turning wear parts.

How to identify and order spare parts Metso’s local service centers will assist in any service needs. The fastest method of getting spare parts is to use our unique spare part numbers when communicating about the parts. Metso’s professionals in the service centers are happy to help in identifying the needed parts if the spare part numbers are not known by the customer.

We offer the following automation spare parts: