The ColumnCell™ is the result of thorough research, proven expertise and two combined legacy technologies. As a tailored solution, the ColumnCell is customizable to suit every customer’s individual needs.

- Superior metallurgical flotation performance for fine ores

- High concentrate and froth quality

- High availability and high capacity

- Easy and safe operation

- Reduced energy consumption and small plant footprint

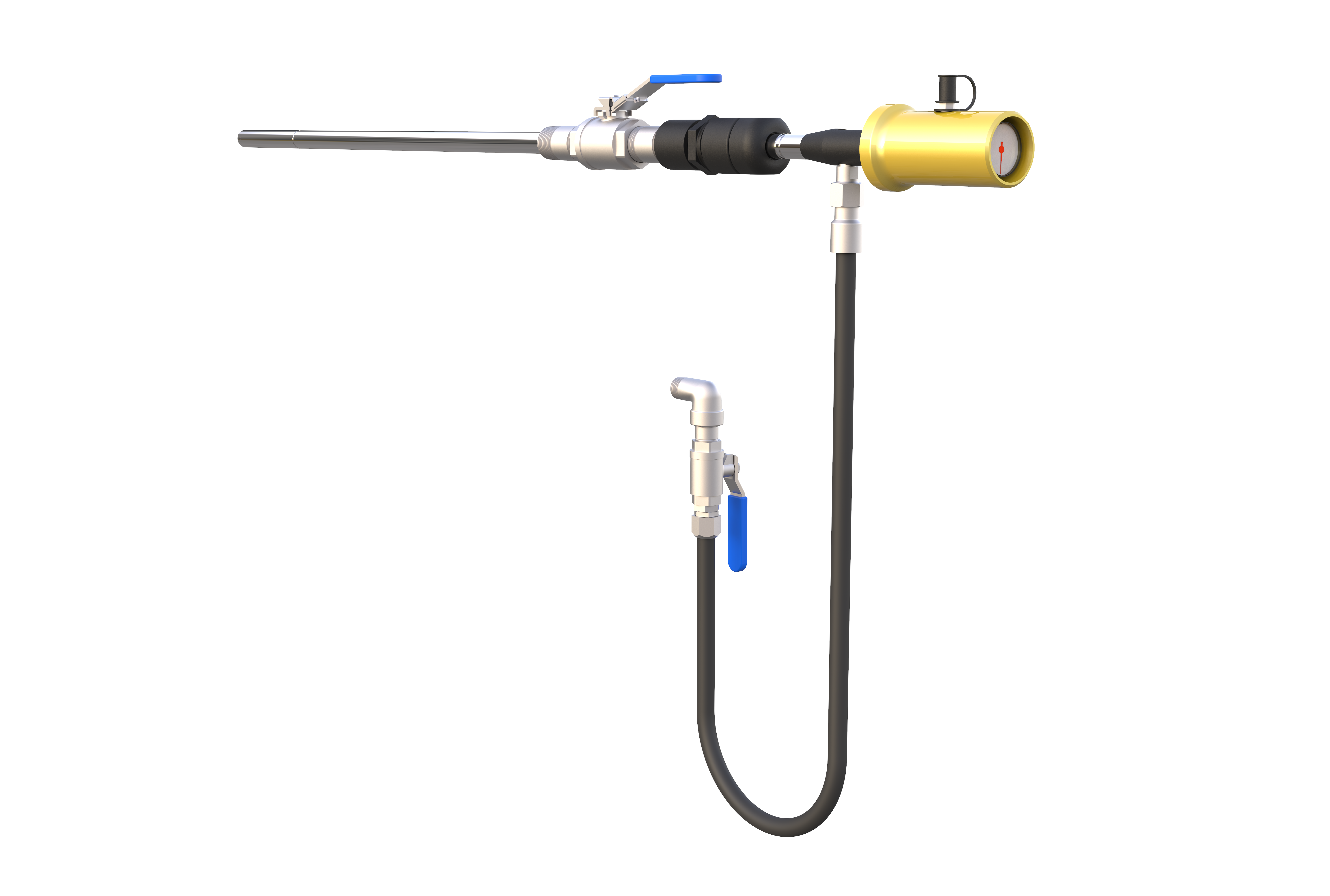

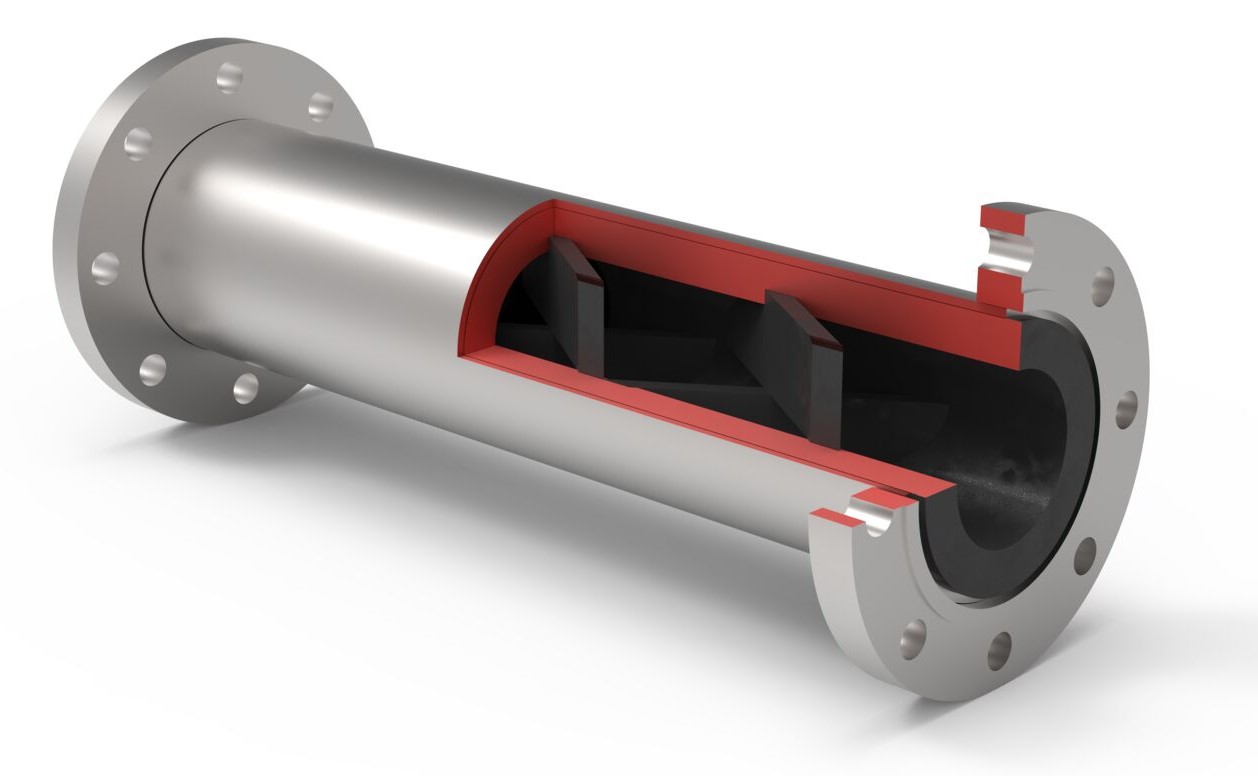

Consists of in-line static mixers and a centrifugal pump.

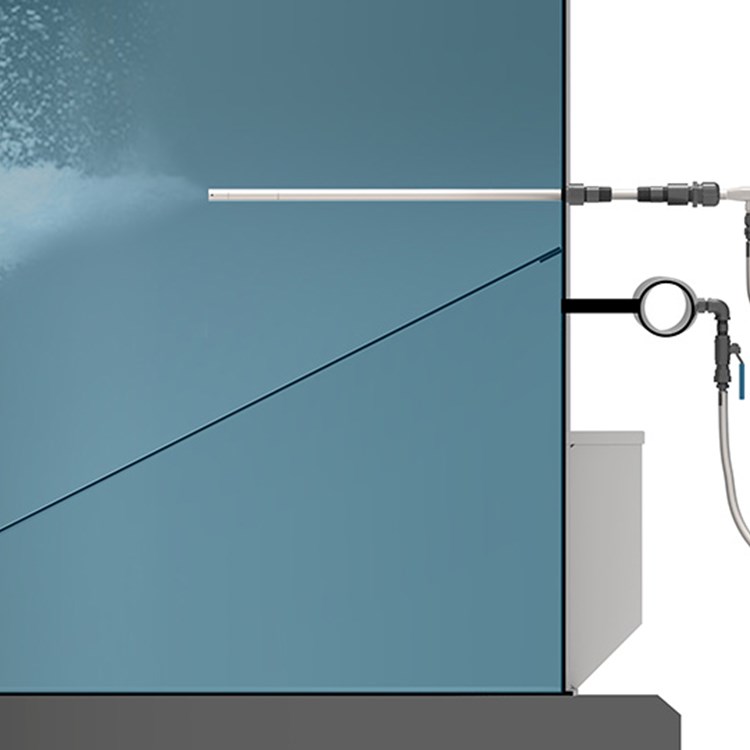

Tailings slurry is pumped from the base of the column through the static mixers, where air and slurry are mixed under high-shear conditions to create bubble dispersion. As the air-slurry mixture passes through the stationary blades located inside the mixer, the air is sheared into very small bubbles by the intense agitation.

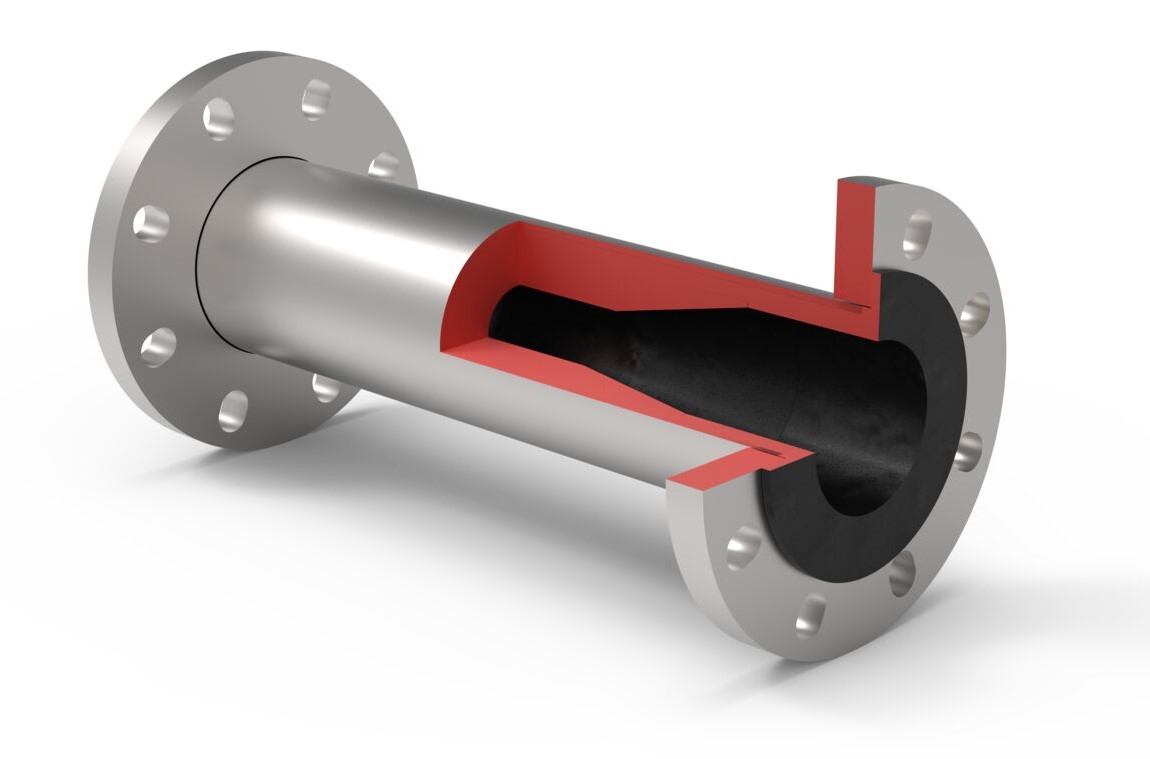

Uses cavitation to generate microbubbles.

A Venturi tube – which promotes cavitation and creates small size bubbles – comprises of a constricted section that is typically centralized within a pipe. After this, the tube gradually returns to the original diameter. Air is introduced before the cavitation constriction, as air injection creates the best bubble size distribution for flotation.

Operates with inlet air pressures between 5-7 bar.

The maximum flowrate of each sparger is determined by the size of the outlet nozzle orifice. The nozzle size and the number of spargers are calculated to suit the specific application. The SonicSparger Jet has up to three different lengths, and in large tanks/columns, they are alternately distributed to provide even air injection through the cross-section area.