Metso Feeding Solutions has over 125 years of experience with over 3,000 installations globally. With this industry leading expertise, experience and technology, Metso has now developed the latest addition to the portfolio: the Crossover™ feeder.

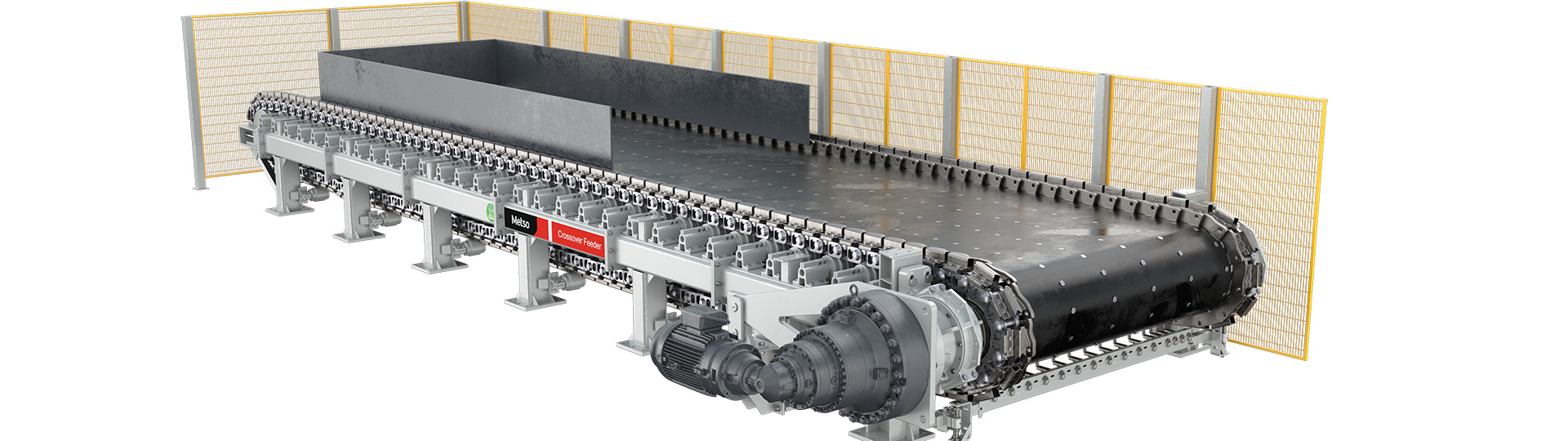

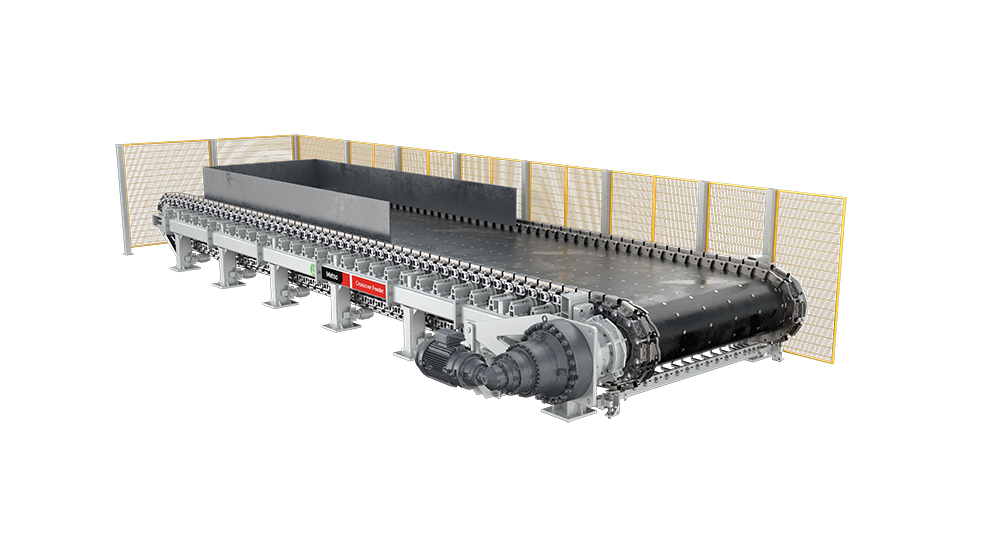

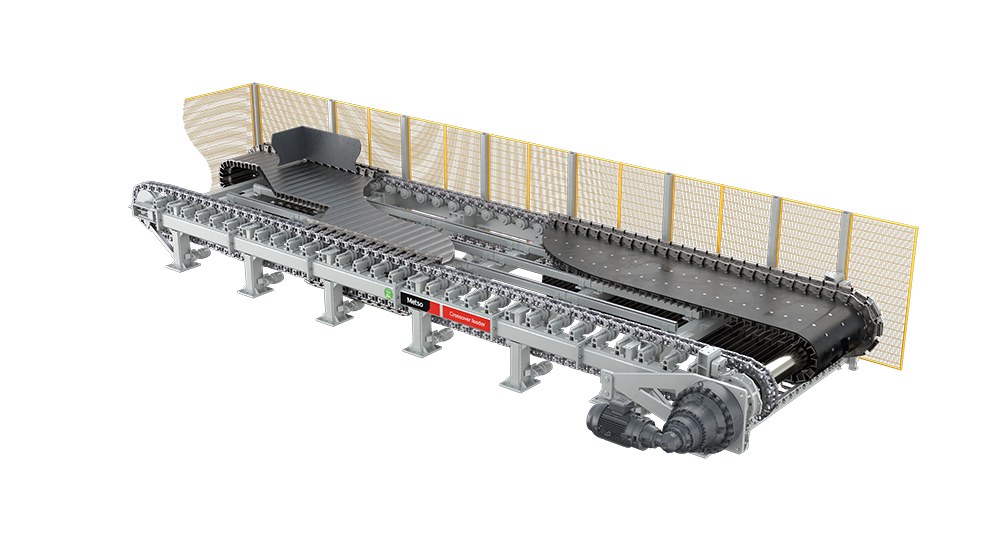

Metso's Crossover™ feeder combines proven designs with innovation and modularity to produce a belt-over-apron hybrid solution. The Crossover feeder provides an alternative solution to applications where an apron or belt feeder would not be the optimal choice.

Flexibility

The Metso Crossover™ feeder has a unique design that uses modular components to configure any size of feeder that would be required. This approach creates a quicker execution process overall and more availability for the feeder.

Also the Crossver™ feeder gives a height reduction compared to conventional feeding technology. This allows the feeder to fit in applications where there are height restrictions, but also provide easy replacement capabilities in the right brownfield applications.

CAPEX savings

Metso's Crossover™ feeder is designed to boost cost efficiency compared to conventional feeding technology. Through the reduced design height, less excavation and civil work will be required and results in providing installation cost savings.

With a modular design and bolt construction, the Crossover™ feeder provides an efficient solution for brownfield replacements of existing apron or belt feeders where access is limited.

Lower OPEX

Like Metso apron feeders, the Crossover™ feeder features robust, sealed for life track components. These provide long and reliable operating life.

Also to mention that since the Crossover™ feeder does not require a dribble belt, requires less rotating components and less maintenance. All of this combines to result in less operating costs.