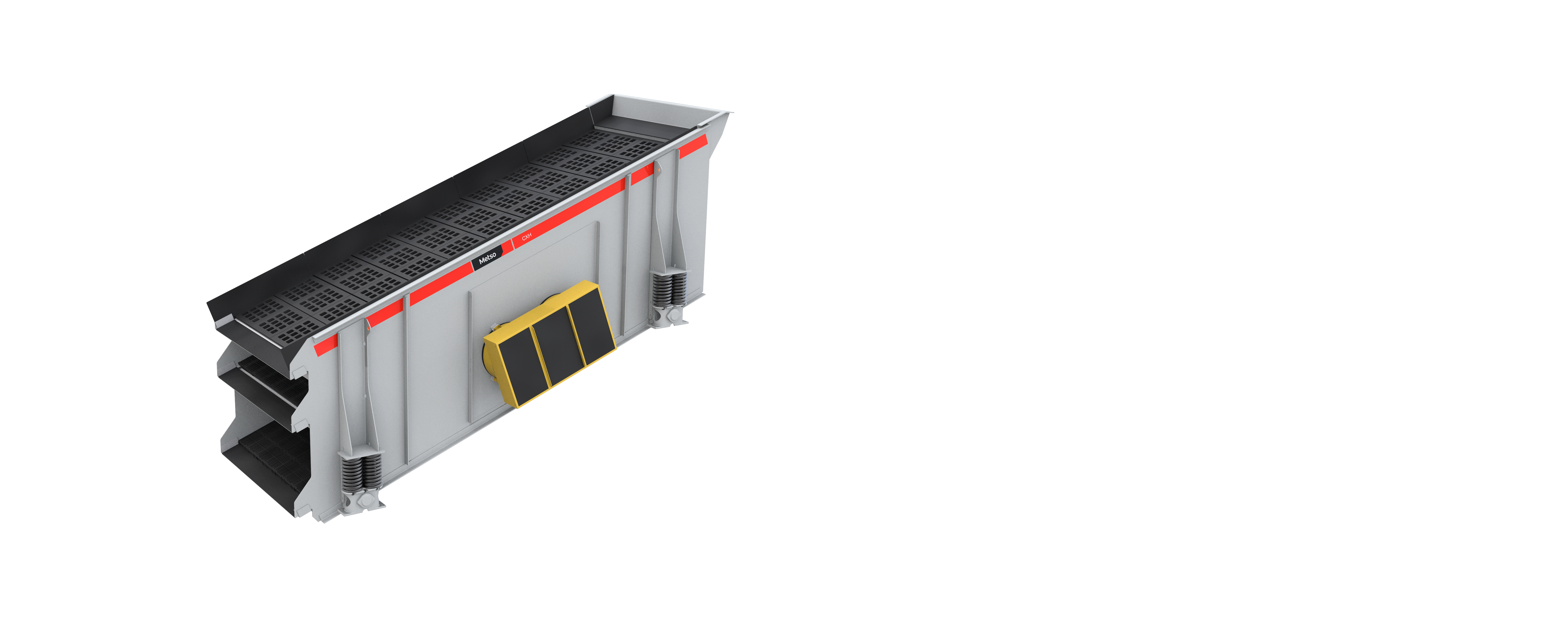

The circular motion characteristics of the V100 series mechanisms make the CSH screen well suited for high efficiency, large-size separations.

Placement of bearings reduce overall stress, reinforced side plates add strength and oil-lubrication means cooler running and less maintenance.

Same footprint as Ripl-Flo - easy to upgrade to today’s standards.

Technical information

Model | Decks | Mechanism | Motor power | Screen dimensions* | Screen area* |

|---|---|---|---|---|---|

| CXH6x16 |

2 | V140 | 15 kW / 20 hp 18.4 kW / 25 hp | 1.8 x 4.9 m / 6 x 16 ft | 8.9 m² / 96 ft² |

| CXH6x20 | 2 3 | V140 V160 | 18.4 kW / 25 hp22 kW / 30 hp | 1.8 x 6.0 m / 6 x 20 ft | 11.15 m² / 120 ft² |

| CXH7x16 | 2 3 | V140 Dual V140 | 18.4 kW / 25 hp 15 kW / 20 hp (x2) | 2.1 x 4.9 m / 7 x 16 ft | 10.4 m² / 112 ft² |

| CXH7x20 | 2 3 | V160 Dual V140 | 22 kW / 30 hp 18.4 kW / 25 hp (x2) | 2.1 x 6.0 m / 7 x 20 ft | 13 m² / 140 ft² |

| CXH8x16 | 2 3 | V160 Dual V140 | 22 kW / 30 hp 15 kW / 20 hp (x2) | 2.4 x 4.9 m / 8 x 16 ft | 11.9 m² / 128 ft² |

| CXH8x20 | 2 3 4 | V160 Dual V140 Dual V160 |

30 kW / 40 hp | 2.4 x 6.0 m / 8 x 20 ft | 14.8 m² / 160 ft² |

| CXH8x24 | 2 3 | Dual V140 Dual V160 | 15 kW / 20 hp (x2) 22 kW / 30 hp (x2) | 2.4 x 7.3 m / 8 x 24 ft | 17.8 m² / 192 ft² |