Smelting Newsletter

Includes case studies and customer experiences from around the world in technology innovations, market information, new products & so much more.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

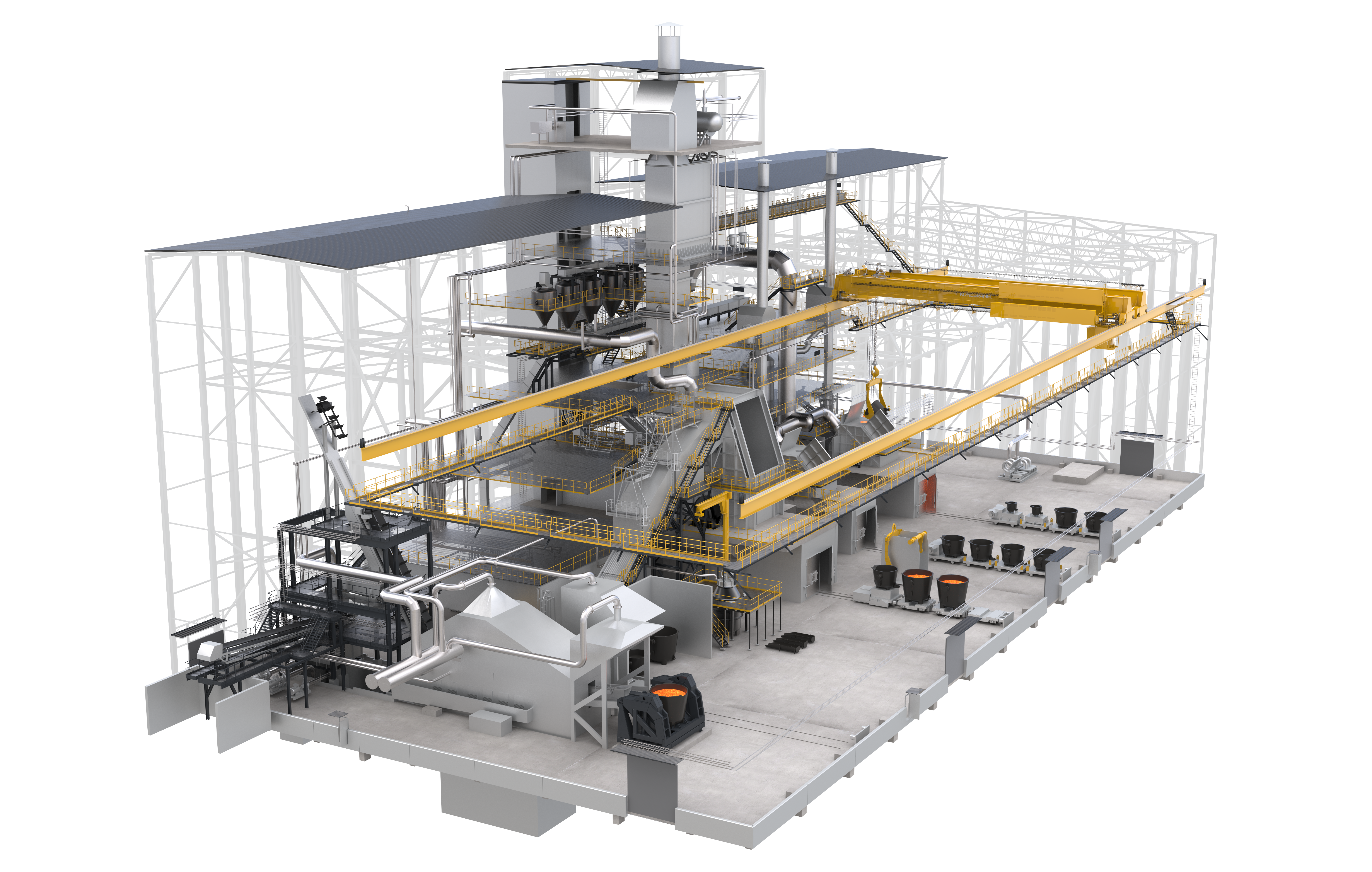

We can provide complete process solutions to solve any smelting challenge, covering every step from raw material through to final product. Metso's Outotec eScrap solutions comply with the strictest environmental regulations and can be supported with pilot testing, process guarantees and advisory services. By helping to turn waste into valuable metals, our solutions help to take advantage of the exciting new opportunities being created now for the circular economy of the future.

The Metso eScrap solutions offering comprises the following products:

Electric Slag Cleaning Furnace