Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

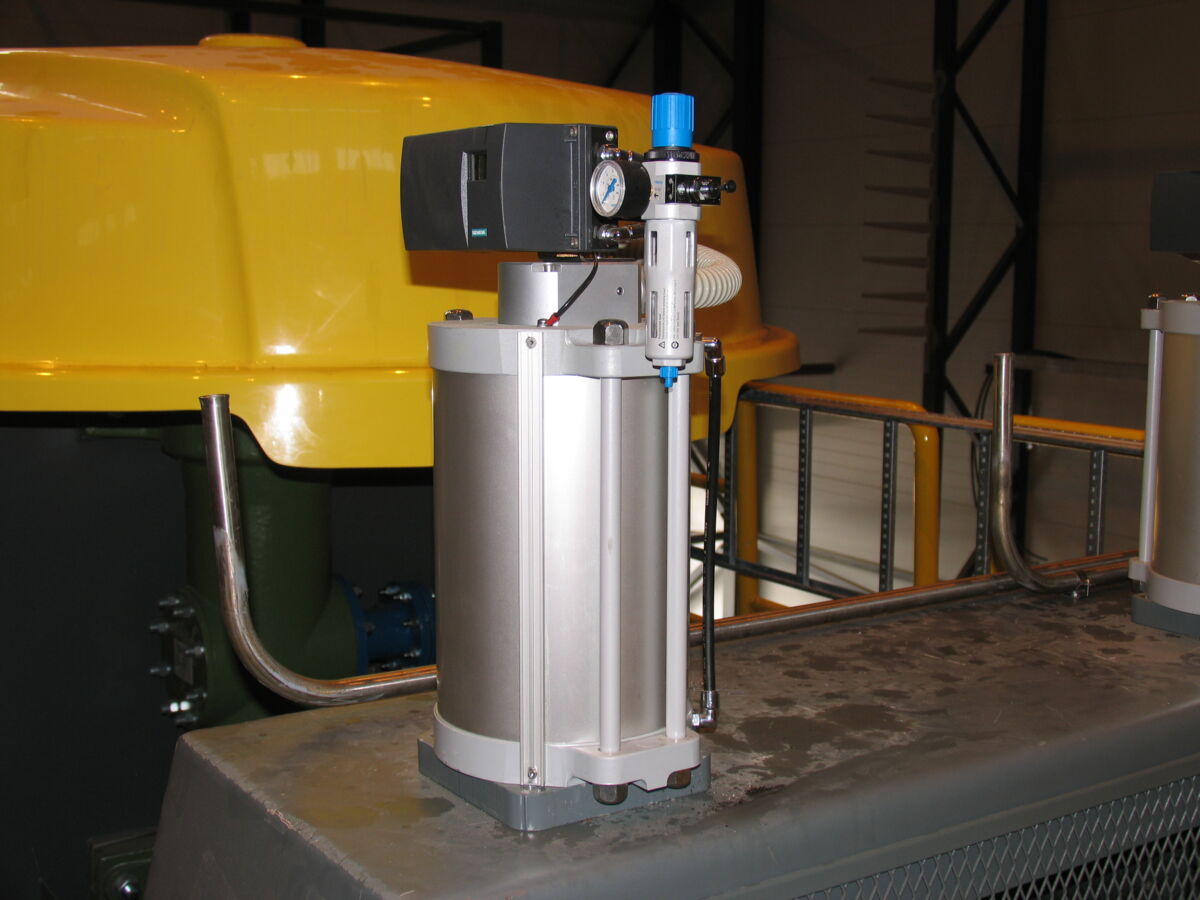

Automatic valve position measurements with fail-safe function

Correct sizing improves response leading accurate level control

Longer wear life with the correct range of stroke

Proven to offer the longest wear life of all known dart valve arrangements

Optimized flow control – Provides precise slurry flow regulation, improving process efficiency.

Extended wear life – Built with high-quality wear-resistant materials, reducing maintenance frequency.

Reduced downtime – Durable components ensure longer operation cycles with minimal interruptions.

Improved process stability – Helps maintain consistent operating conditions in flotation circuits.

Low maintenance design – Designed for easy servicing and component replacement.

Heavy-duty construction – Built to withstand harsh mining environments.

High-precision control – Advanced design ensures accurate flow modulation.

Corrosion & abrasion-resistant – Manufactured with superior materials for extended durability.

Customizable options – Available in multiple sizes and configurations to meet site-specific requirements.

Easy installation & integration – Compatible with existing systems, ensuring seamless upgrades.

Accurate and reliable level control is one of the key operating variables in flotation. Especially in big cells, every minute of lost concentrate mass pull is worth a considerable amount of money. Changing process conditions and low availability may lead to requirements for improving level control arrangements and design.

Performance, availability and low running costs are the main design criteria of the improved dart valve level control arrangement. Dart valves are suitable for Metso TankCell, OK-cell, and similar flotation machines.

Smooth froth flow rate is one of the key factors affecting froth recovery and has a positive influence on overall metallurgical performance. Accurate and responsive level control is vital to ensure this. Properly sized steep-angle plugs need to be matched with a long-stroke actuator. The length of the stroke is a key element contributing to accurate level control. Furthermore, with correct sizing, the response to the control input is practically linear.

The new actuator unit measures the valve position accurately by using intelligent piston positioners. In the old design, the position was measured mechanically from the outside, which lead to a situation where construction got easily mechanical damage. The actuator unit reliability has been improved by designing an articulated joint that removes tensions directed at the unit. The improved actuator unit also includes a fail-safe function as an option for scenarios when the loss of air pressure or electricity occurs. The fail-safe function allows the operator to operate dart valves manually twice after an electrical or pneumatic malfunction.

The key design criteria is to maximize the wear life of the level control components. The Inside Dart with open design has proven to offer the longest wear life of all known dart valve arrangements. An open tank area around the inlet and a wide intermediate channel after the socket are essential. They guarantee the lowest possible flow rates from cell to cell without the risk of sanding. Laminar flow and moderate velocity are the key factors contributing to long wear life. A properly selected range of stroke is another important factor determining wear. If the stroke in typical conditions is too short, i.e. the valve operates near the closed position, the flow rate will be high, thus inducing wear.

A dart valve upgrade consists of a dart valve socket, plugs, a rod, and an actuator unit. Depending on the requirements only some of the scope can be applied.

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice