10 different filter sizes

Low operating pressure, low operating cost

Up to 15% less energy usage due to low operation pressure, long cycle time and lacking of moving parts

Up to 90% reduced water consumption due to use of filtrate in filter back wash

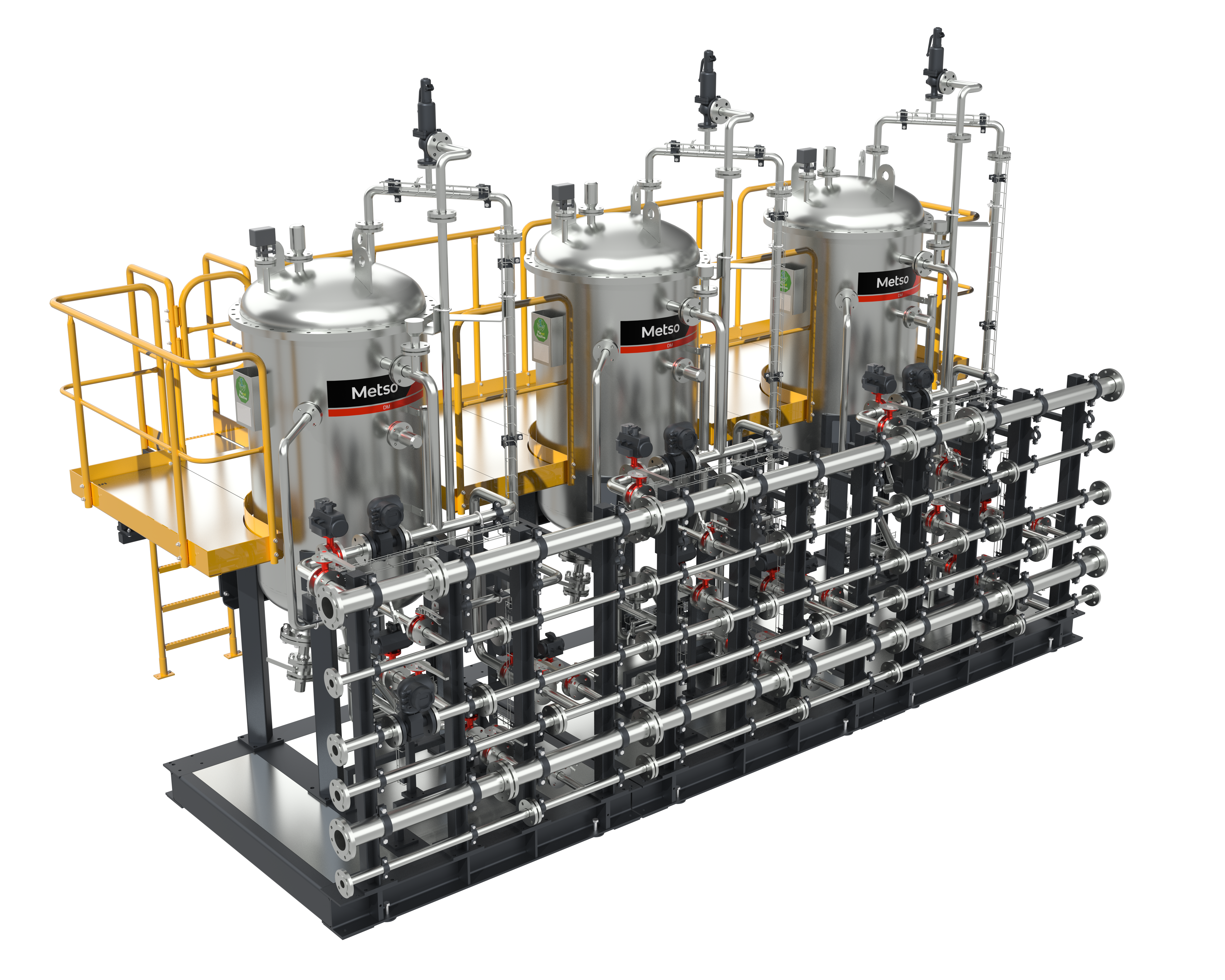

Our filter relies on the proven dual-media concept and can be delivered as an integral part of our solvent extraction and electrowinning (SX-EW) technology or as a stand-alone solution.

- Uses SX-EW technology expertise

- Offers high-quality filtration

- Gives you low operating costs

- Enables fully automatic operation

- Has high capacity and expandability

- Results in minimal maintenance costs

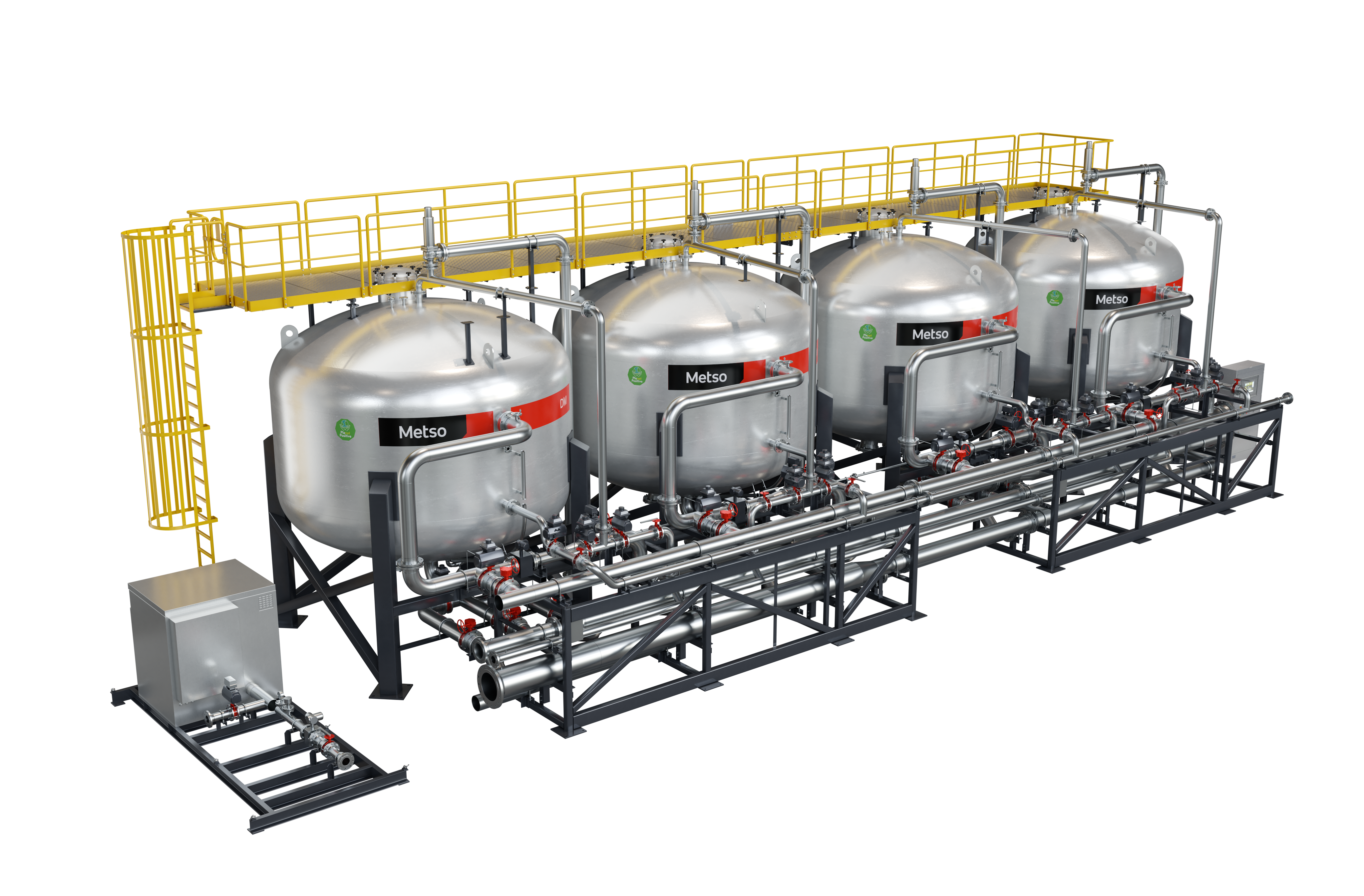

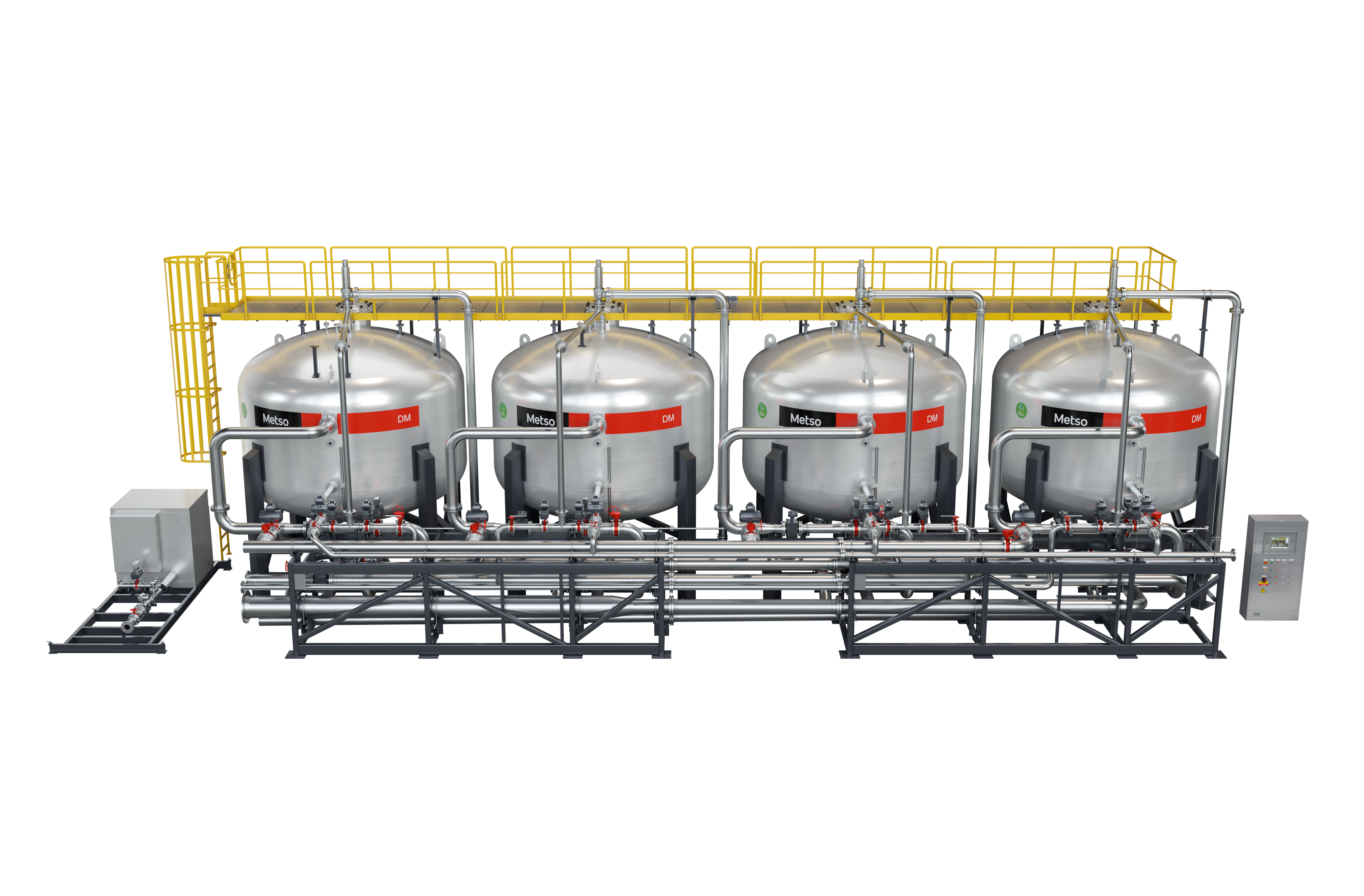

The latest addition to the DM (Dual Media) filter family is a modular DM1000 filter designed to complement the existing DM filter series for increasing need of battery metal processes’ filtration.

Benefits:

- Fully modular design

- 1-4 filters in a row

- Easy expandability

- Ready assembled on a mounting skid

- Fully containerized transportation

- Quick and safe site assembly

- Fully automatic operation

Read more from the DM1000 leaflet available in the downloads section.

Applications

Metso’s filtration expertise is built on almost one hundred years of R&D and process knowledge, and is supported by the company’s globally unique Dewatering Technology Center (DTC) in Lappeenranta, Finland. The DTC plays a crucial role in Metso’s filtration solution innovations and acts as a hub for close university cooperation related to separation technology research. Metso has performed over 14,000 filtration tests and has delivered over 5,000 filters around the world.