Fully connected

Smart controls combined with proven equipment

Top size control

Ability to handle and adapt station for maximum production

Multiple steel structure modules

Modular design steel structure components

Capacity

Capacities from 1,000 to 15,000 tons per hour

Foresight™ stations - Optimal production

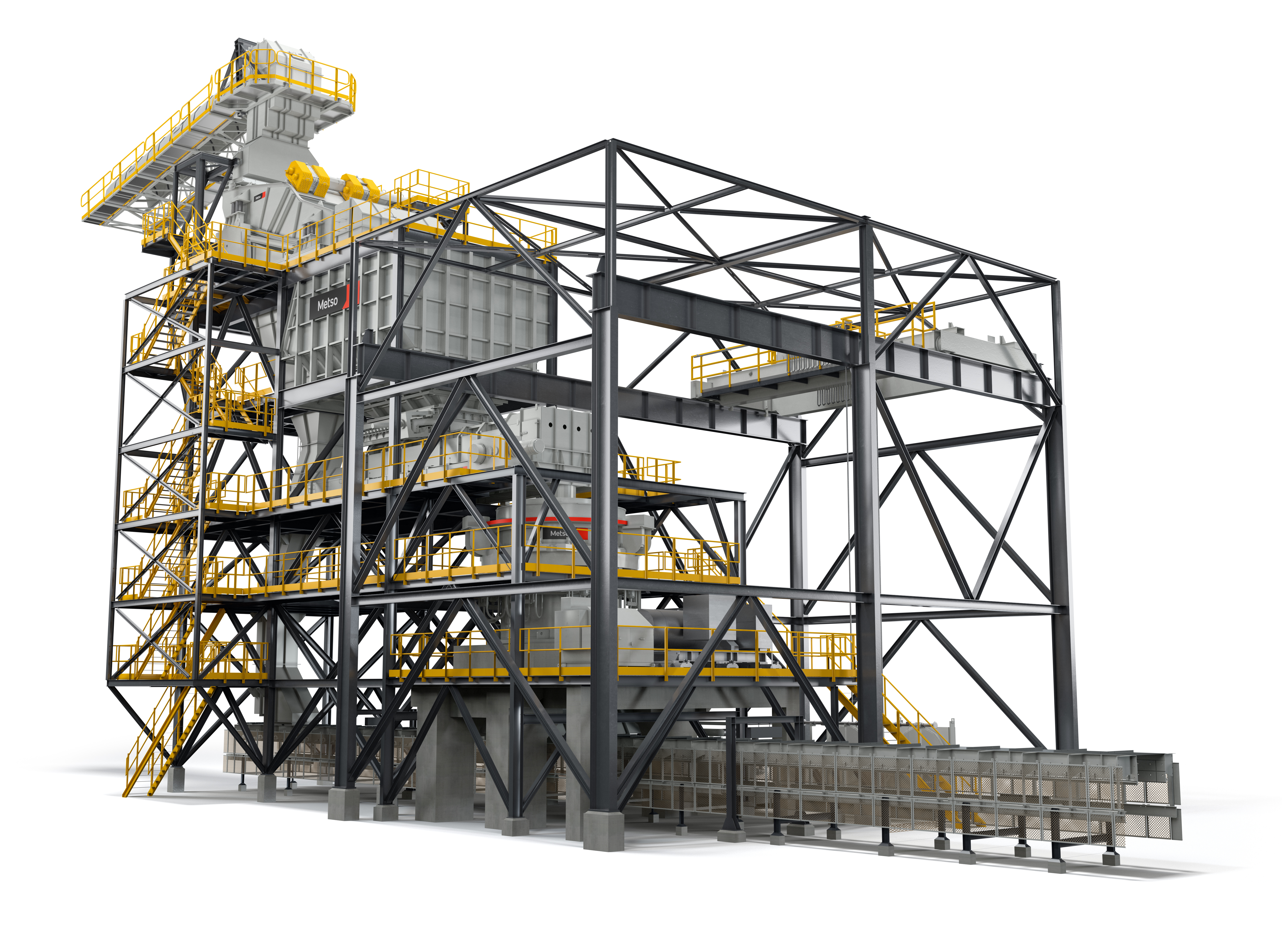

Metso's Foresight™ semi-mobile primary gyratory (SMPG) station is a crushing plant made of steel. The guiding principle is to reduce concrete works to the largest degree and build a modular plant with a focus on ease of installation and associated site-activities, maximizing off-site work, as well as ease of relocation.

The capacity can range up to 15,000 tons per hour and is best used in primary crushing or in pit (In pit crush and convey) applications.

The SMPG station has a modular approach that focuses on a few different pillars to build your optimal station.

Learn more about the SMPG station >

Our featured station for the Foresight™ stations range is the MP cone station. The MP cone station is a fully connected plant for capacities up to 6,000 tons per hour and offers a lead time of 40 weeks (FCA).

This station also will reduce plant footprint due to the use of multiple pieces of equipment in a compact design and eliminates the need for other equipment downstream.

Applications include secondary or tertiary crushing, or can be used for direct feeding to a high pressure grinding roll (HPGR) or a SAG mill.