Get Smelting Newsletter!

Our newsletter covers all aspects of modern smelting community including experiences from around the world, technology innovations, market information & much more.

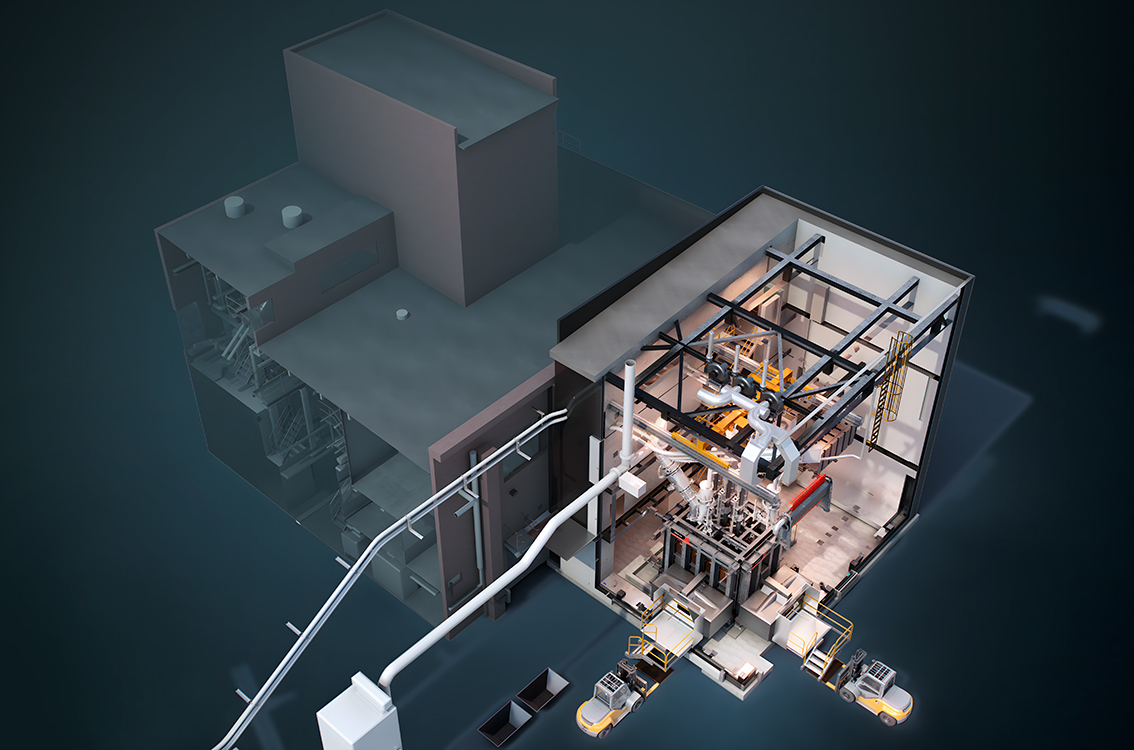

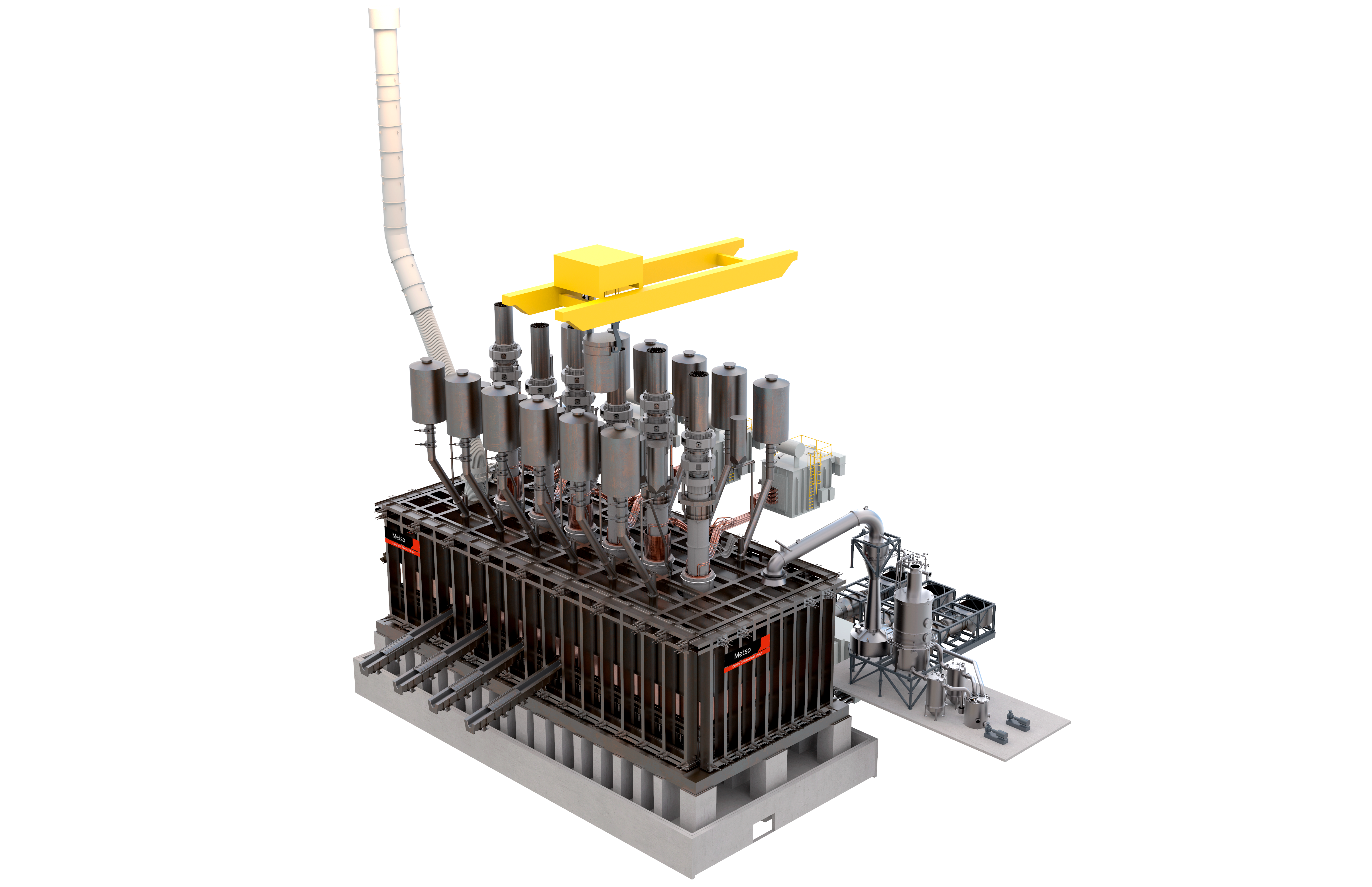

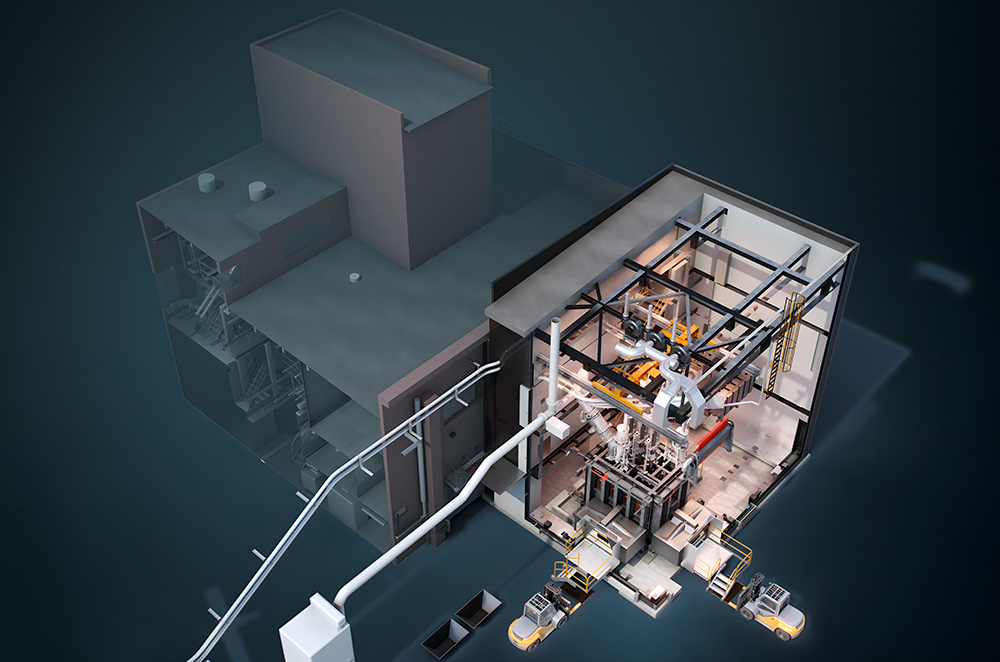

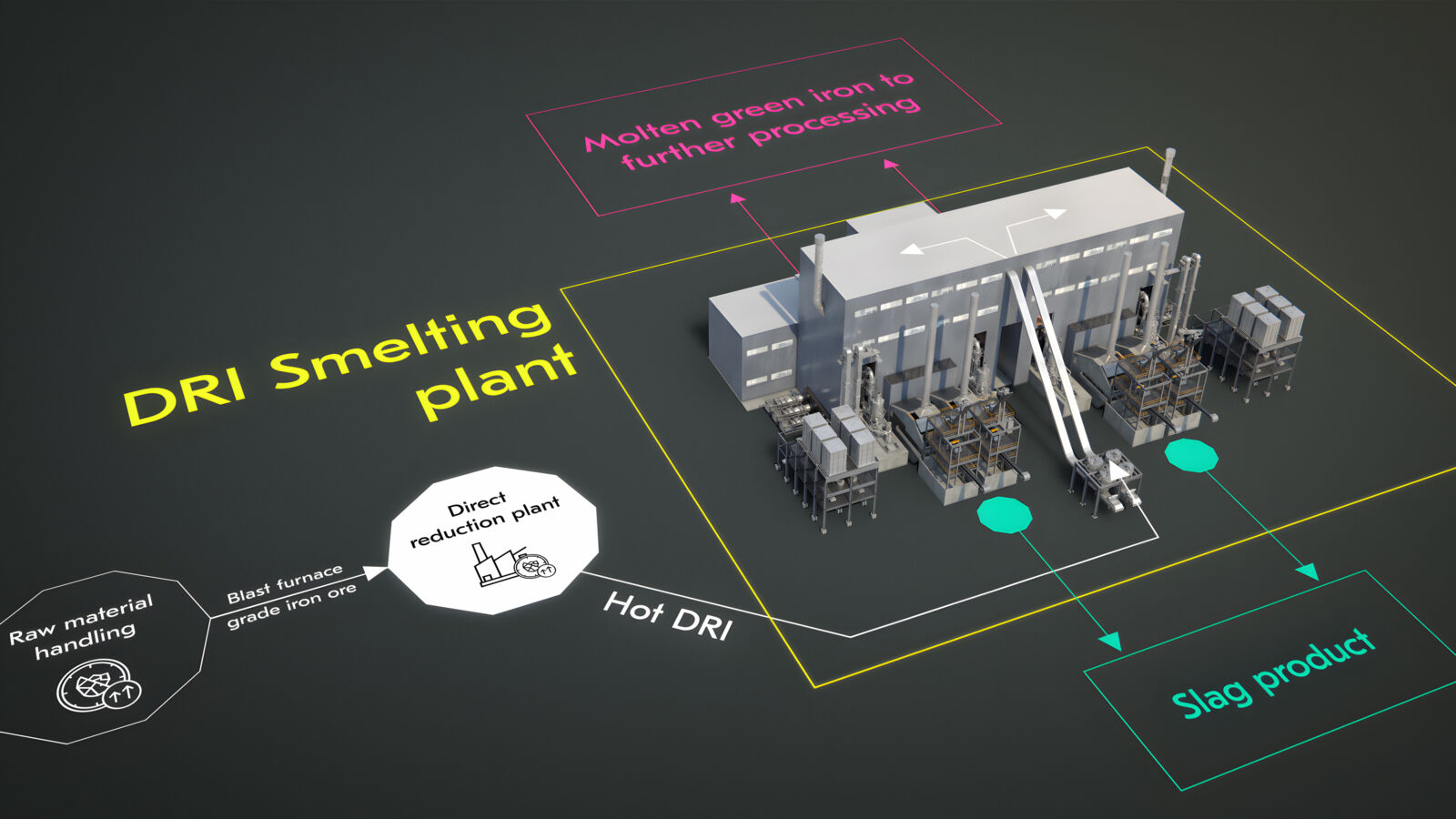

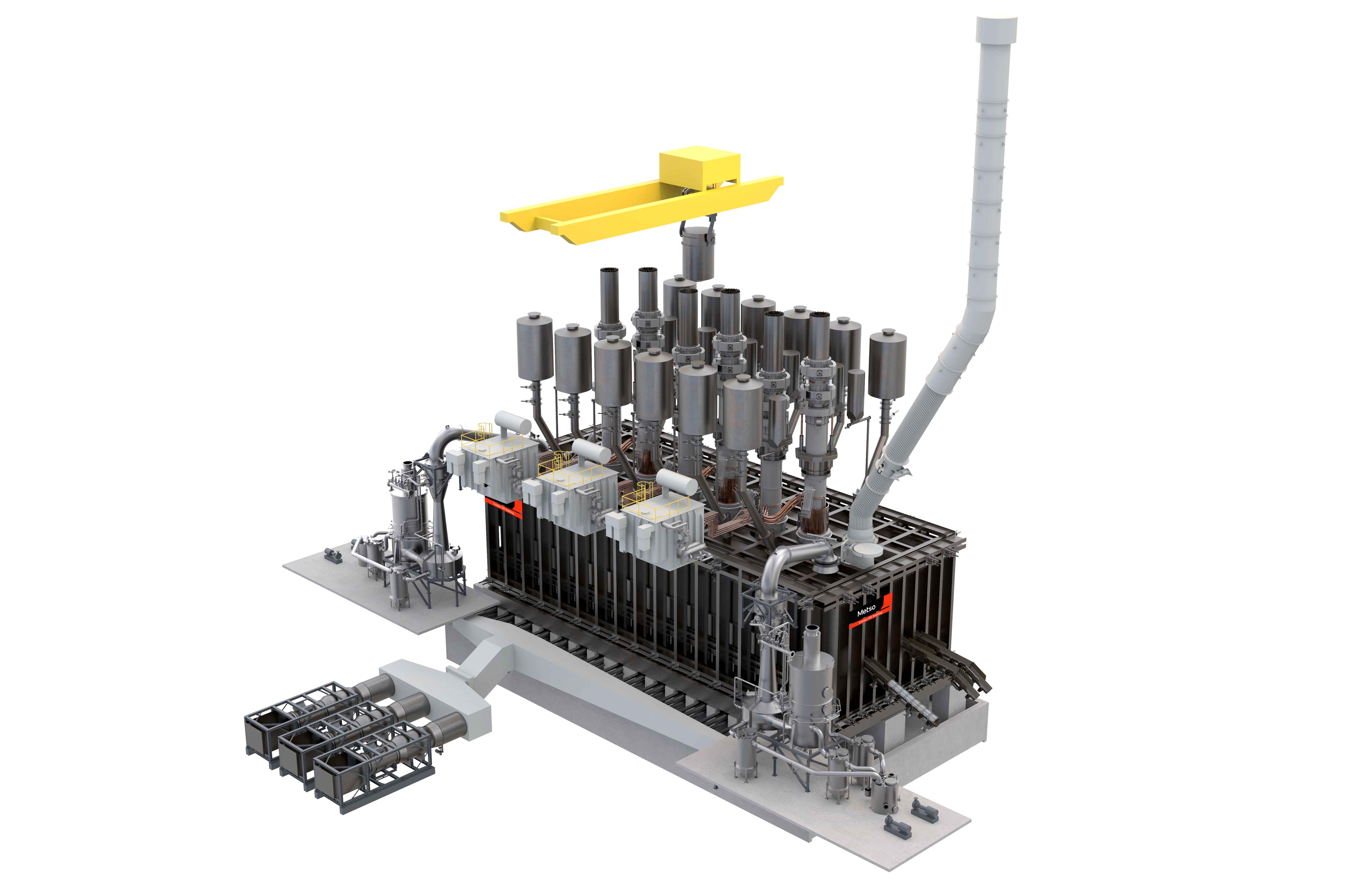

Pilot smelting furnace is designed for direct reduced iron (DRI) smelting, demonstrating equipment and process features of the large industrial scale Metso´s Outotec® DRI Smelting Furnace. It serves customers together with circular AC and DC electric furnaces located in Metso Research Center in Pori, Finland.

Since DRI properties are varying based on iron ore body and direct reduction technology used, piloting tests before industrial scale investment are very useful to validate simulation data and to verify the feasibility of the customer project. Differences can be seen for instance in DRI iron content, impurity contents, metallization rate and carbon content.

DRI pilot smelting furnace has three electrodes in line configuration. It is equipped with 2.5 MVA transformer allowing demonstration of DRI smelting in a scale of ~1 ton per hour. For typical one week test campaign about 50 tons of test material is required.

Details:

Metso’s Outotec DRI Smelting Furnace provides the following benefits: