HOW IT WORKS

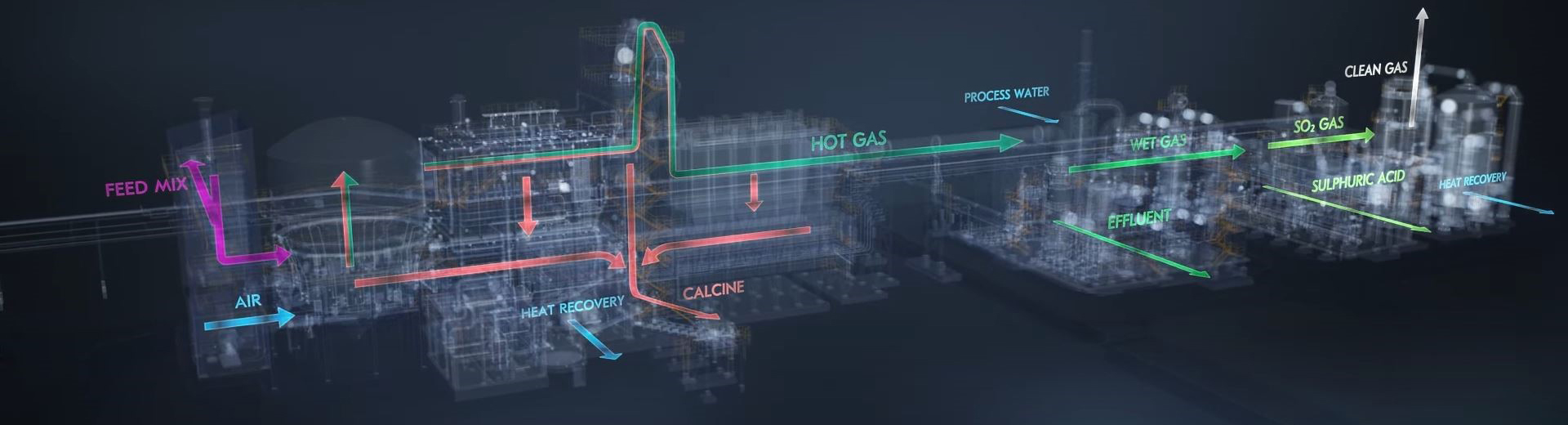

The optimizer performs real-time classification of load conditions to the WESP section based on the plant measurements. For applications with SO2, acid mist estimations are made based on automatic condensate measurements. Over time, plant-specific rates for SO2 to SO3 conversion are calculated and based on just the on-line measurements of gas flow and SO2 concentration, our digital tool not only optimizes the operation of the WESP section but also provides the operator with useful information on the overall performance of the upstream plant which may have led to those conditions.

Based on the load conditions, our optimizer will determine the optimal parameter setting on the T/R-unit. For plastic filters during low load conditions, to protect the material from damage, it strategically places a calculated voltage limitation on one or more WESPs to ensure material integrity. The voltage limitation is calculated to ensure that performance targets are still being met. Should a damage occur despite the precautions, the optimizer will quickly identify it and take action to flush the filter and take it out of operation to prevent further damage. During extremely high loads caused by upset plant conditions, the advisor adjusts the parameters again to keep the filters operating and maximize removal efficiency until the plant is back to normal operation.

In addition, the WESP optimizer assists plant staff with information on maintenance requirements. It monitors the flushing and – if applicable – fogging nozzles and water filters to provide information on when cleaning or replacement is necessary. It also quickly identifies and provides information on conditions that require operator attention.

IT-INFRASTRUCTURE

Metso WESP optimizer is installed in an industrial PC, which, either directly or through a separate PLC, is communicating with the plant DCS. As the function is merely advisory, the tool can be disconnected at any time, leaving the WESPs operating as normal, without any impact on their availability.

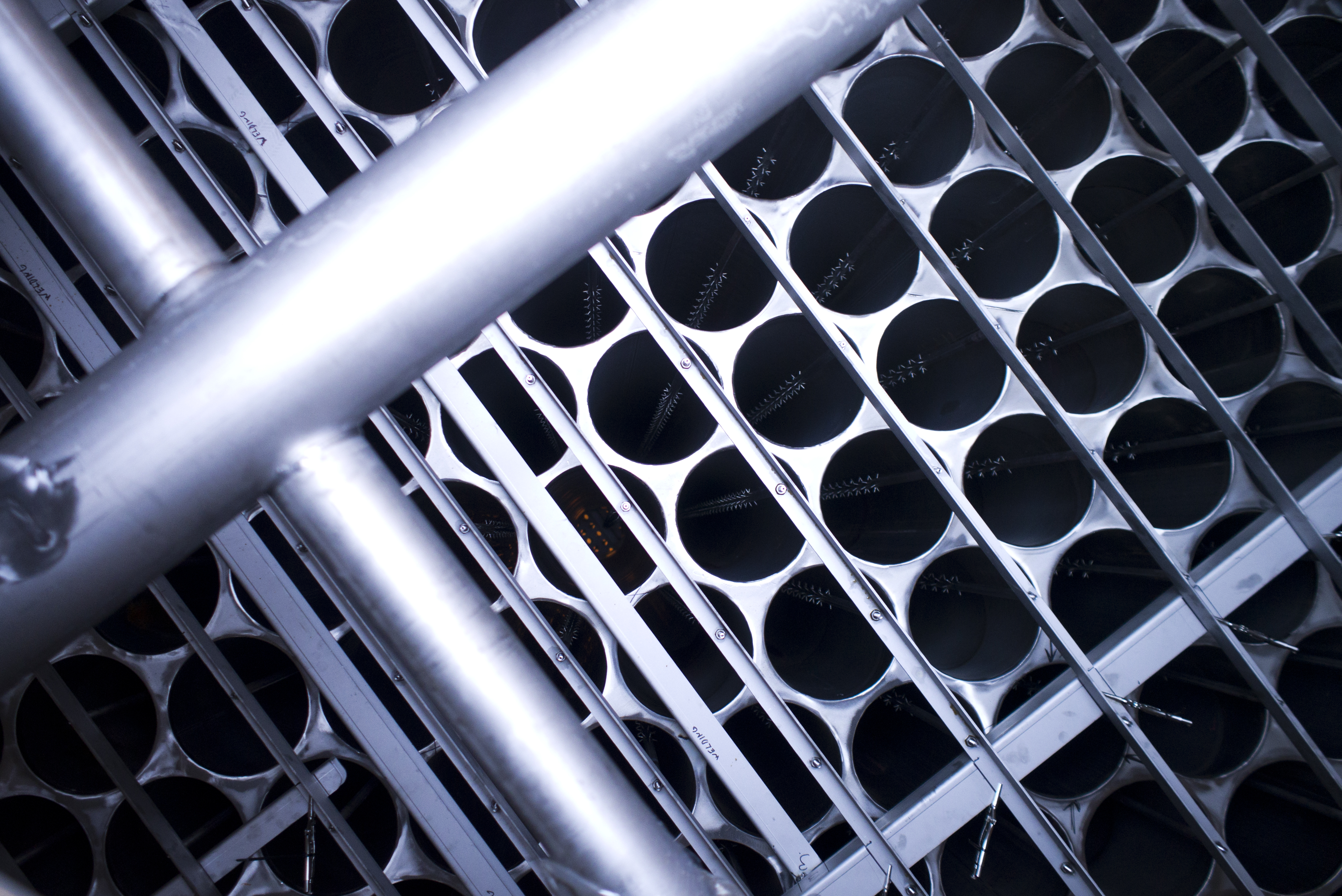

The optional separate PLC can also control the auxiliary water systems, flushing and fogging, of the WESP section in addition to supporting the advisor-DCS communication. The complete control option is performed by the Metso EDITUBE Control Cabinet (ECC), in which the PLC is situated. Using a well-proven and rigorously tested control system reduces the amount of automation design and plant down-time. The ECC has a touch panel with individual control of each EDITUBE and corresponding auxiliary equipment.

The optimizer has its own graphical interface in the ACT software. In addition, the optimizer offers a wide range of signals to be exchanged with the DCS which the client can use to create their own, tailored WESP optimizer view withing the existing plant DCS.