The flexibility of Metso's Outotec DC furnace opens up opportunities for exploiting reserves that would have been considered economically unattractive using conventional smelting technology. Typical applications include fine chromites, ilmenite, low-grade laterites, and dust generated during steel production, especially stainless steel.

One of the biggest benefits of DC smelting technology lies in recycling applications. It can be used to process and recover valuable metals from materials such as the dust resulting from the production of steel and other metals. Traditionally these materials would have ended up in landfill, but with Metso's Outotec DC smelting they can be processed without any agglomeration.

Metso's Outotec DC smelting is suitable for a wide range of commodities and applications, including:

- Ilmenites (Ti) and titaniferous magnetites (Ti, V)

- Chromites (Cr)

- Laterites (Ni)

- Steel-plant dusts (Ni, Co, Cr)

- Slag cleaning (Co, Cu, Ni, V)

- Blast furnace slag (Pb and Zn fuming and condensing)

- Platinum group metal smelting (including Pt and Pd)

- Dolomites and magnesites (Mg)

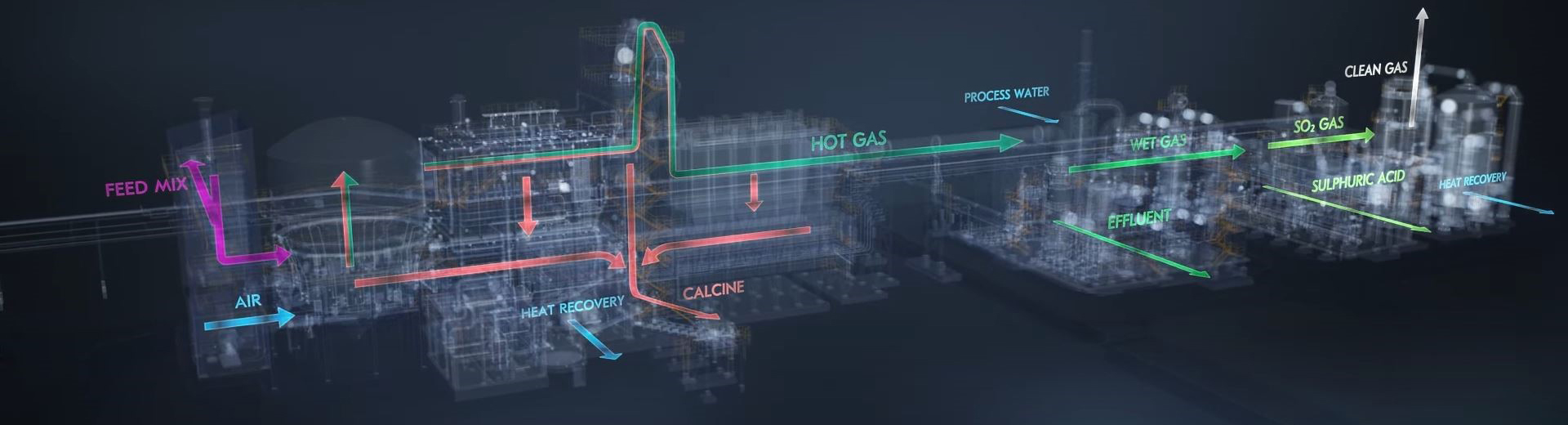

Metso's Outotec DC smelting can be combined, for example, with the Metso's Outotec ferrochrome process to enable efficient treatment of all side streams.

Metso's Outotec DC smelting can also be combined with Metso's Outotec rotary kiln for energy-efficient ilmenite smelting, or Metso circulating fluidized bed (CFB) technology as part of the modified Metso circonickel process for laterite smelting.