Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

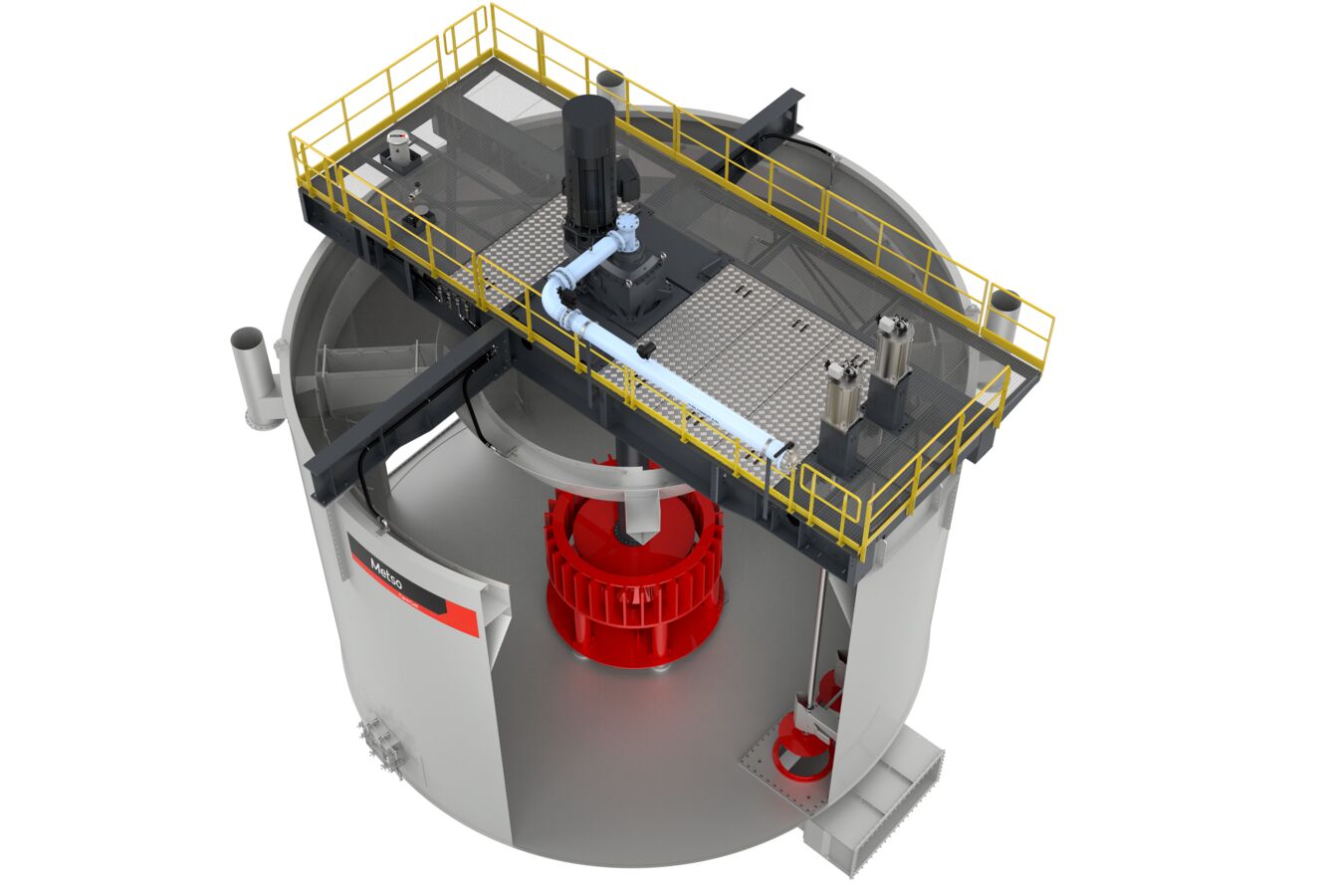

Increased froth collection

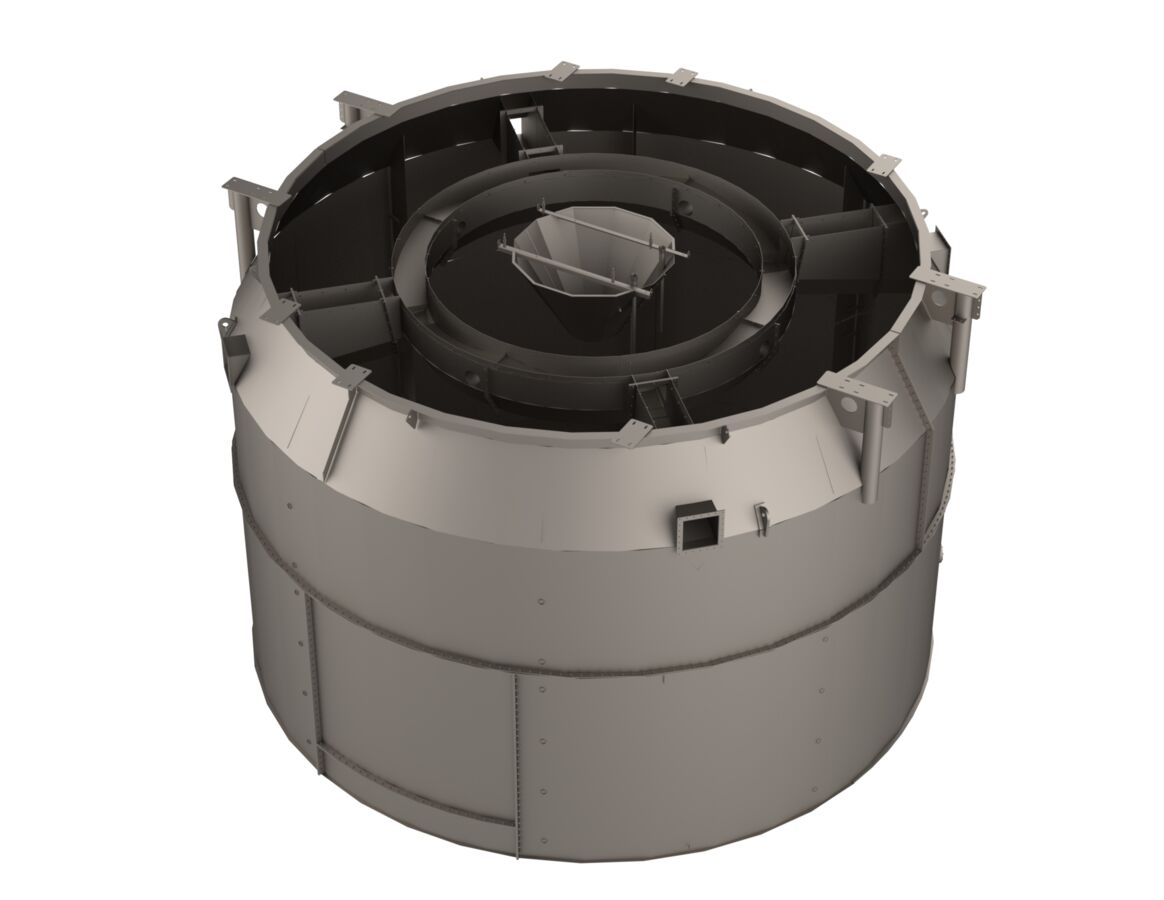

Upgrade existing cells with a launder configuration

Recover more valuable material & reduce loss to tailings

QUESTION |

ANSWER |

| Can Metso design a new launder configuration, and how is this done? | Our experts can design a new launder configuration based on your current process performance. The mass pull and froth carry rate is used to calculate the optimal lip length and froth area for the specific cell duty. There is an assessment to identify current FCR and lip loading. |

| Can different launder designs be combined? | Different designs can be combined in order to achieve the optimal lip length and froth area. For example, this can be done by combining radial and external peripheral launders. |

| Does the upgrade require the cell bridge to be strengthened? | Changing the launder setup does not require any structural changes to the flotation cell. |

| Does Metso check that all lips are at the same height in order to ensure that the speed of froth crossing the lip is equal throughout the cell? | All lip heights are adjustable, and we can check the lip heights as a standard part of our installation process. |

| What impact can incorrect froth area and lip length have on the froth speed measured by Metso FrothSense™? | The froth speed is highly dependent on the froth area and lip length. If either of these is incorrectly designed for the cell duty it may result in the froth speed being too fast or too slow, making froth speed control extremely challenging. |

This service is available for both Metso and other brand flotation machines. It includes: