Improved operational safety and furnace availability

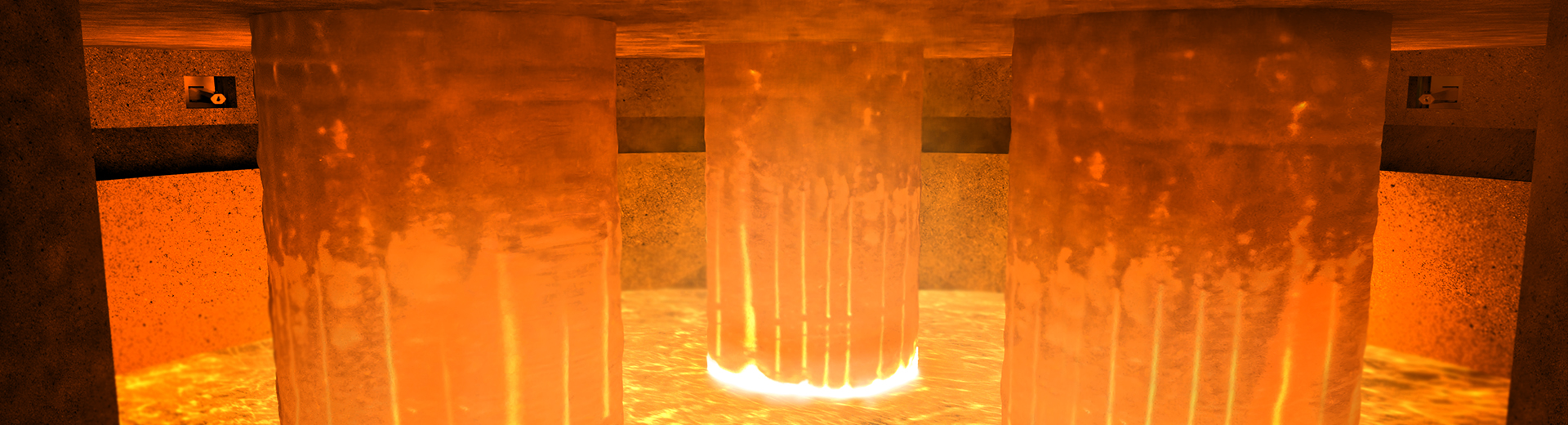

Metso's Outotec Furnace Camera provides a clear picture of furnace conditions regardless of fumes and dust in its field of view. This eliminates the need to manually open hatches or shut down the furnace for visual inspections, improving operational safety and significantly increasing furnace availability.

Improved response time

Operators can identify abnormal situations such as water leaks, electrode breaks, or hot spots early and address them quickly and safely. This mitigates disruptions to production.

Quick and easy installation

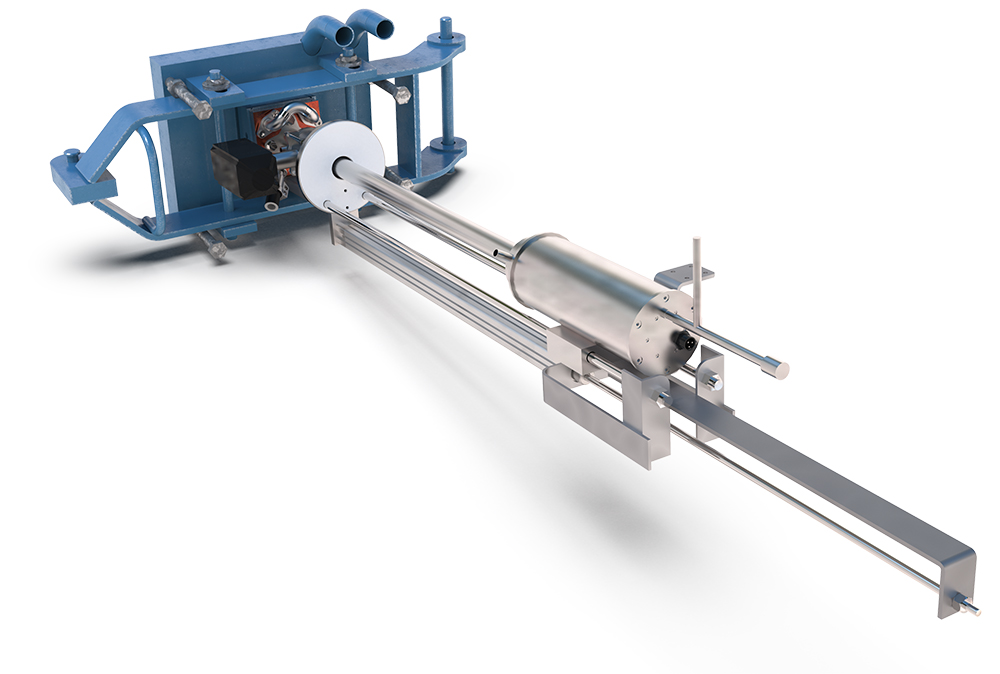

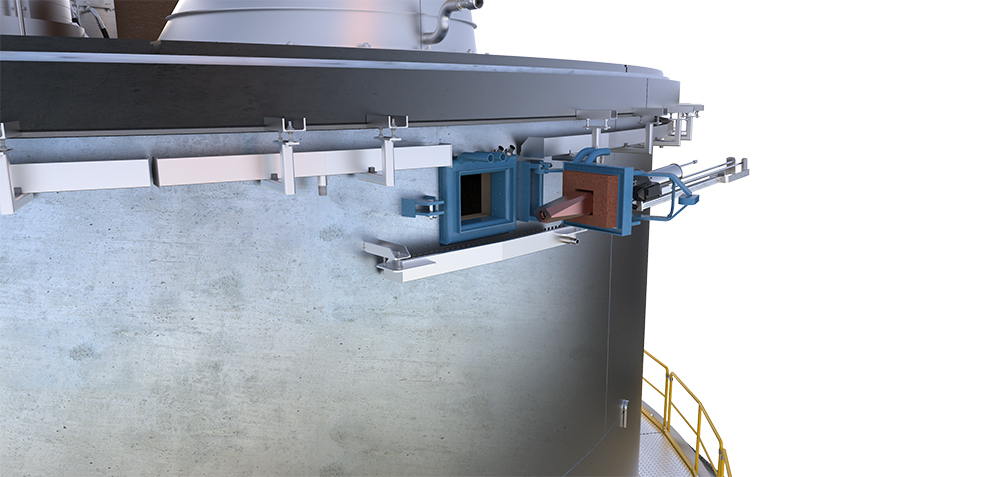

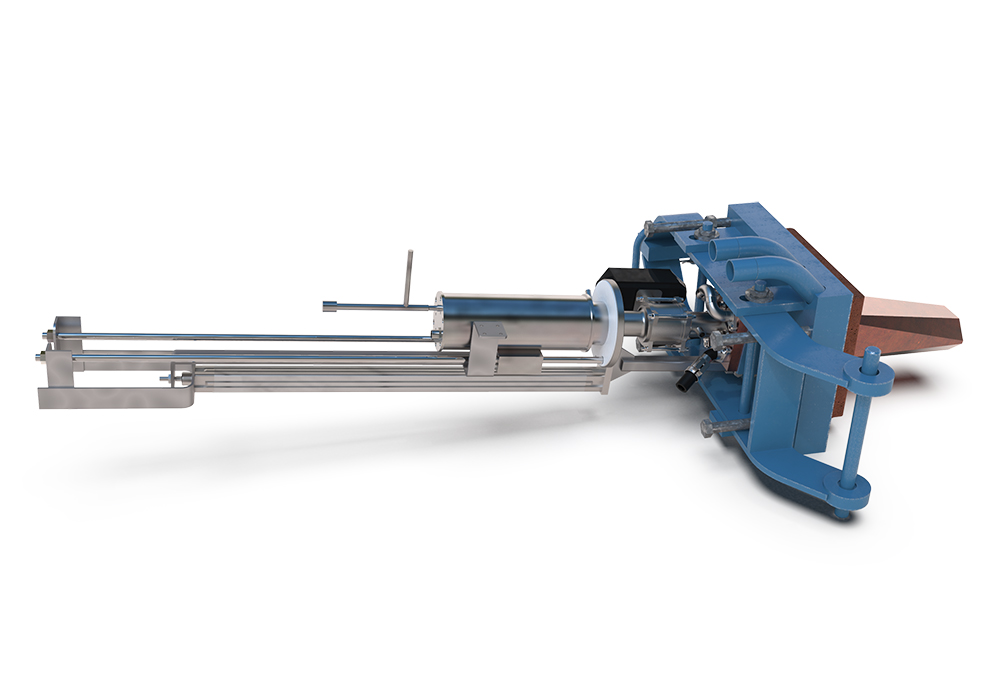

The fully integrated solution is designed and manufactured according to the requirements of each individual customer application. In addition to the camera system, we can deliver high-quality hatches and cooling solutions for modern furnaces. The system is fully tested before delivery and the bolt-on design enables quick installation and commissioning without disrupting production.

Reduced operational costs

Metso's Outotec Furnace Camera includes efficient cooling for the camera optics, which significantly reduces nitrogen consumption, effectively protects the lens, and reduces maintenance needs. This reduces operating costs compared to traditional furnace monitoring solutions.

Intelligent and user-friendly system

The system includes an automatic retraction function to protect the camera in case utilities supply is lost (power, water, instrument air, or nitrogen).

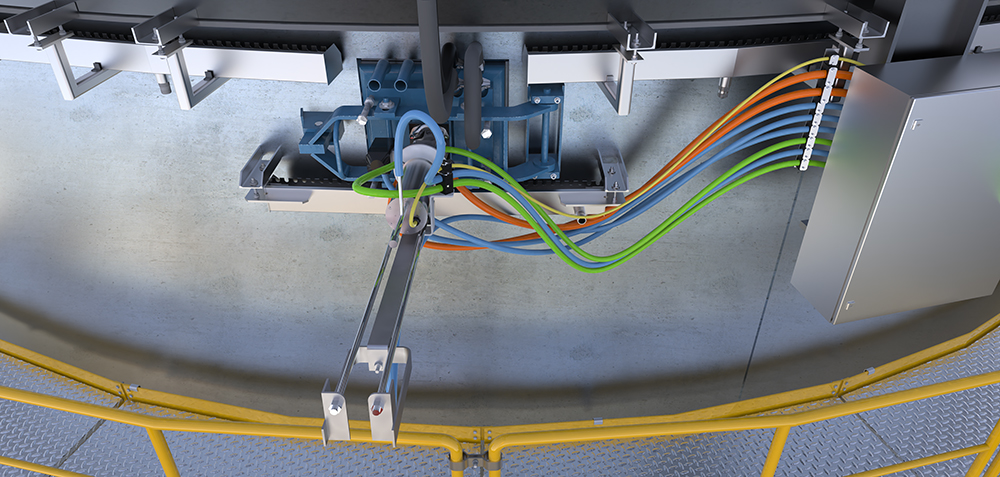

The system can record video, snapshots, and historical trend data for specific areas of the furnace interior for later analysis. The data can be transferred to the plant automation system or viewed from the control-room display.

Full-service support for maximum benefit

Metso experts provide support during commissioning of the system and comprehensive training for operators and management personnel to ensure the maximum benefits of the system are realized.

Metso can also provide technical support for users and system upgrades via an optional remote connection service.