Automation interactive tool

Explore different parts of the concentrator plant while clicking on hotspots to learn more about Metso's automation solutions.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

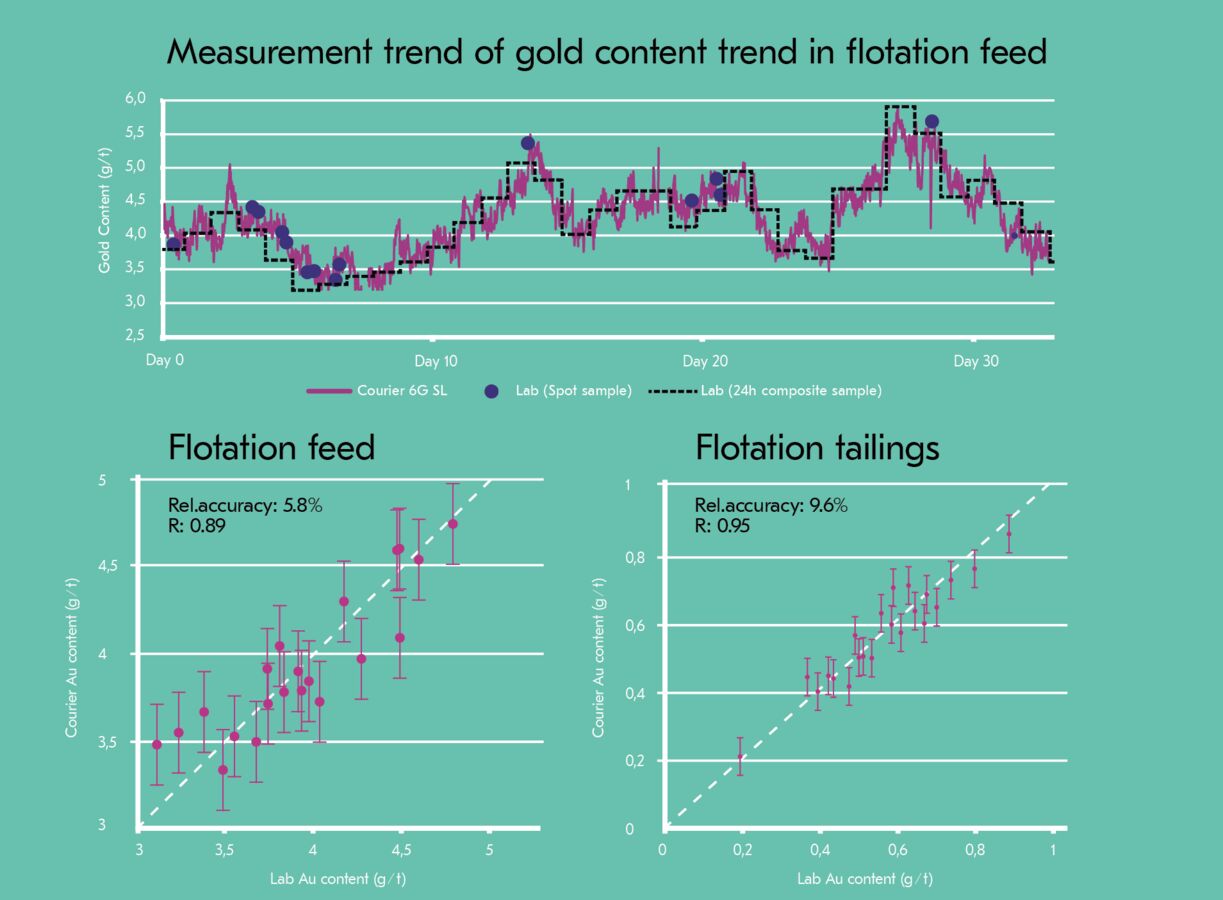

The Courier® 6G SL is a highly-sensitive evolution of Courier® 6X SL analyzer with a higher power X-ray tube and measurement channels optimized for direct on-line measurement of gold in low concentrations from the slurry stream. It offers unprecedented accuracy for process management without interference from the mineral composition changes.

COURIER® 6G SL FEATURES

The Metso Courier® 6G SL is an on-stream elemental analyzer with a high-power X-ray tube and measurement channels optimized for direct measurement of gold in low concentrations from slurry streams.

In addition to gold, Courier® 6G SL can also accurately measure other elements, between calcium and uranium (atomic numbers 20 to 92). This is especially useful in applications where gold is recovered with other valuable metals such as silver or copper.

Courier® 6G SL is a multi-stream analyzer system that can measure up to 24 individual process streams thus enabling total control of complex polymetallic flotation circuits.

A unique combination of Wavelength Dispersive X-ray Fluorescence (WDXRF) and Energy Dispersive X-ray Fluorescence (EDXRF) measurement channels with high-power x-ray tube enable unparalleled measurement performance.

The automatic internal reference measurement guarantees the stability of the measurement against changes in environmental conditions such as temperature.

To compensate for changes in slurry solids content, Courier® 6G SL always measures solids content in addition to elemental content. As an additional benefit, this information can be used to provide a more accurate calculation of real-time recovery, when combined with elemental assay results and volumetric flow measurement. To improve the accuracy of the recovery calculation further, the Metso Courier® 6G SL analyzer can be equipped with a mass-balance data reconciliation module.

The fast, accurate assaying provided by the Metso Courier® 6G SL on-stream analyzer allows you to react immediately to changes in the metallurgical performance of the flotation circuit while simultaneously monitoring the effect of your actions in real-time.

Assays based on strongly filtered or averaged measurements over a long period cannot be used for efficient process control. The extensive time delay between actual process changes and the control action makes the feedback control unstable and reported process trends misleading.

Measurement time in Courier® analyzers can be adjusted individually for each sample stream in order to achieve optimal measurement accuracy and the sampling frequency for process control needs.

Precise sample representation is critical for accurate elemental analysis. In gold applications the importance of sampling is emphasized due to low metal contents. Metso offers a range of sampling solutions starting from low cost process control samplers up to highly representative metallurgical samplers that are compliant with the Theory of Sampling according to AMIRA P754.

To ensure an accurate sample representation is delivered to the analyzer, the primary sample flow is reduced in multiple stages to provide the correct amount of representative sample to the measurement flow cell.

The sample cell ensures that a representative fresh sample is always presented for assaying at the flow cell window surface. The flow cell window is changed regularly to ensure it is clean and free of scaling caused by active slurry contact. Metso’s unique Automatic Window Changer (AWC) provides higher analyzer availability and reduces the manual labor and unnecessary downtime required for window changing.

The analyzer’s local user interface panel features a high-resolution touch screen that displays the most recent assays and assay trends, as well as sample line and analyzer status. It is also used for setting up the functions and parameters of the analyzers.

Assay results can be transferred to the plant automation system (DCS) via most typical communication interfaces such as OPC, Modbus and Profibus.

Courier® 6G SL analyzer provides various connectivity options to plant automation system via Modbus, OPC and Profibus. Courier® 6G SL is equipped with a VPN device to enable remote support with fastest possible response time. Metso security policies and the management framework are broadly compatible with ISO/IEC 27001 and Information Security Forum’s (ISF) Standard of Good Practice.

Please note that the figures below may vary depending on the delivery scope. Contact your local Metso sales representative for exact figures.

The Courier® 6G SL contains several patented and patent pending technologies in several countries.

|

Measurement method |

X-ray fluorescence |

|

X-ray tube |

4 000 W |

|

Measurement channels |

WDXRF and EDXRF |

|

Short-term stability |

0.1% rel. or better |

|

Long-term stability |

Long-term drift compensated against automatic reference |

|

Minimum detection limit |

0.2 g/t for gold |

|

Measurement time (typical) |

30 sec (Au: > 10 g/t) 5 min (Au: 1…10 g/t) 12 min (Au: 0.2 … 1 g/t) |

|

Relative accuracy (typical) |

2 – 5 % (Au: > 10 g/t) 4 – 8 % (Au: 1…10 g/t) 10 – 15% (Au: 0.2 … 1 g/t) |

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice