with elliptical motion in combination with 6G

Best technology to replace wet screening in regions with long rainy seasons

Global product support and application expertise

Reducing or eliminating the use of water in the screening process is a growing need for many mining companies. However, removing the process water is a challenge, especially as many plants are located in rainy zones and process ore with a high percentage of moisture.

Metso, in partnership with its customers, has proven that it is possible to adopt a natural moisture screening process. When the mineral processing does not require water processing for ore upgrading, the BSE screening technology eliminates the use and storage of water and leads to a reduction in energy consumption – thanks to the removal of pulp handling equipment (e.g. pumps, dewatering equipment thickeners).

It also reduces other costs, including maintenance and the need to build tailings dams. The elimination of water processing ultimately helps to reduce the potential risk of contaminating the flora and fauna around the mine.

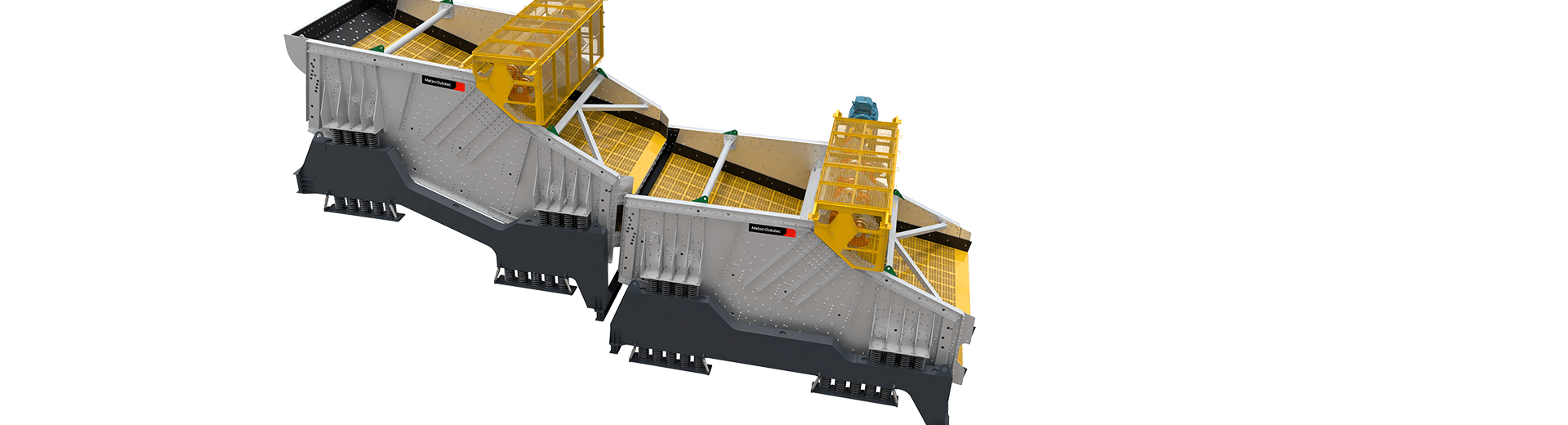

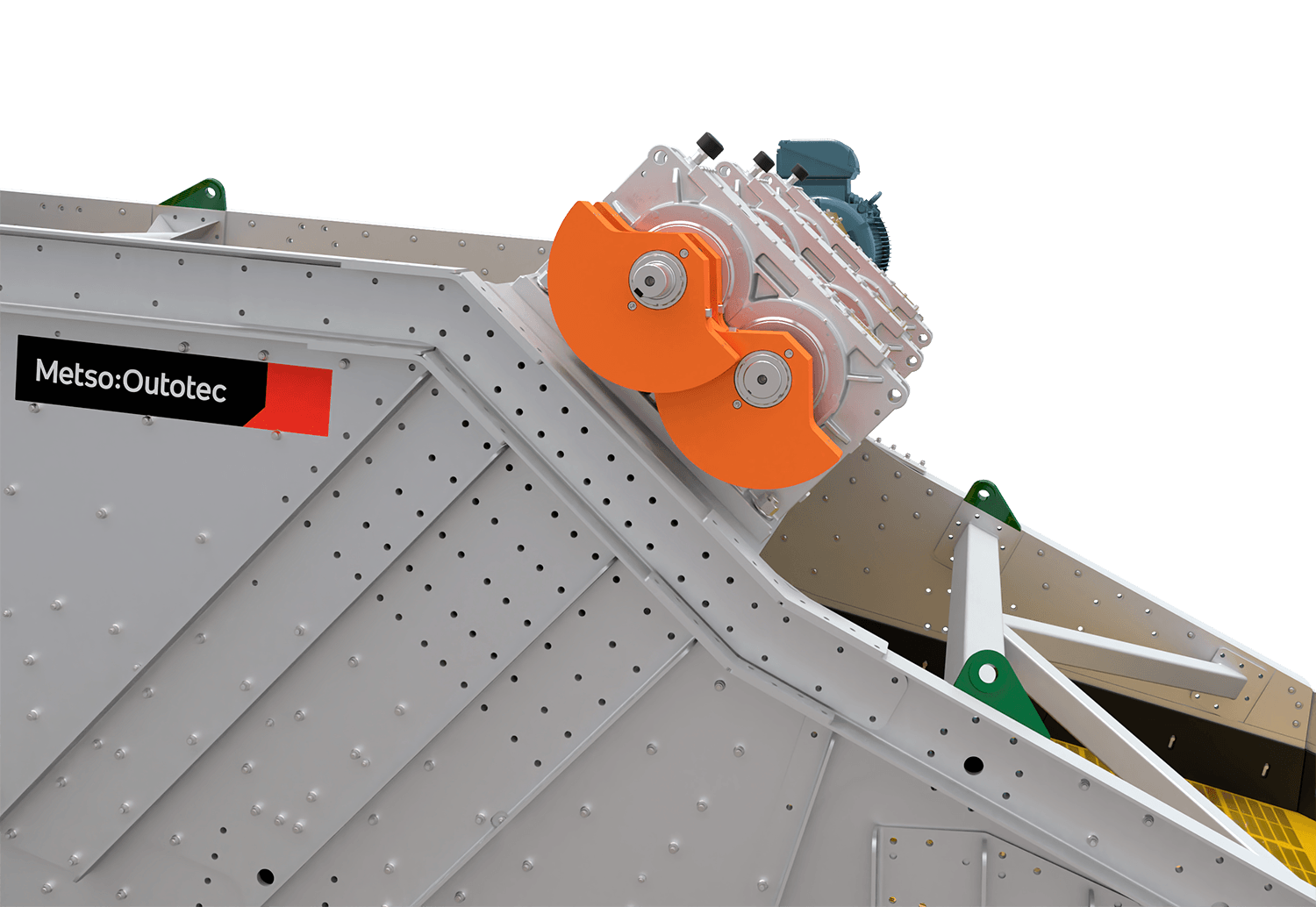

The BSE Series screens with elliptical motion, 6G acceleration, and exciter box are patented equipment. This unique elliptical motion screen design with the well-known box exciter technology enables the construction of large screen sizes, such as 3.6x14.6m (12’x48’). Large screens can lower the construction cost of the screening building structure.

Elliptical motion combines the advantages of circular and linear motion, and particles receives forces in all directions. Elliptical motion and the high transport speed eliminate efficiently blinding and pegging.

All BSE screens are equipped with ML80 or 100 box exciters which enables acceleration up to 6G. Oil-lubricated gear box exciters is well known in the business. The exciters are easily accessible on top of the screen, facilitating removal and maintenance. A reliable solution in combination with easy maintenance offers increased safety.

Technical specification

{{decodeHtmlEntities(field.label)}} |

|---|