Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Efficient process controls use less raw material and energy

Less human intervention and manual work

A flexible process that can cope with ore changes

Reduced process disturbances & fluctuations improves metallurgical performance

In order to maintain profitability in the face of challenging commodity prices, it is imperative to improve the efficiency of your existing assets. This means ensuring smooth plant operation, developing a flexible process that can cope with ore changes, maintaining equipment reliability, and minimizing start-up losses. Furthermore, high personnel turnover can make it challenging to retain core skills and competencies in your operation. Many sites also face challenges with the high cost of consumables and the increasing demand for more comprehensive production reports.

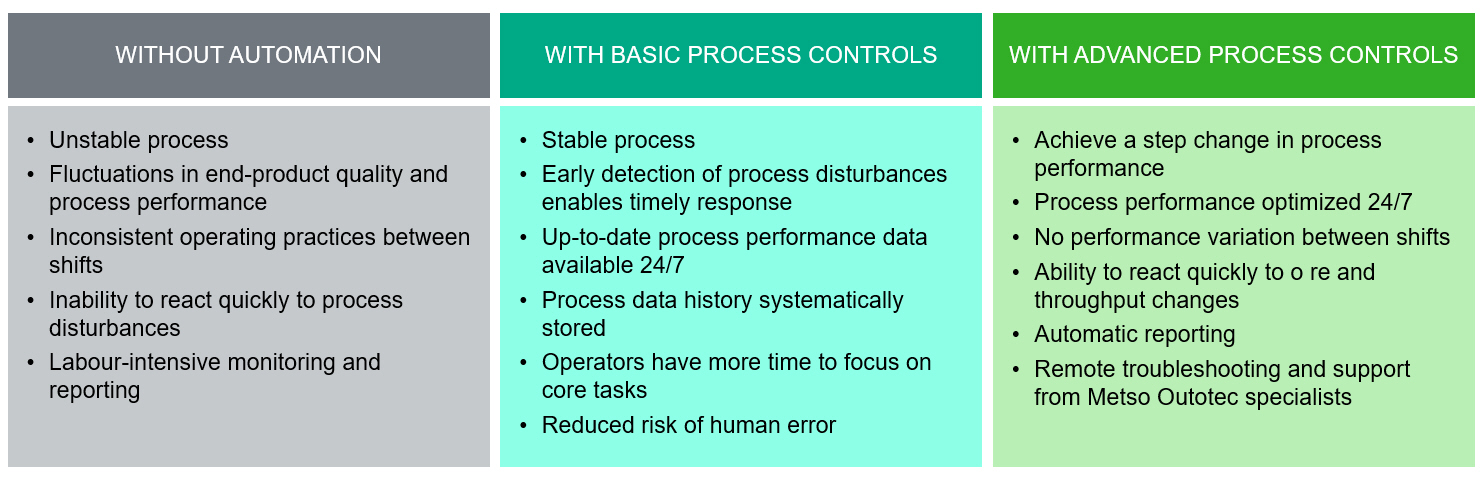

Effective, automated, and integrated control can help to solve all of these challenges, while also minimizing the risk of production disturbances and downtime, and supporting compliance with strict health, safety, and environmental standards. It provides you with tools to identify disturbances and stabilize your process, and also get a clear overview of your production.

We have a proven track record in metallurgical process automation that stretches back over 30 years, and our flexible solutions focus in particular on ease of use, practicality, and component compatibility. Put simply, they are designed to secure maximum production performance for your specific application.

We can help you automate brownfield operations cost-efficiently and with minimal downtime through a holistic but modular approach that covers all levels of automation and services for all concentrator processes. A higher level of automation reduces process disturbances and fluctuations, resulting in increased capacity and improved metallurgical performance.

The following basic set of instruments enables the minimum level of flotation control and is recommended before upgrading to advanced control methods:

Once the basic set of automation controls are in place, we can provide advanced control solutions that focus on process optimization and stabilization, such as:

We offer two solutions for basic reagent control: gravity controlled dosing and pressure-controlled dosing. Once the basic instrumentation is in place, additional methods such as ratio control and pH control can be implemented.

For plants with regulatory control in place, we offer the Outotec Chena® system, which controls reagent dosing based on electrochemical slurry measurements. Stabilizing and optimizing your process through automation

Manual operation: The point at which the site is operating on the site-specific grade-recovery curve will determine the flotation performance.

Stabilization: With improved flotation controls, the flotation circuit can be operated with tighter safety margins – i.e. the process can be run closer to the minimum grade limit.

Optimization: Improved process conditions (less turbulence, consistent drainage and entrainment, more constant mass pull, and so on) enable higher recovery with the same grade.

Automation systems are tailored to the requirements of each individual plant operation and include installation and start-up support services. The delivery scope can include:

1. Basic process controls:

2. Advanced measurements, controls, and reporting

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice