Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

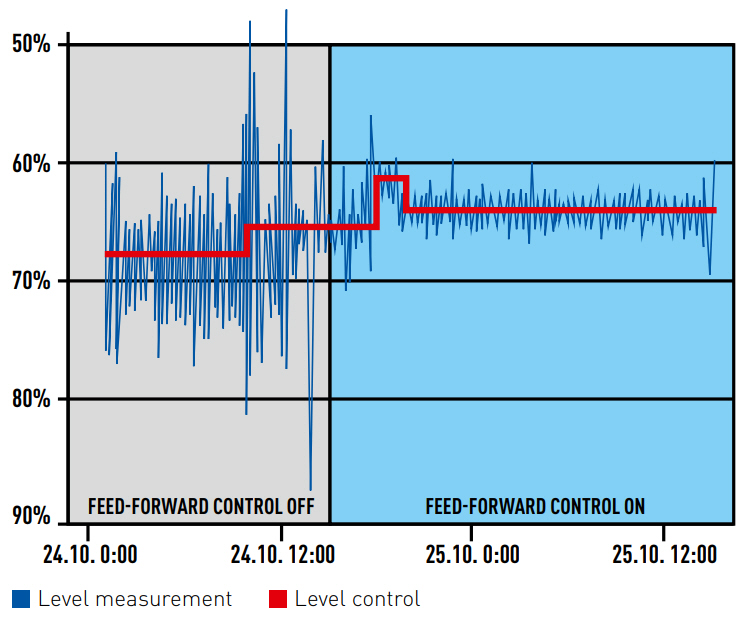

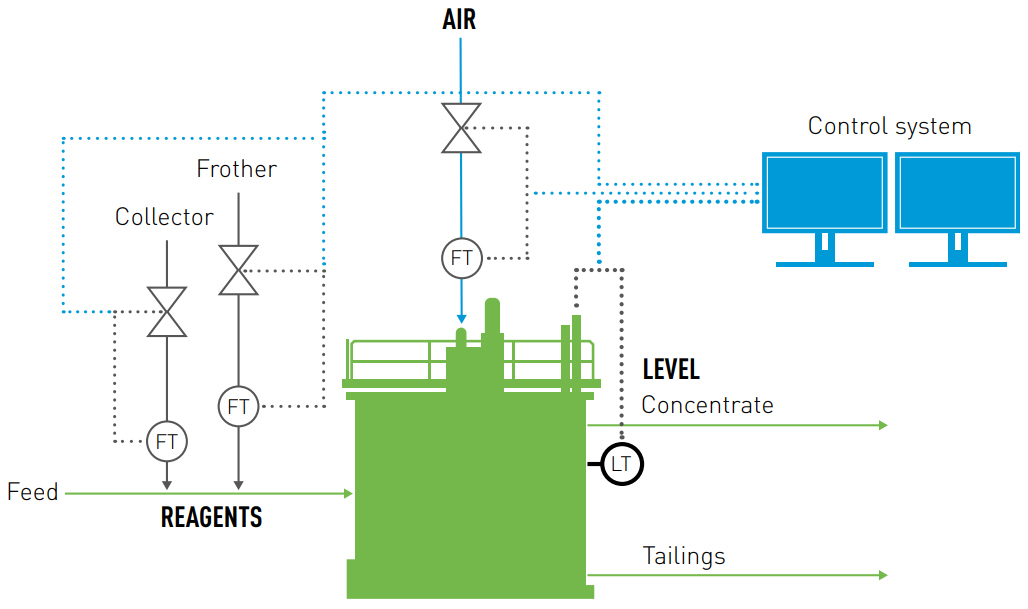

With accurate, reliable level control

Tailor-made solutions that to increase metallurgical performance

Flexible to capacity changes

With electro-pneumatic dart valves & long-stoke actuators

QUESTION |

ANSWER |

| When should I consider upgrading my level control system? | You should consider upgrading if you want to switch from manual to automatic control, or if you don’t typically operate with a valve opening of between 20 and 70%. |

| Is there a reliable way to measure froth bed thickness? | Metso LevelSense – our proven, low-maintenance solution – is the best available technology for slurry-froth measurement. |

| Is it possible to use my existing level-control components in combination with the upgraded ones from Metso? | Providing your existing components are compatible and meet the required standards for accurate level control, they can be used alongside the upgraded components. |

| Will I need to replace the actuator if the volumetric flow through the dart will be larger or smaller? | The actuator may need to be replaced with a larger or smaller unit, but Metso specialists will first check whether the existing unit is capable of handling the new volumetric flow and dart stress. |

| Are there any special requirements if multiple cells in the same level step are controlled by two valves? |

We always recommend using cells in a single step, as this optimizes metallurgical control. For plants where multiple cells are in the same level step, we will design the dart-valve upgrade accordingly.

|