Battery Minerals

Metso is driving a more responsible and sustainable energy transition with its comprehensive coverage of the battery minerals production and recycling processes.

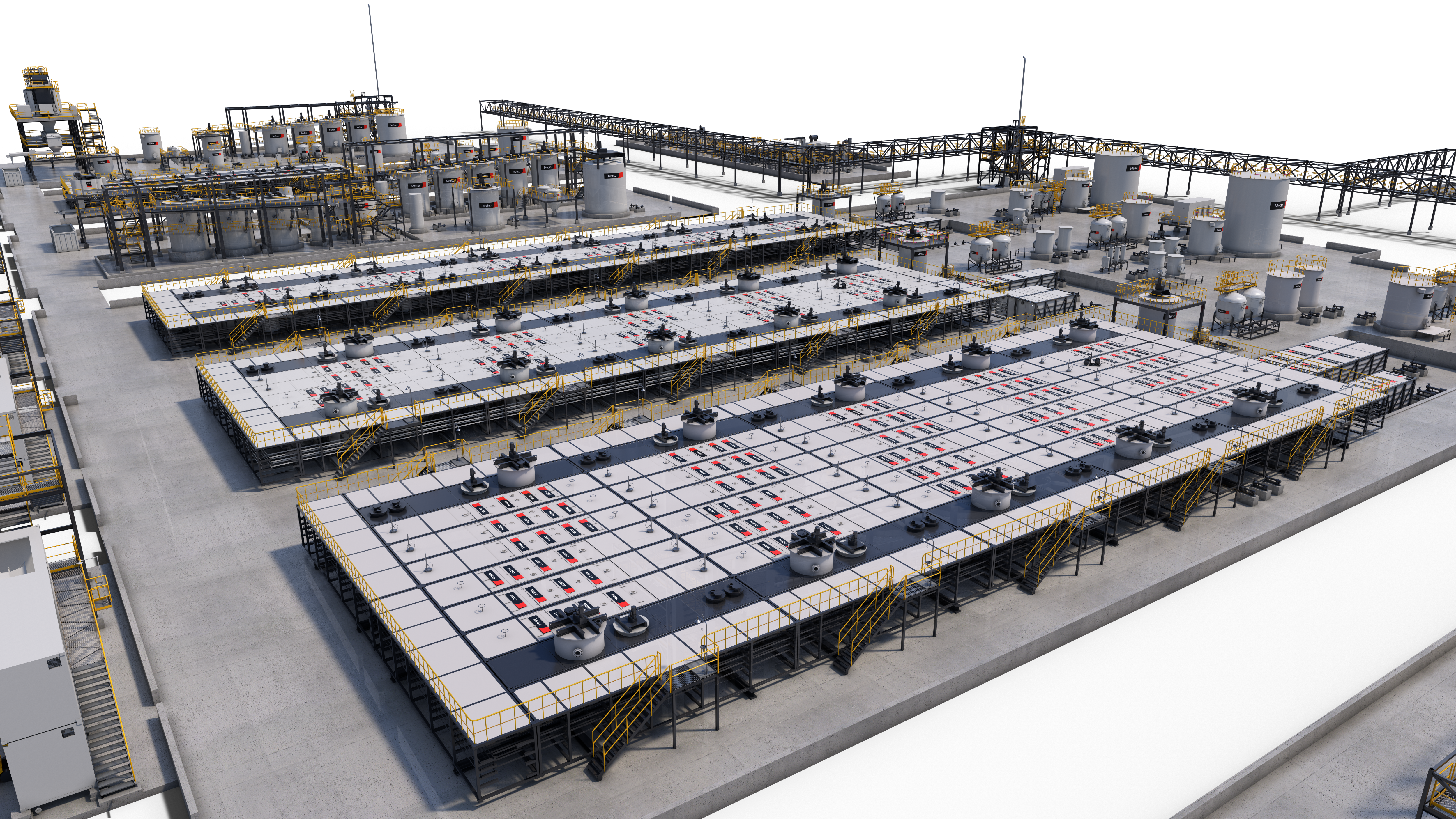

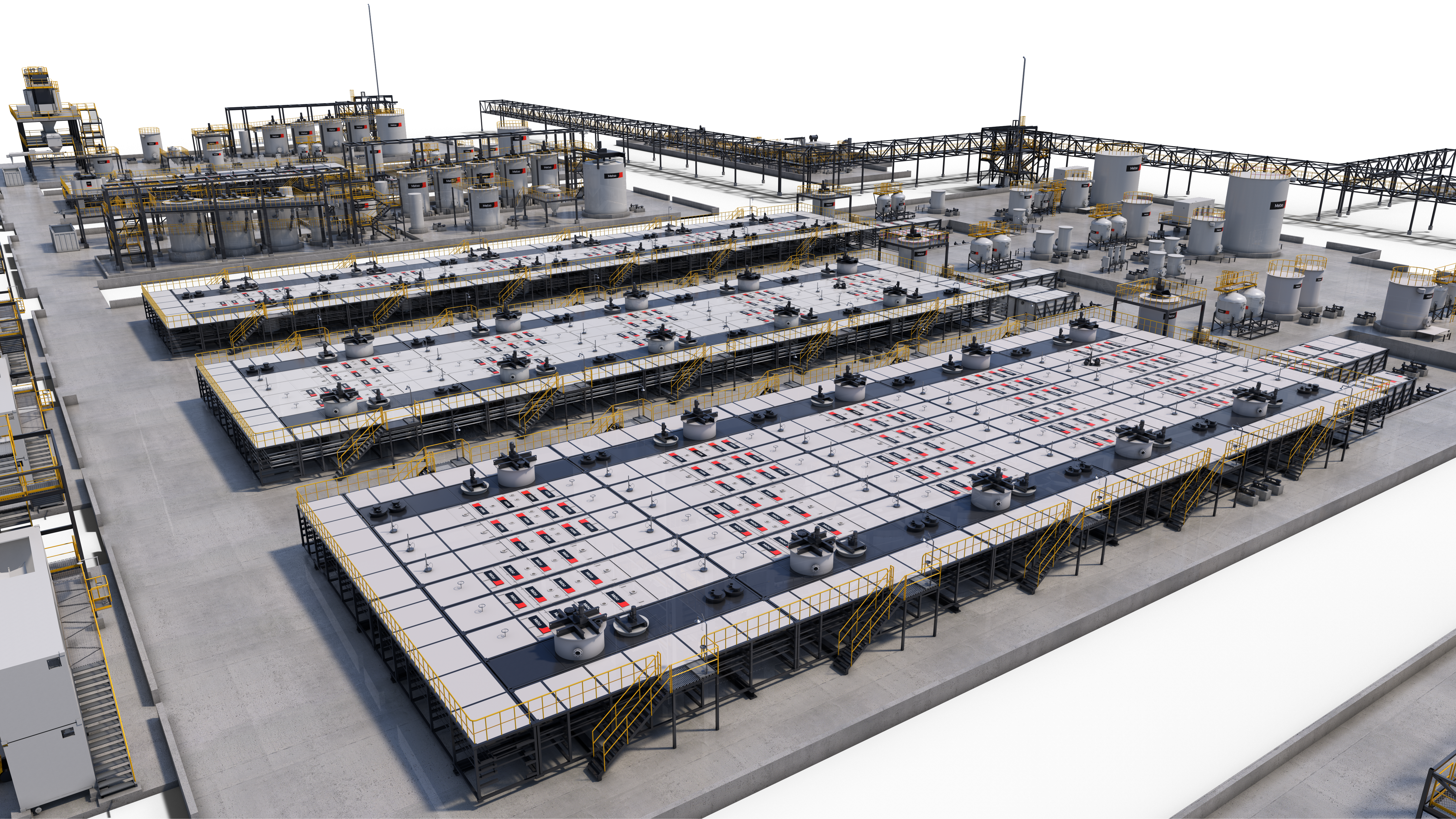

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Advanced technologies to convert the raw materials into Battery grade chemicals

Capability to support sustainable recycling and recovery of raw materials back to front-end of the battery value chain

The flowsheet can be tailored according to the feed materials and desired end products

>60% reduction in embedded carbon

Battery black mass recycling is becoming increasingly important as a supplement to virgin material supply, as well as a way to reduce the carbon footprint of the battery supply chain.

With the increasing demand for zero emission vehicles and the need to create a circular economy, the battery recycling industry is inevitably set to see new and prosperous growth opportunities.

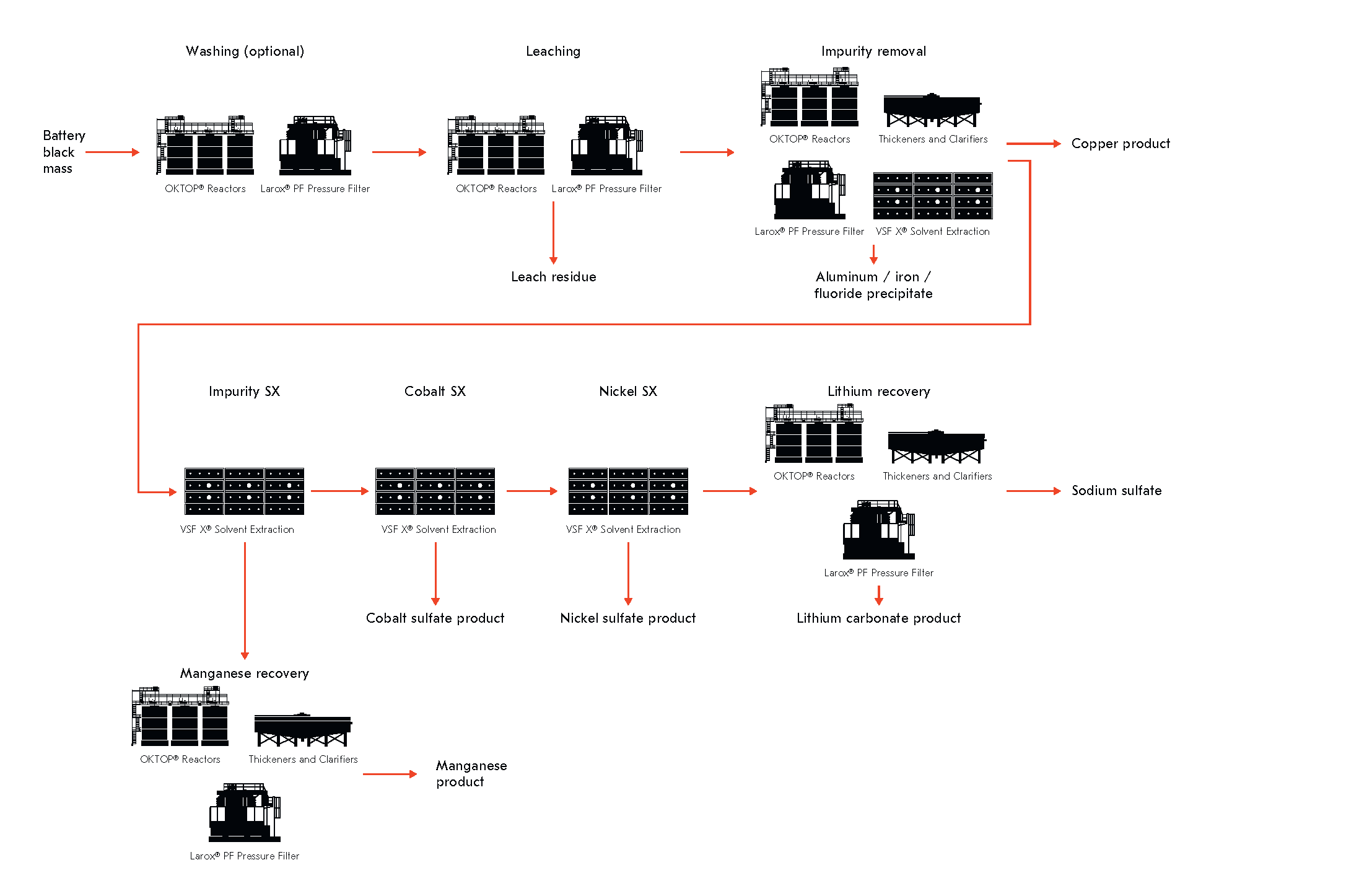

The Battery Black Mass Recycling Process treats batteries after mechanical separation and optional thermal treatment for the recovery of nickel, cobalt and lithium, as well as optionally manganese and copper.

The overall objective is to close the loop on battery raw materials through hydrometallurgical processing. Our decades of process know-how and equipment design enable us to create efficient and responsible methods for recycling and reusing minerals from decommissioned batteries.

We have the robust proprietary technology, knowhow and insight needed to help improve the efficiency and sustainability of the entire value chain. Our comprehensive testing and research capabilities help to design the process from the very early stage.

The process flowsheet can also be tailored according to the feed materials and desired end products with possible phased approach, starting with recovering the most valuable metals.

Our biggest impact is through our customers when they use our technologies and services that help them to achieve their own sustainability and productivity targets.

Sustainable benefits with battery black mass recycling process:

The flowsheet contains Metso Plus core equipment such as:

Battery black mass recycling process is compared with the production of virgin nickel sulfate, cobalt sulfate manganese dioxide and lithium carbonate.