Reaching your sustainability targets?

Find out how our filtration services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Membranes adhere to strict quality controls in both dimensions & material structure

Optimal lifetime ensures filter reliability

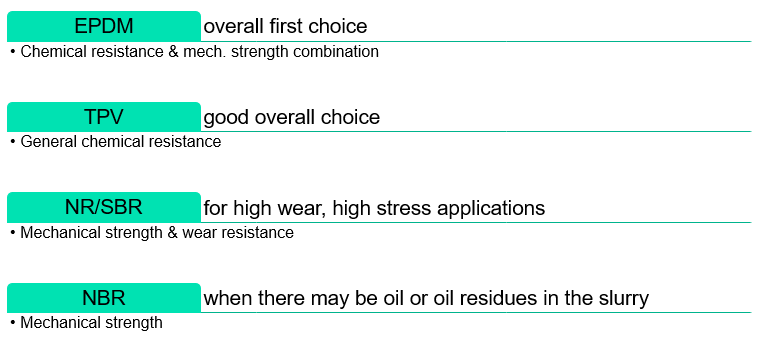

Various materials to suite your process and application

Suitable for all mining and metals applications, as well as Chemical Process Industries

Filtration membranes are essential for transferring pressure to the slurry for effective dewatering, where water that is not adsorbed by solid particle surfaces is drained from the plate chamber.

Membranes are made from polymers that operate under constant strain due to the stretching and contraction after every filtration cycle and therefore require frequent replacements.

Membranes should adhere to strict quality controls in both dimensions and material structure, to ensure reliability which offers an optimal lifetime. Higher quality membranes also minimize unexpected membrane failures (such as leaks affecting cake moisture quality) and costly unplanned shutdowns for membrane replacements that impact production.

The frequency of replacement is dependent on process-specific conditions and will vary between various customer applications. It essential to inform customers to start collecting field data regarding membrane lifetime. The data collected can then be analyzed to assist our customers to find the best PM policy for membranes.