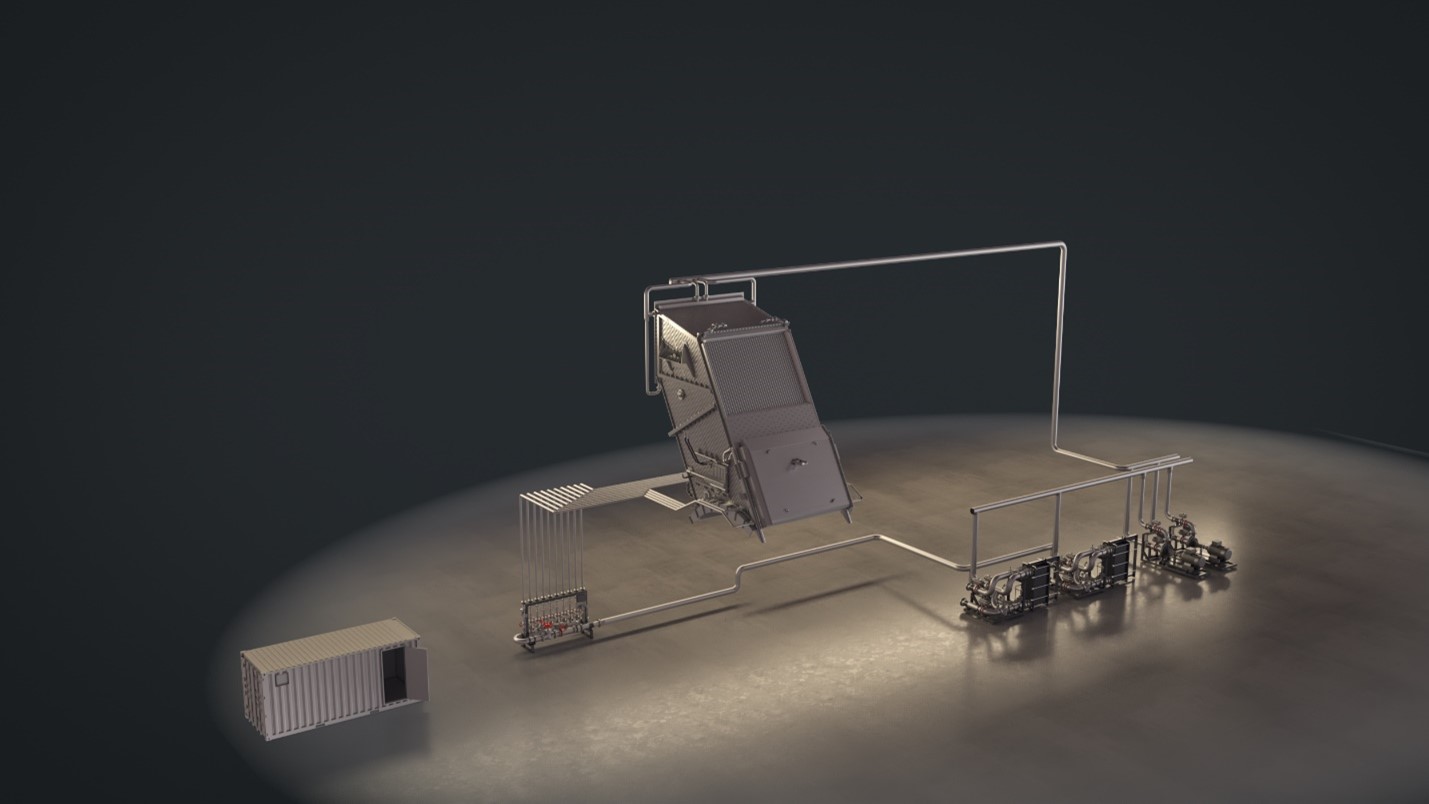

Controllable outlet temperature coupled with advanced model-based automatic control for start-up and varying process conditions

The even temperature profile reduces the risk of condensation, protecting the tower and downstream equipment from corrosion

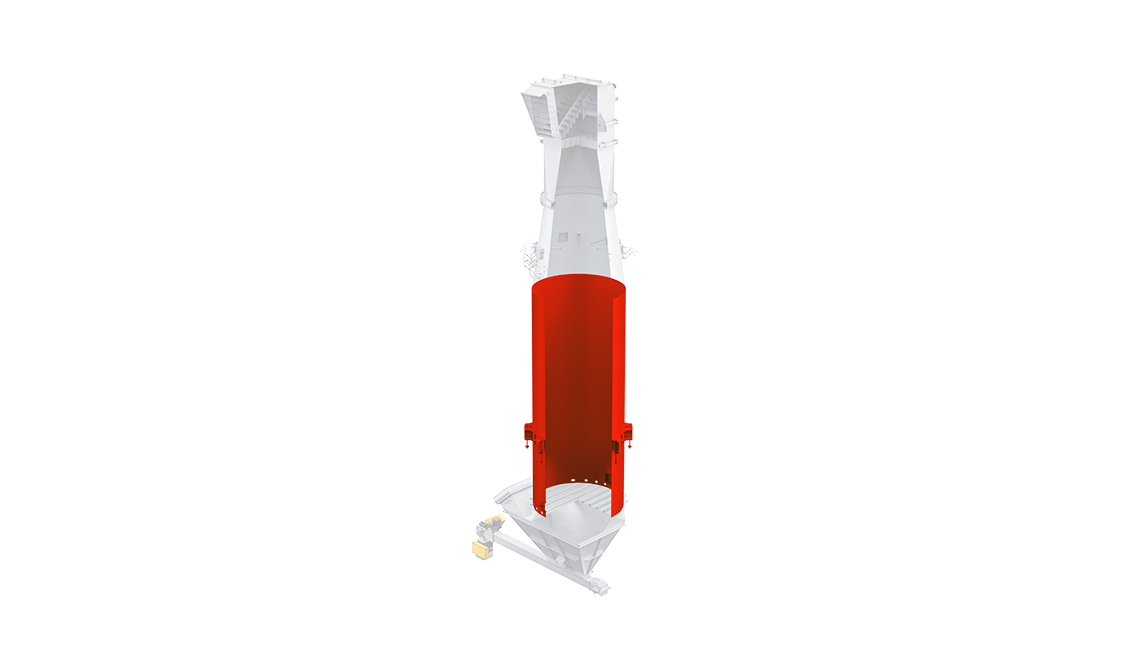

Two media nozzles which produce small droplets that are evaporated quickly. Guiding vanes and nozzles for even gas distribution and cooling

A large turn-down ratio and lower air consumption can be achieved in the tower design through the selection of nozzles and number of headers

The Evaporative Cooling Tower is typically manufactured from stainless steel to withstand both the temperature and the gas content. The gas cooling effect comes from evaporation of water sprayed into the tower through nozzles, where the water is atomized to tiny droplets with compressed air. The Evaporative Cooling Tower operates dry, meaning that all droplets are evaporated before they reach the bottom of the tower. The spray water flow is controlled in relation to the gas temperature at the cooling tower outlet.