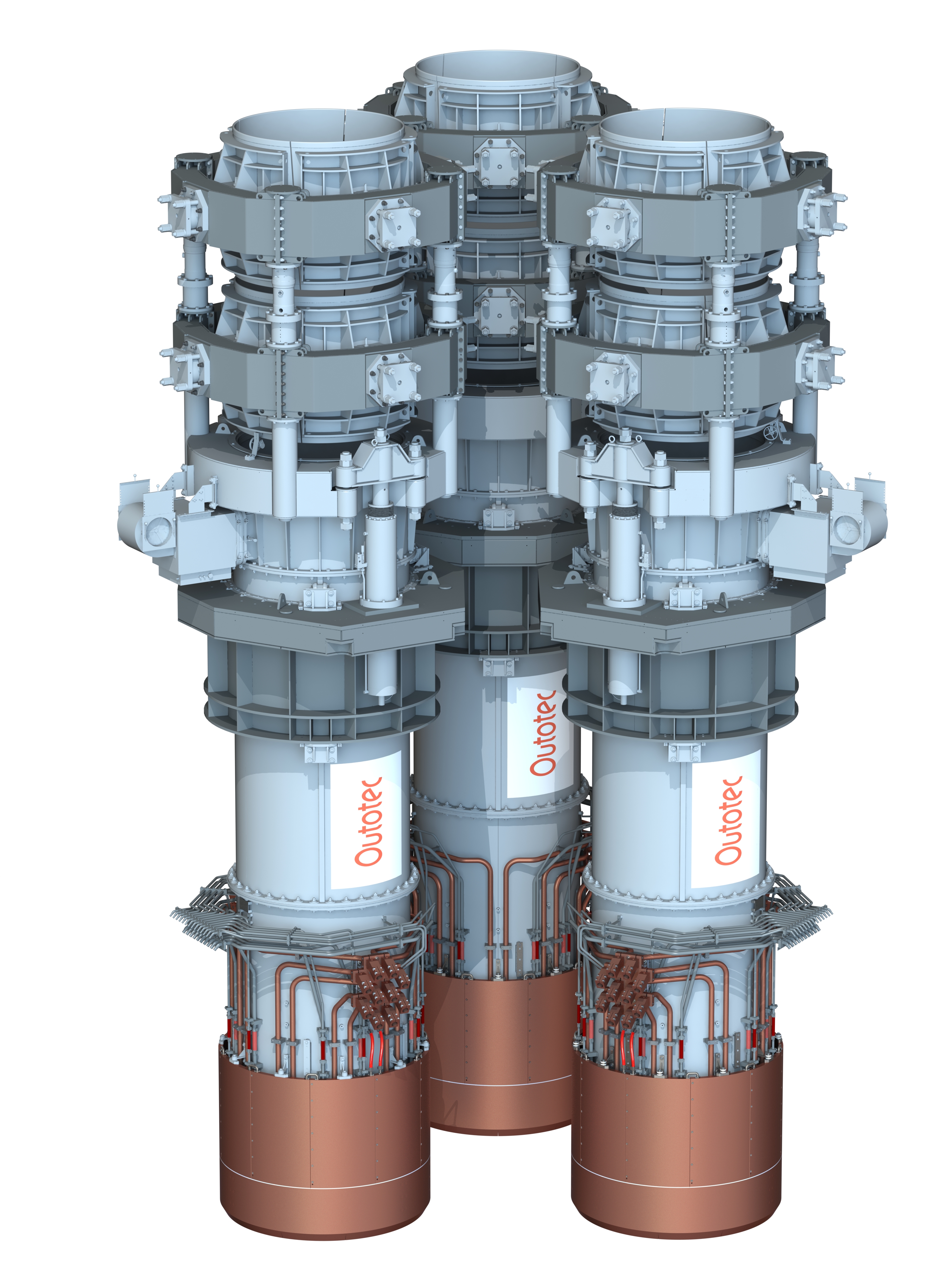

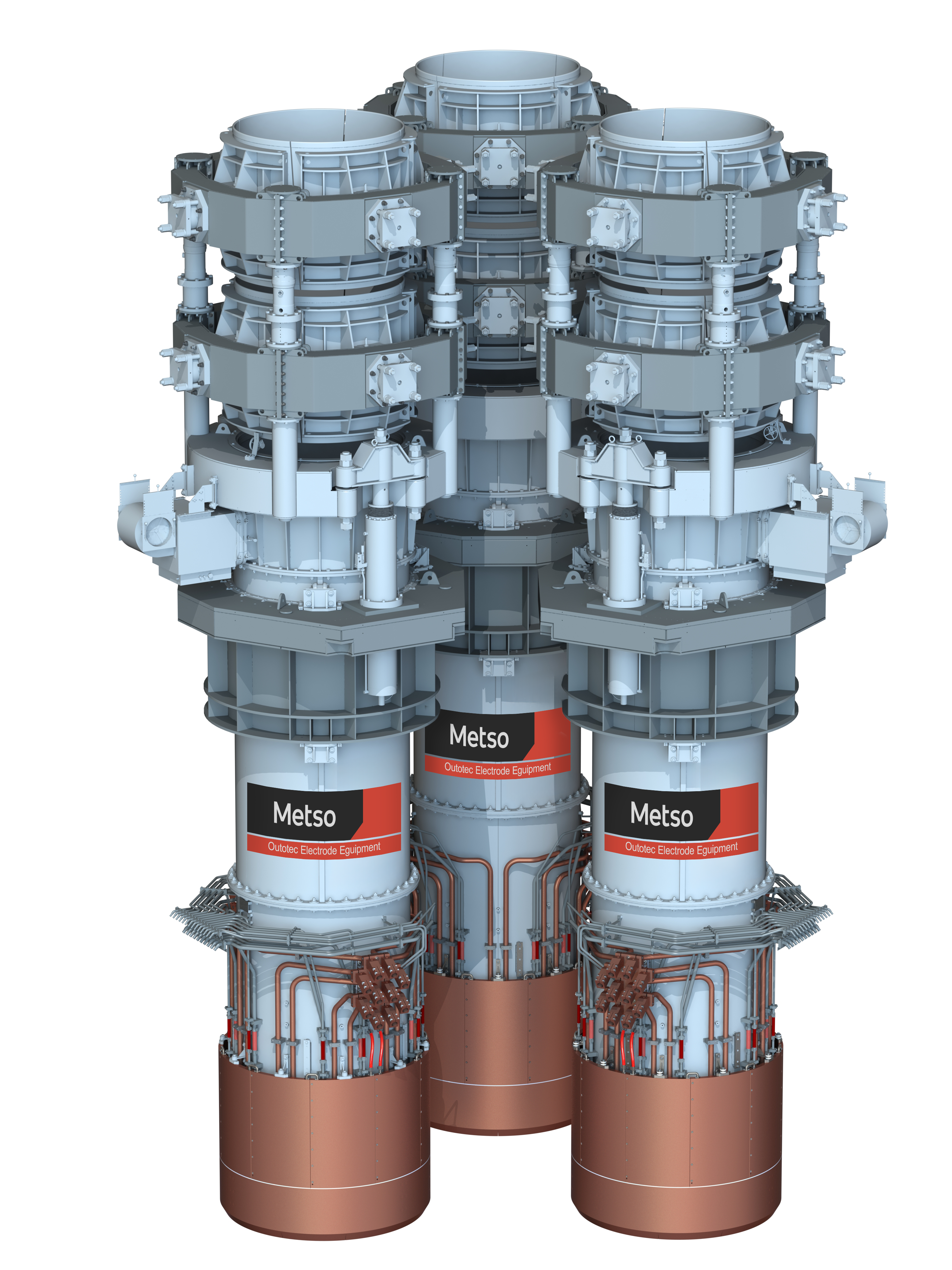

Metso offers electrode equipment for all types of electrical smelting and slag cleaning furnaces, both direct current (DC) and alternating current (AC), for the processing of, for example, ferrochrome, ferromanganese, ferronickel, copper, and nickel. Ferroalloy AC furnaces are typically operated with Söderberg-type electrodes. Slag cleaning furnaces can be operated with Söderberg or graphite/carbon electrodes. For silicon metal furnaces, Metso has a compound electrode, and for small silicon metal furnaces we offer a carbon electrode. Metso offers both greenfield and brownfield deliveries, including upgrades of existing electrode equipment.

At Metso, safety is our first priority in equipment design. Our operating principles and control systems are designed to minimize the need to spend time in hazardous areas. The fail-safe principle is used to minimize damages from any failure. For example, the fail-safe spring clamping system is used in the slipping device to prevent accidents during a power failure or loss of hydraulic power. High availability is guaranteed by our equipment design as well as component and material selections. All critical components are designed to be maintenance free during normal operation. To shorten downtime after abnormal operating conditions, all critical parts are designed for easy replacement.

Energy efficiency is guaranteed by using high-purity copper in the lower part of the electrode equipment. All materials are selected to ensure longer equipment lifetime and minimize eddy-current losses.

All main components of the Metso's Outotec electrode equipment are developed, owned, and patented by Outotec. This enables seamless integration of the equipment and enables a high level of customization according to your needs. The quality of our equipment is assured as we manufacture all critical components in our own workshop in Finland. Before delivery, the Factory Acceptance Test is performed for fully assembled equipment in the machinery shop to guarantee easy assembly on site and to enable the smooth ramp-up of the plant.