Time savings

Reduced delivery and erection time

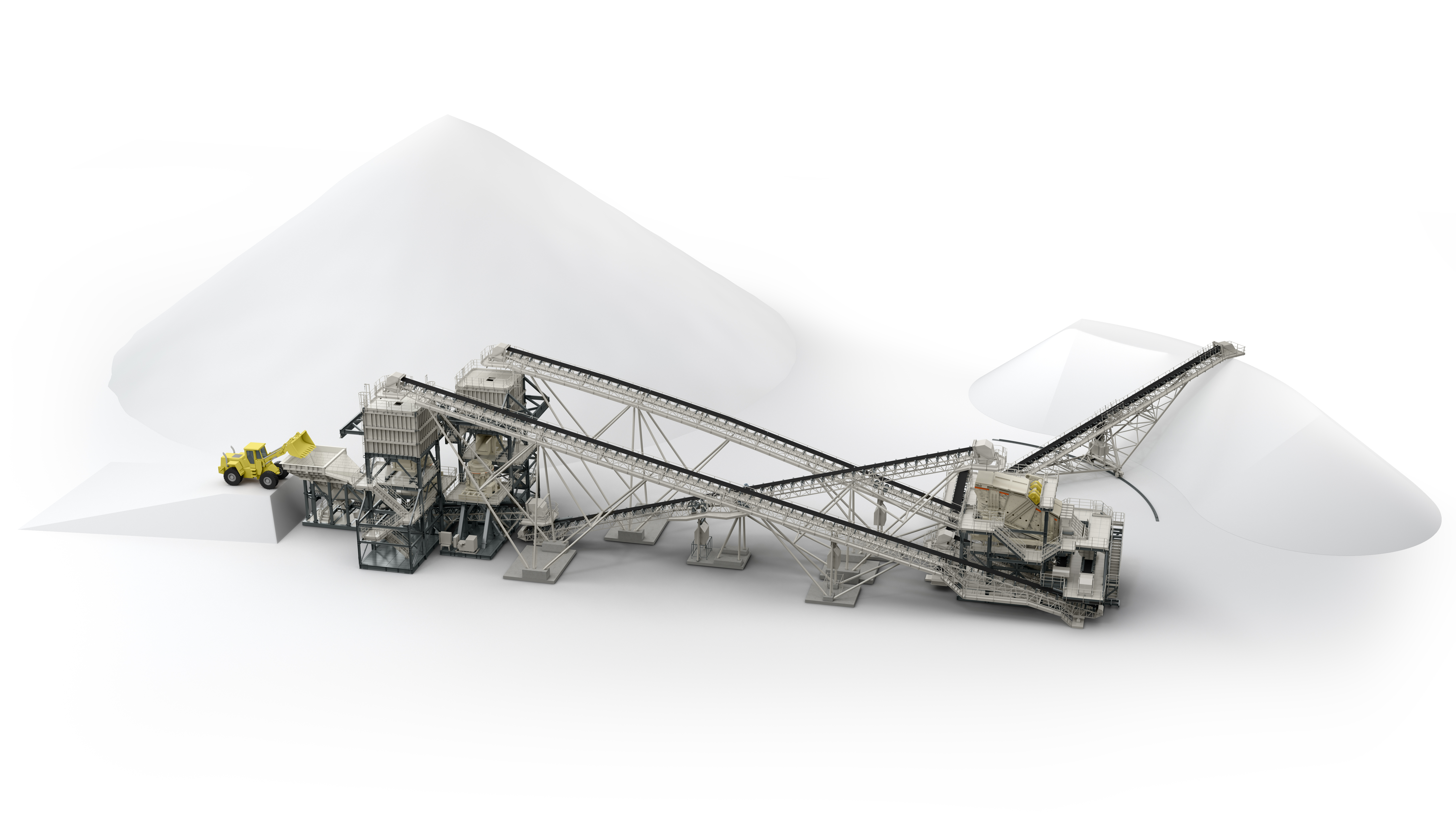

Multiple station configurations

Modular equipment configurations available

Flexible

Wide range of solutions for many applications

Capacity

Capacities ranging from 200 to 3,000 tons per hour

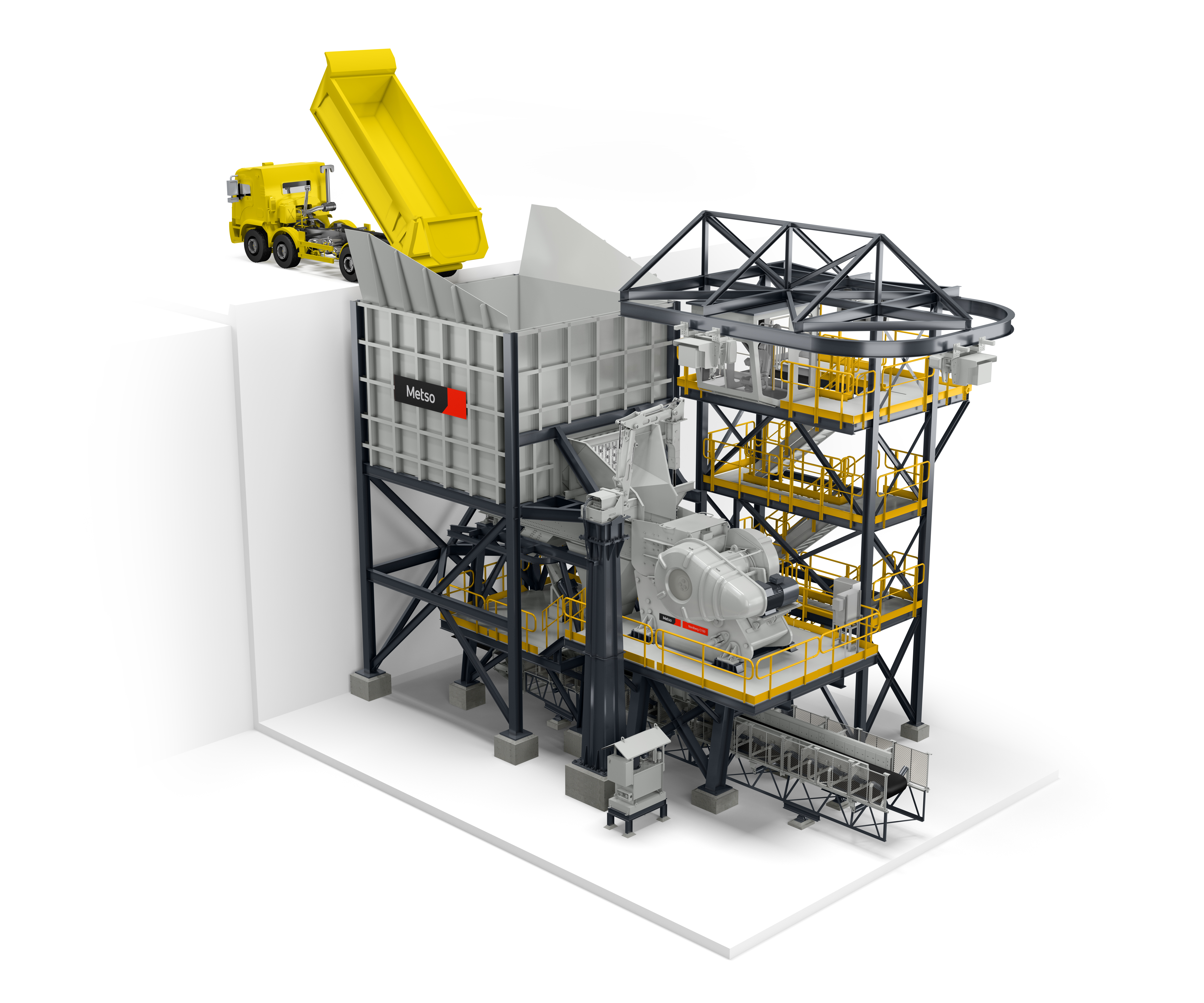

FIT™ Stations - Find your FIT

The primary gyratory stations have 3 unique configurations based on the application: Single feed, Dual feed and Indirect feed. The primary gyratory stations also allow up to a 4,000 tons per hour capacity.

The PG station utilizes our unmatched Superior™ MKIII PG crusher. Models that are included in the scope are the 42-65, 50-65 and 54-75. The station also would be paired with a hopper, bin and a feeder.

The flexibility also comes from the ability to be either stationary or skid mounted.

The Jaw stations has over 30 possible configurations, 25 weeks of lead time (FCA) and capacities up to 3,000 tons per hour. With the modular design this also allows for ease of maintenance.

The Jaw stations utilize the proven performance of the Nordberg® C120, C130, C150 or C160 jaw crushers. The configurations also involving our grizzly and apron feeders and grizzly scalpers.

There is also flexibility not only for the equipment selection, but also these stations can be designed as a stationary plant or skid mounted for some mobility.

Recrushing stations are best applied in secondary or tertiary stockpile recrushing applications. The Recrushing stations can handle capacities up to 750 tons per hour and have a lead time of 25 weeks.

Recrushing stations involve the historic HP Series™ cone crushers, specifically our HP400 and HP500 models. Conveyors are also included as part of the solution, and the station is also skid mounted.

Our Recrushing stations when placed as a supplementary plant for reprocessing plants will increase SAG mill capacity by up to 15%.