Primary dust collection consists of a baffle chamber arrangement, which forms an integral part of the heater expansion chamber. The heated dust collected by the baffle chamber is mixed back with the heated bed product. The exhaust gases are then directed to a common baghouse dust collection system.

Control of the heating operation is automatic. A thermocouple in the fluidized bed controls the power input to the electric elements and hence the thermal requirement of the heater.

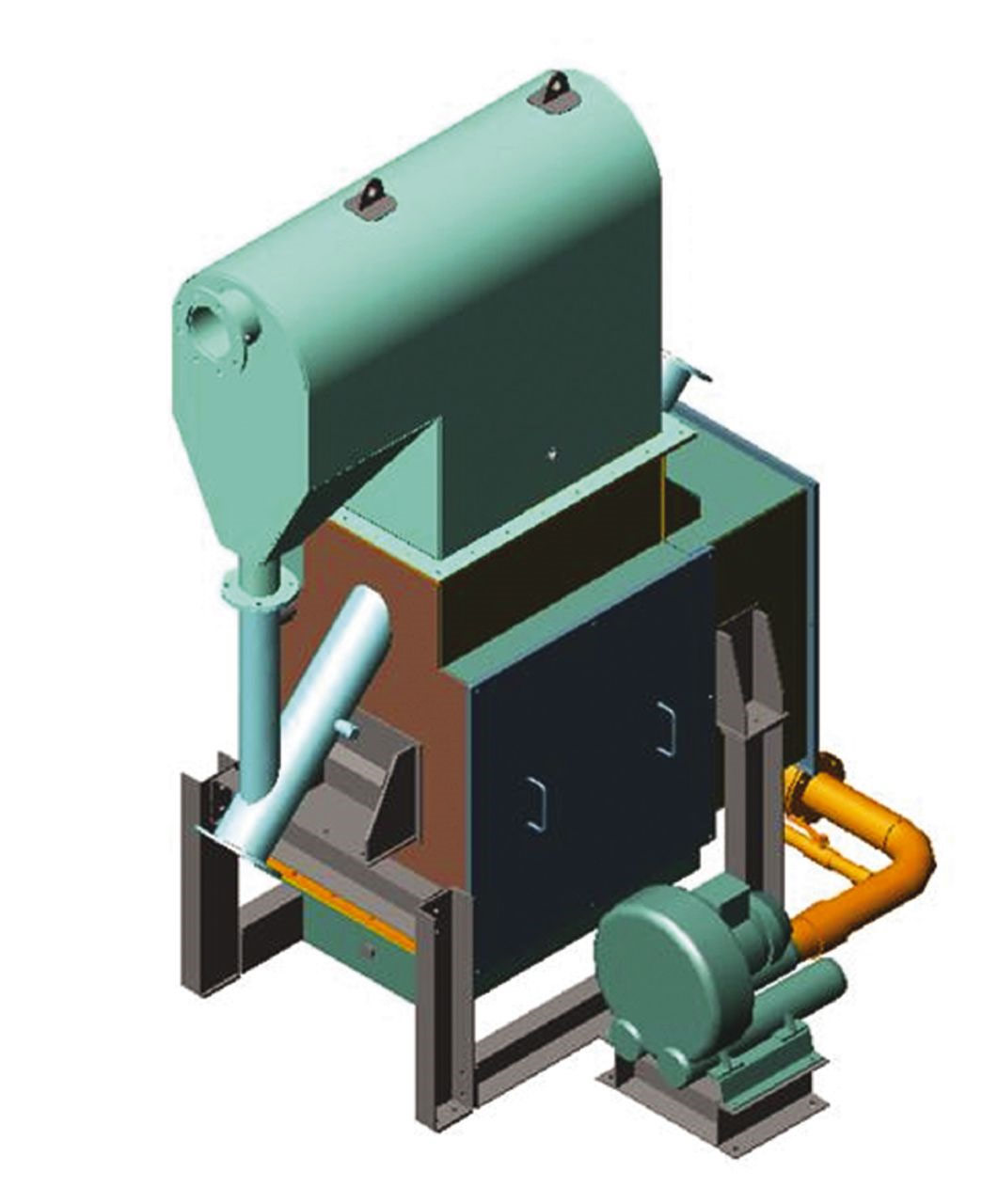

The fluidized bed electric heater consists of a rectangular steel vessel separated by an air distributor or fluoplate. Ambient temperature air from the fluidizing fan is introduced into the lower portion (or windbox) of the vessel and enters the upper portion (or expansion chamber) via tuyeres in the fluoplate. The material to be heated is fed onto the fluoplate where it is fluidized and heated by electrical elements immersed in the bed of material. The heated material is discharged from the heater over a weir, onto a discharge conveyor.

The Metso EH 120 electric heater features high concentration of electrical elements in a relatively small volume (240 kW of energy is generated in the volume of 0.27m3) and hence the thermal inertia of the system is very low.

When the temperature or rate of the feed changes the thermal demand of the heater changes. Because the heat transfer from the elements to the bed is very fast the energy generated by the elements is adjusted immediately thus reducing fluctuations in the product temperature. In most Mineral Separation Plants such a fluctuations are very common. For every second that the product temperature is higher than set by the plant operator unnecessary energy is carried out by the product thus reducing the efficiency of the system.