We start the optimization process by understanding your process goals. Our flotation experts can measure characteristics such as bubble size, bubble load, superficial gas rate (Jg), froth stability/transportation/depth to identify possible avenues for improving flotation cell performance.

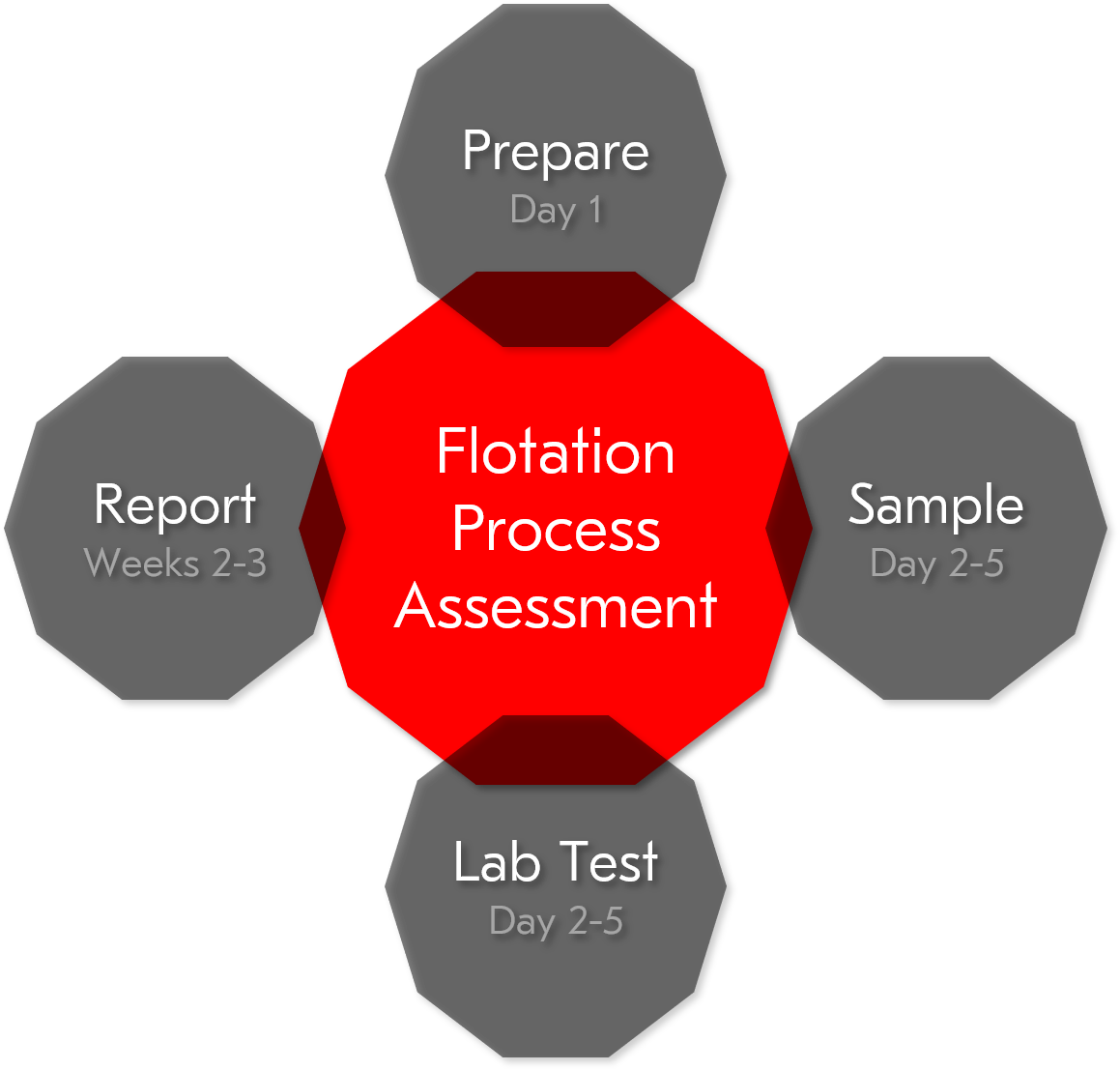

The purpose of the Flotation Process Assessment is to gather in-depth information on the process that is not available from the automation systems or from the daily sampling to manage the information by looking for tailor-made solutions.

This information, along with detailed surveys and historical operating data are used in modeling and simulation techniques. These techniques, together with extensive industrial and consulting experience and database are used to evaluate existing or new operations, and highlight opportunities for improvement in performance.

Our Flotation Process Assessment covers the main disciplines of debottlenecking the flotation performance and can be tailored to focus on certain disciplines or all of them. Ideally, the assessment is conducted by selecting the most important information for future decision-making. This service includes extensive site work as well as a deep back-office data analysis.

The models can also be used to evaluate disturbances to the circuit tonnage, changing the feed ore type or changing the reagent addition rates to the circuit. Once an improvement area is identified, we work with you on the design and implementation of the proposed changes.

The performance of the flotation circuit is often strongly influenced by feed size from comminution circuits. Metso experts can determine the relationship between grind size and the flotation grade-recovery performance for your operation and determine the optimum trade-off between grind size and flotation recovery.

In flotation operations, the metallurgical team follows the daily production and is equipped to respond to any changes in the process to maintain concentrate quality at the specified level and maximize recovery.

Common questions during daily operations are:

- “What are today’s recoveries and grades?”

- “Are the mills running with maximal throughput?”

- “Are we within the budget?”

Questions that are often overlooked:

- “What could be the recovery?”

- “Where are we losing valuable minerals?”

- “Is the equipment operating at its best?”