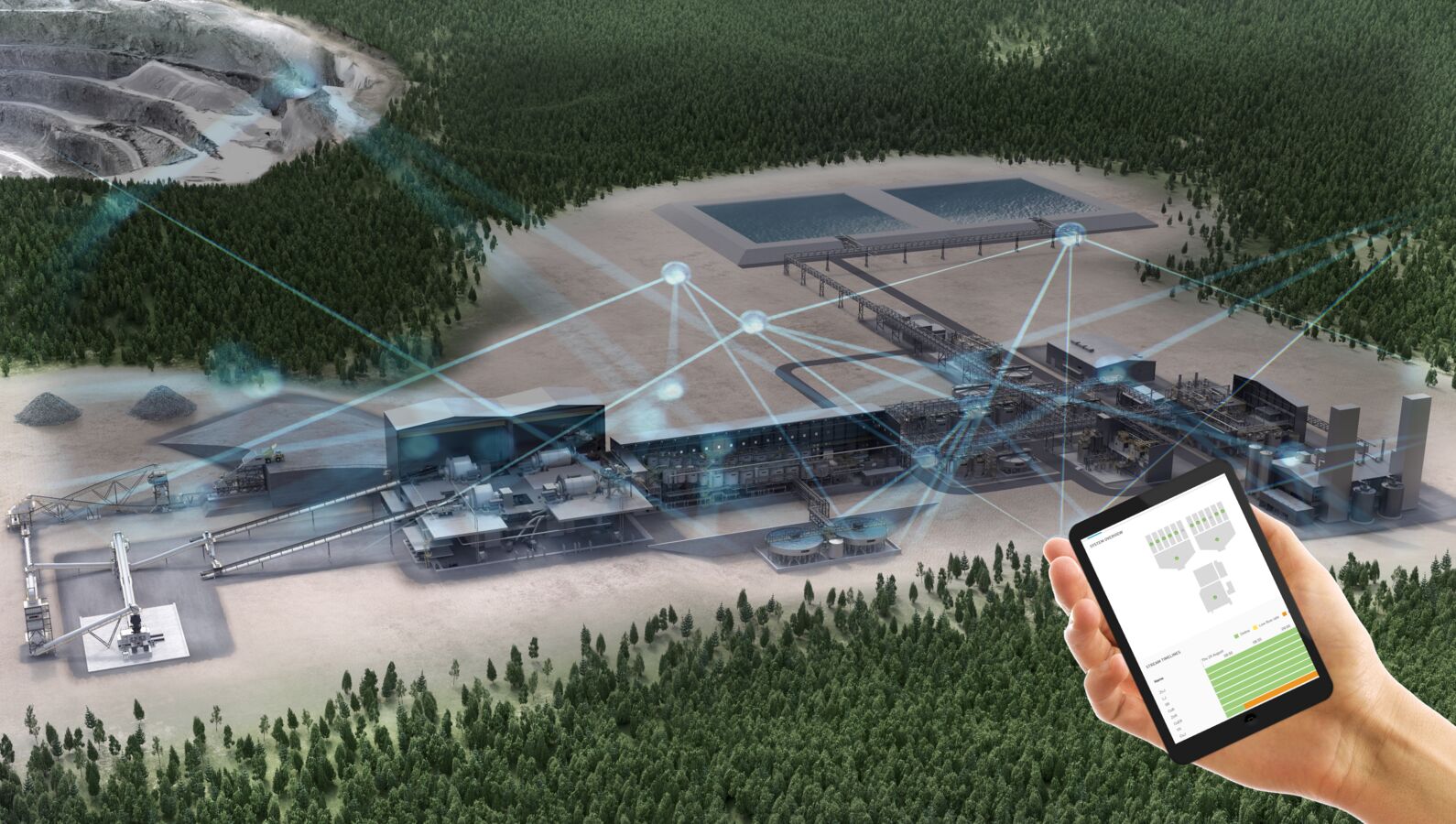

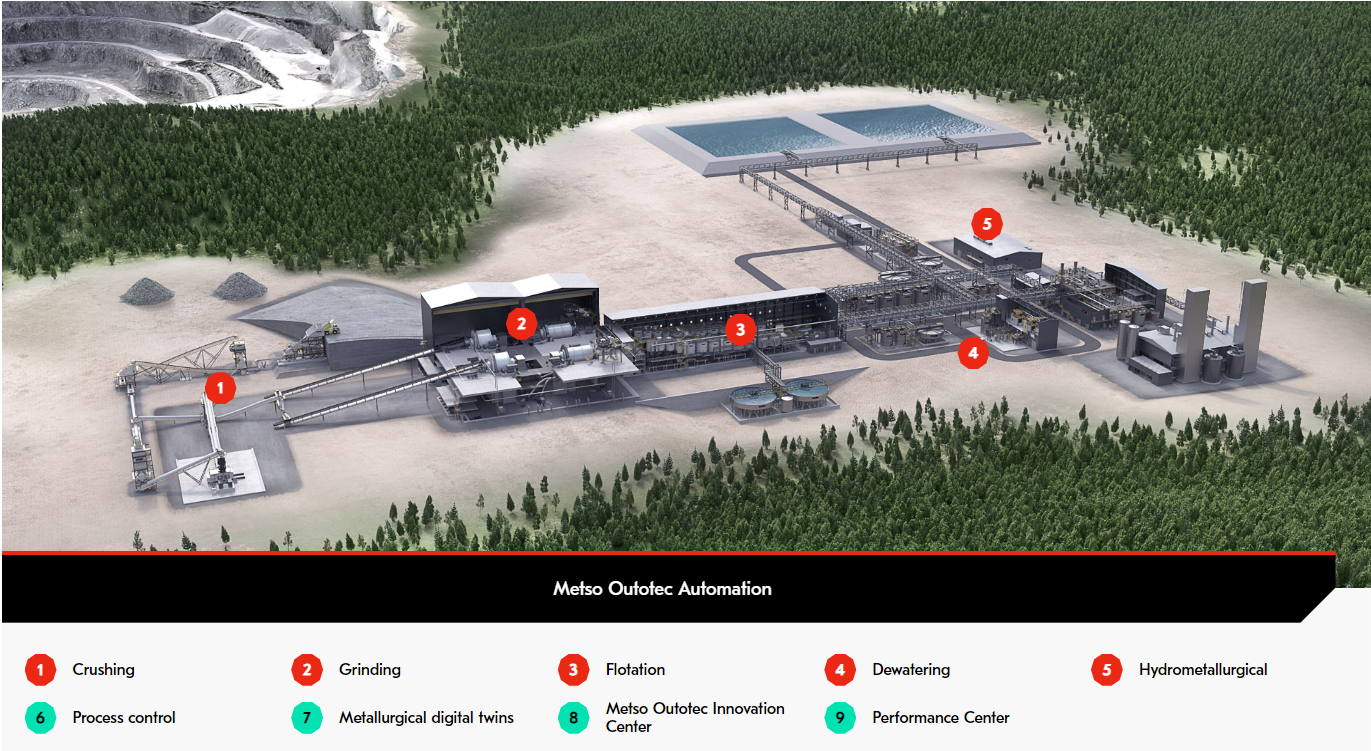

Automation interactive tool

Explore different parts of the concentrator plant while clicking on hotspots to learn more about Metso's automation solutions.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

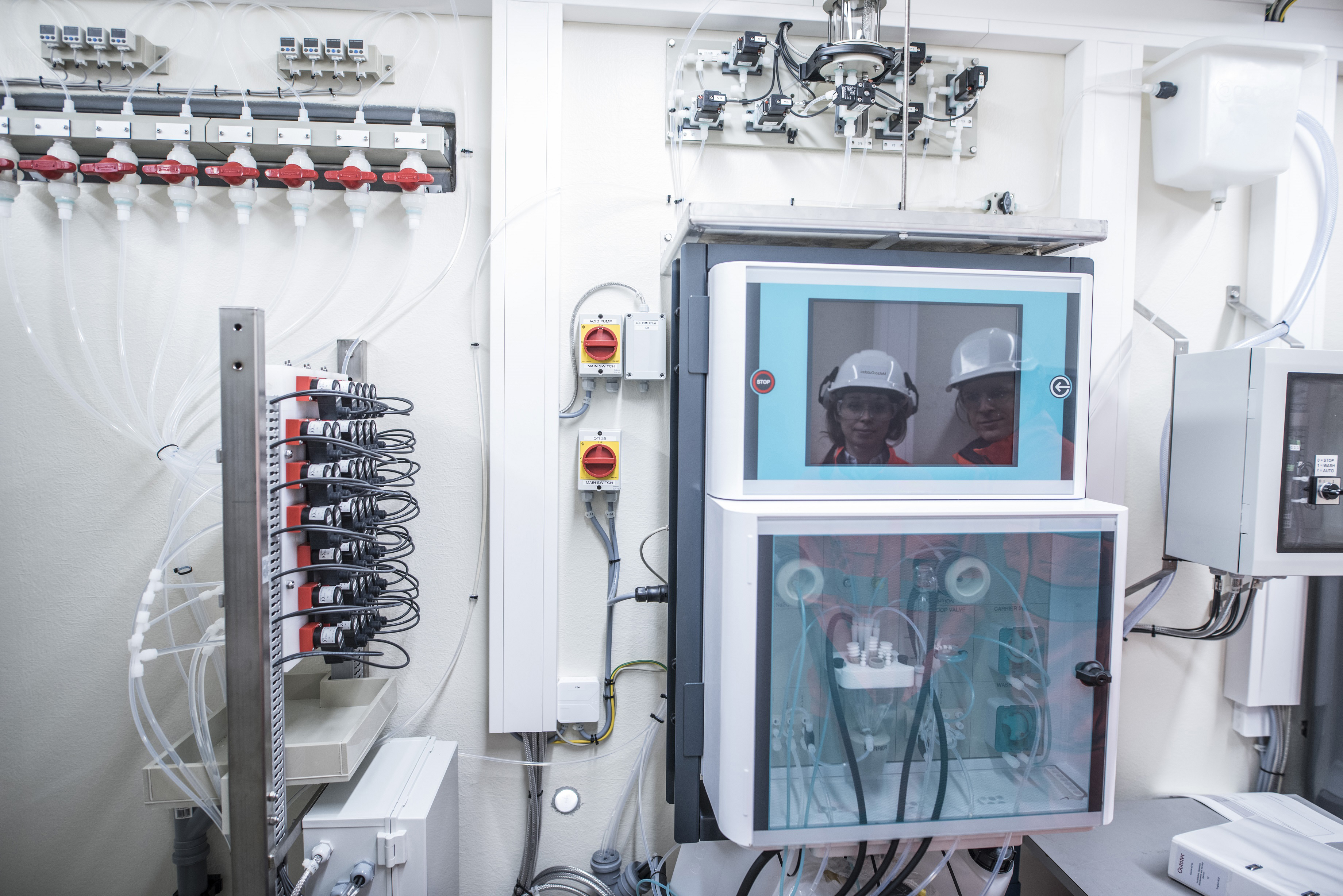

This high-performance on-stream solution analyzer ensures consistent sampling and analysis for hydrometallurgy process management and monitoring. This results in savings in assaying and metallurgical sampling costs, while ensuring repeatability for accurate analysis. Frequent sampling and analysis also contributes to a more stable process and rapid response capabilities for efficient control.

The Courier® HX system analyzes samples from hydrometallurgical processes using high-performance X-ray fluorescence technology. It performs elemental analyses and is supplemented by OTI titrators to analyze ionic contents, such as acid. Samples are taken from the process using fast loops or batch sampling to ensure continuous availability of fresh samples. The analyzer comprises four main components: the analyzer probe, the probe control set, sampling equipment, and the analyzer management station PC.