How does the Mill Feed Chute work?

For reduced downtime, improved safety and simplified access.

Upgrades help you minimize disruption and maximize uptime

Upgrades and liner lifting tools provide additional safety for workers

Upgrades help to simplify and speed up maintenance

Long-lasting liners, and less waste using WearSense online monitoring

The removable chute cover offers much easier and safer access for wear liner installation and replacement.

Liner design upgrade

Features and benefits

Liftx liner lifting tool for added safety

Labyrinth or inflatable design for various mill configurations.

Inflatable Seal

Allows clearance for installation and maintenance, and quick inflation with air to seal the gap when feed chute is in place.

Labyrinth Seal

Adjustable alignment of feed chute upper section provides robust sealing solution while hinged front panel for easy retraction of feed chute without unbolting upper section.

Gives operators a safe and easy way to access the upper feed chute, inspect the rock-box and perform any maintenance in the area.

Optional add-on to offer an additional access point to the Rock-box for clean out and maintenance.

Easy access for maintenance.

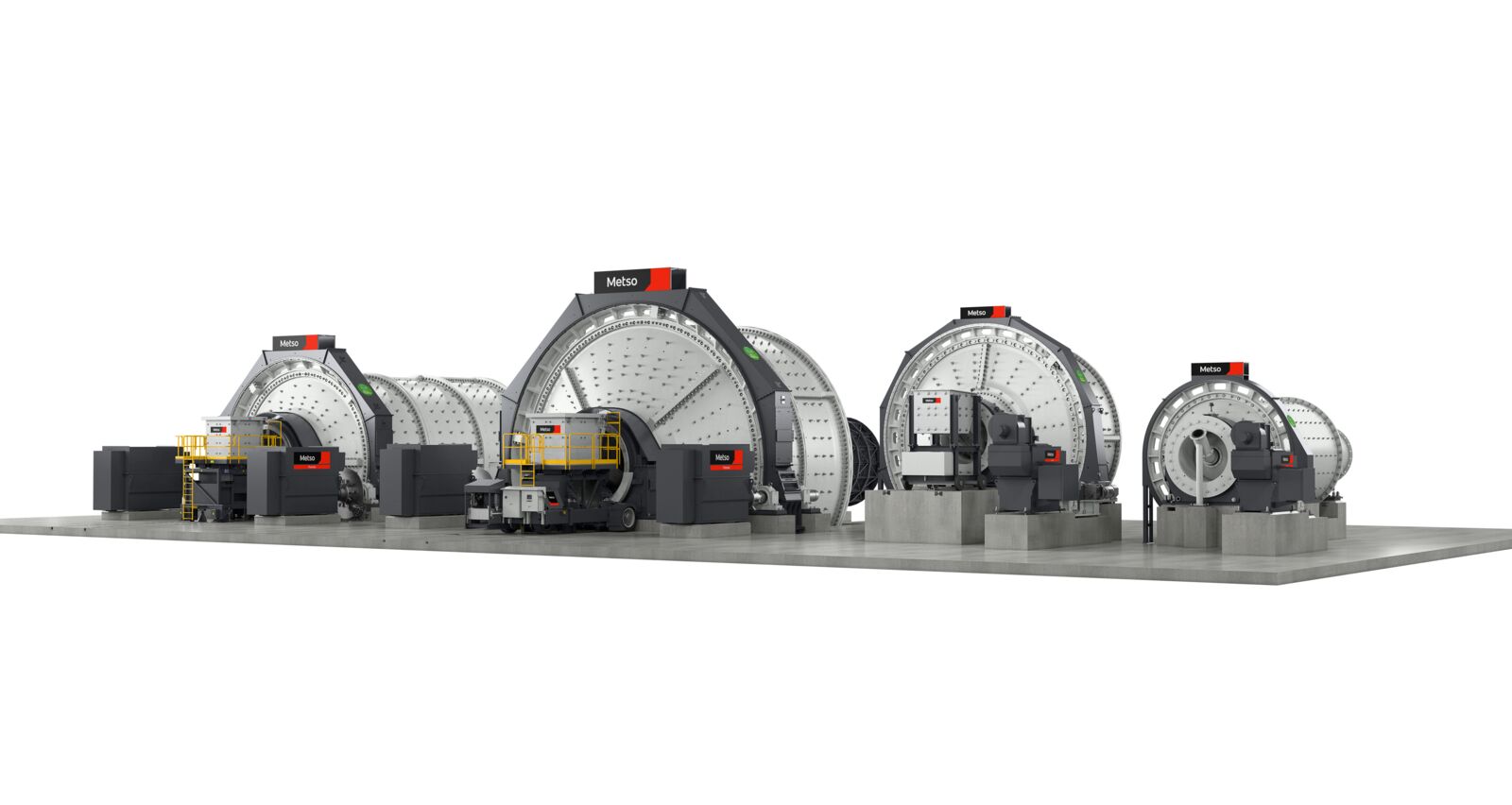

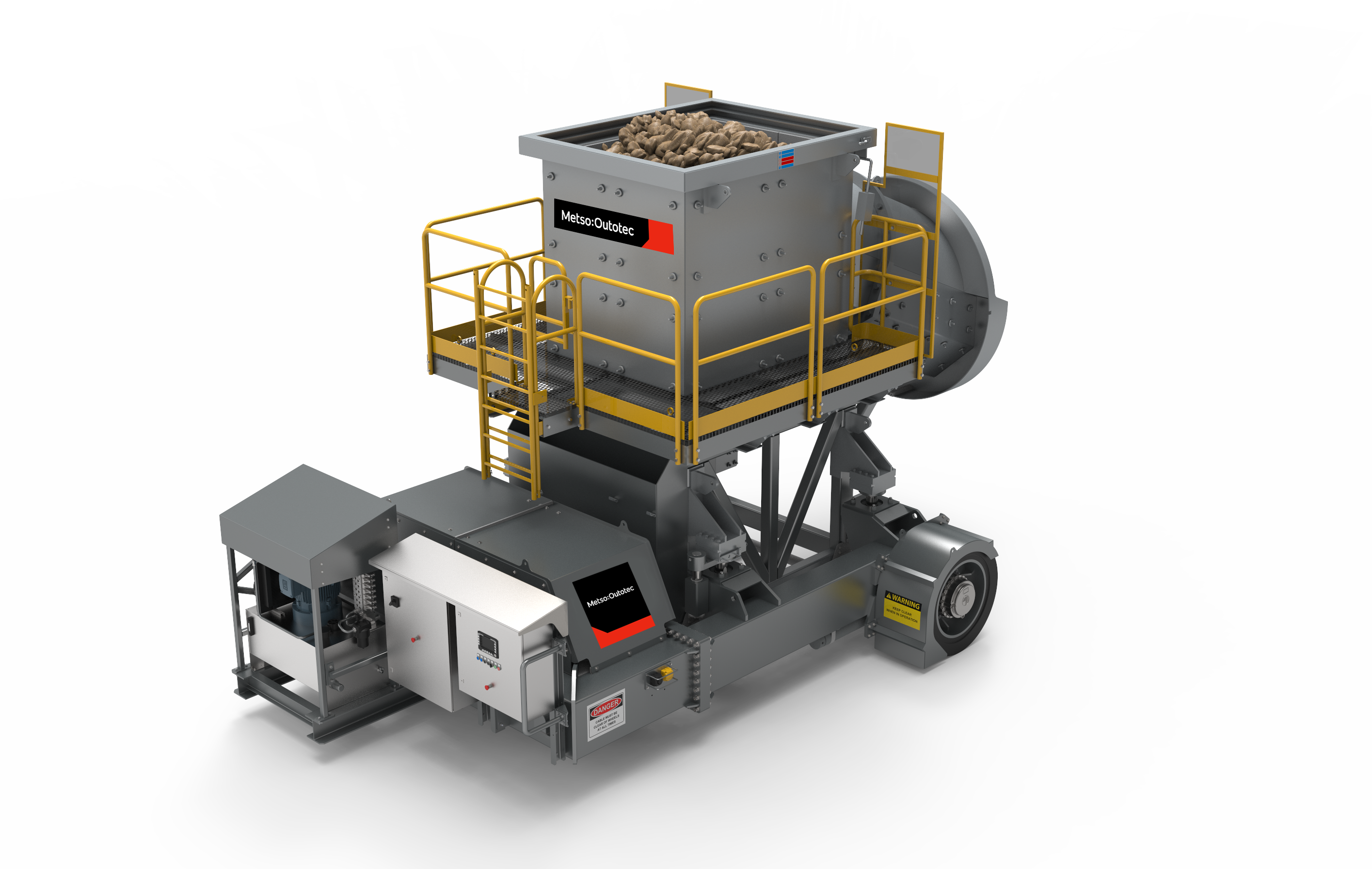

Carriage

Trolley alignment features

Mobile transporter to lift and position a fixed trolley

The MET is equipped with a variety of safety features to monitor loads and is backed by a comprehensive range of support services.

Standard improvement | Optional improvement |

|---|---|

| Leak free upgraded Head Chute interface seal | Winch - with winch connection provisions only |

| Improved access to feed box via a maintenance hatch | Onboard drive - front and back movement only |

| Fixed access platform for easy access to head chute seal and access hatches | Onboard drive - front and back, lateral movement |

| Chute alignment aid features built-in to trolley design | Transporter - provisions for lifting with transporter |

| Easy access to spout liners via removable spout cover | Hydraulic jacks/stands to relieve weight from wheels |

| Centralized flow by using curved liners | Retractable carriage protects wheels while mill is running |

| Superior wear life using high performance wear materials | MO will design according to customer needs |

| Eliminate liner wash by incorporating Gridlock | |

| Improved QHSE using dedicated lifting solutions |