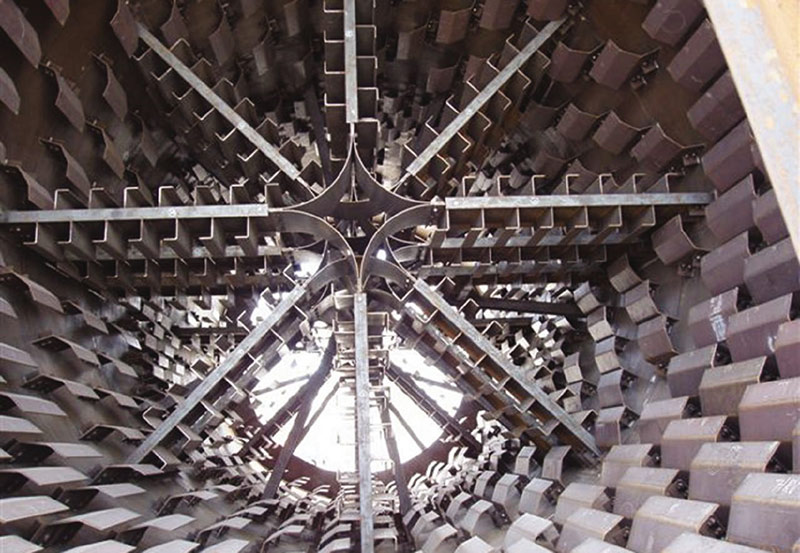

The Rotary Drying and Cooling equipment utilizes a hot gas stream or cold gas stream that mixes with the product. The product is mixed with the air stream by utilizing lifters that shower the product in the air stream. The mechanical lifting aides in breaking clumps, which aides in the drying process. The equipment is set on an incline and conveys material down the cylindrical shaft.

Standard ranges for drying and cooling

| SIZES AND CAPACITIES FOR DRYING |

| Diameter: 1 ft to 24 ft |

| Length: 6 ft to 200 ft |

| Throughput: less than 1T/hr to 1000T/hr and above |

| Moisture reduction: typically drying between 5% to 20% and up to 40% |

| Fuels: gas, coal, oil |

| SIZES AND CAPACITIES FOR COOLING |

| Diameter: 1 ft to 24 ft |

| Length: 6 ft to 200 ft |

| Throughput: less than 1T/hr to 1000T/hr and above |