• Sulfuric acid production

• Ability to process and upgrade lower-quality ores

• Recovery of valuable metals such as antimony

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

• Sulfuric acid production

• Ability to process and upgrade lower-quality ores

• Recovery of valuable metals such as antimony

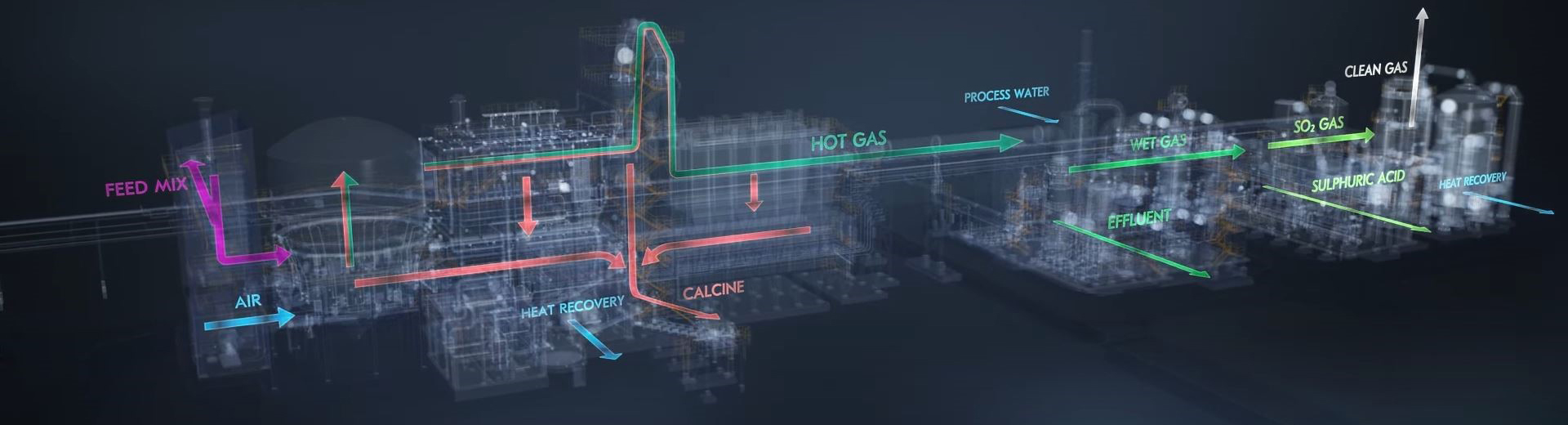

Our copper arsenic partial roasting process is used for removing impurities from feed material. In this process the sulfur is only partially roasted, with the quantity depending on the concentrate analysis and the desired calcine grade. In some cases, partial roasting is used to remove almost all unwanted elements – such as arsenic and antimony – before further treating the calcine. Special equipment is used for cooling and precipitating arsenic trioxide, which can be produced to a very high purity. For copper concentrates, partial roasting is used as a pretreatment step prior to the flash smelting process.

• Arsenic elimination from concentrate: 12% to < 0.3%

• Antimony elimination from concentrate: 1.2% to < 0.2%

• Feed material capacity of up to 600,000 metric tons per annum

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice