The discharge device is controlled by measuring furnace differential pressure and operates as a variable cross-section valve. We developed the first CFB calciner in the early 1970s. Metso has designed and constructed 51 calciners with continuous developments and innovative material selection and design over the past five decades. We possess a proven track record with project execution excellence globally, with most projects delivered as EPC contracts.

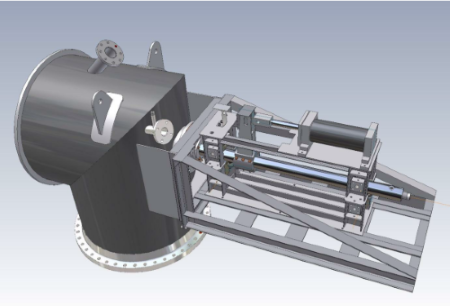

Our latest-generation discharge device is embedded in the rich history of Metso alumina calcination and has been developed to reflect a state-of-art Metso design.

Features

- Enhanced material selection for lance tip, lance tube, and nozzle bricks in alignment with plant temperature and customer preferences

- Optimization of Cv value for a variable cross-section

- Improved actuator control using the latest pneumatic actuator and positioner design

- Compatible with existing communications protocol (4-20 ma + Hart, Fieldbus, etc.) refining feedback

- New center purging air design embedded in the lance tube, eliminating manual purging lance, or can be used in combination with manual purging lance

- Incorporates the latest machine safety regulations

The new discharge device has shown increased plant performance, availability, and safety. Product quality and homogeneity are improved by stabilizing the furnace inventory. The device's longer life span and components save costs and reduce maintenance with fast and easy device exchange.

The additional features and longer life span of the device and components save costs and reduce the maintenance period with a fast and easy exchange of the new device.