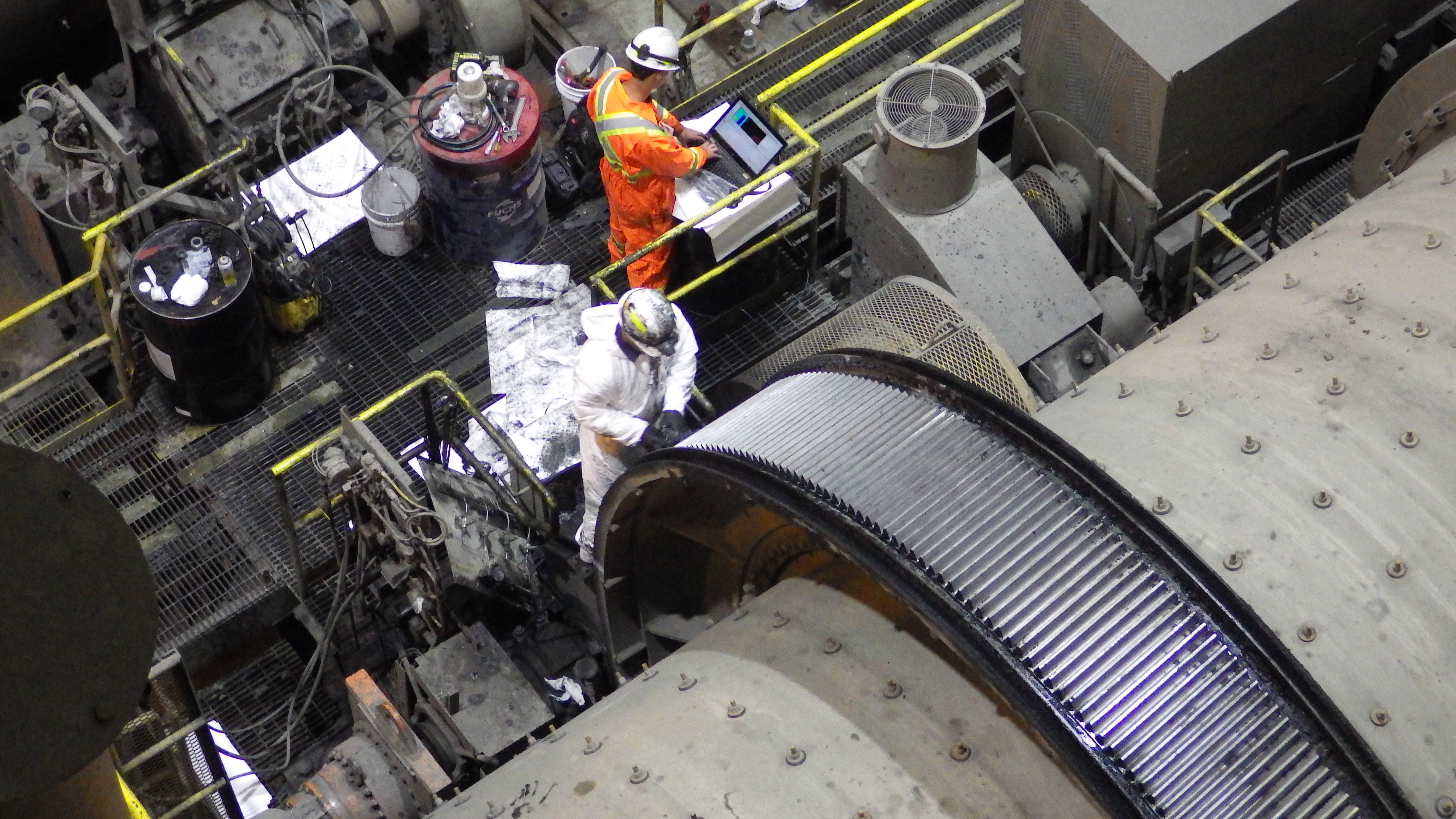

Digital gear inspections

Accurate digital inspections of the entire girth gear are performed quicker than any other inspection method available!

The cleaning formula is non-hazardous and non-corrosive

Flushing is performed during production in under an hour

Cleaning is a fundamental aspect of maintenance to control the risk of contamination, quality and safety

Over 20 years’ experience in providing large girth gear cleaning services

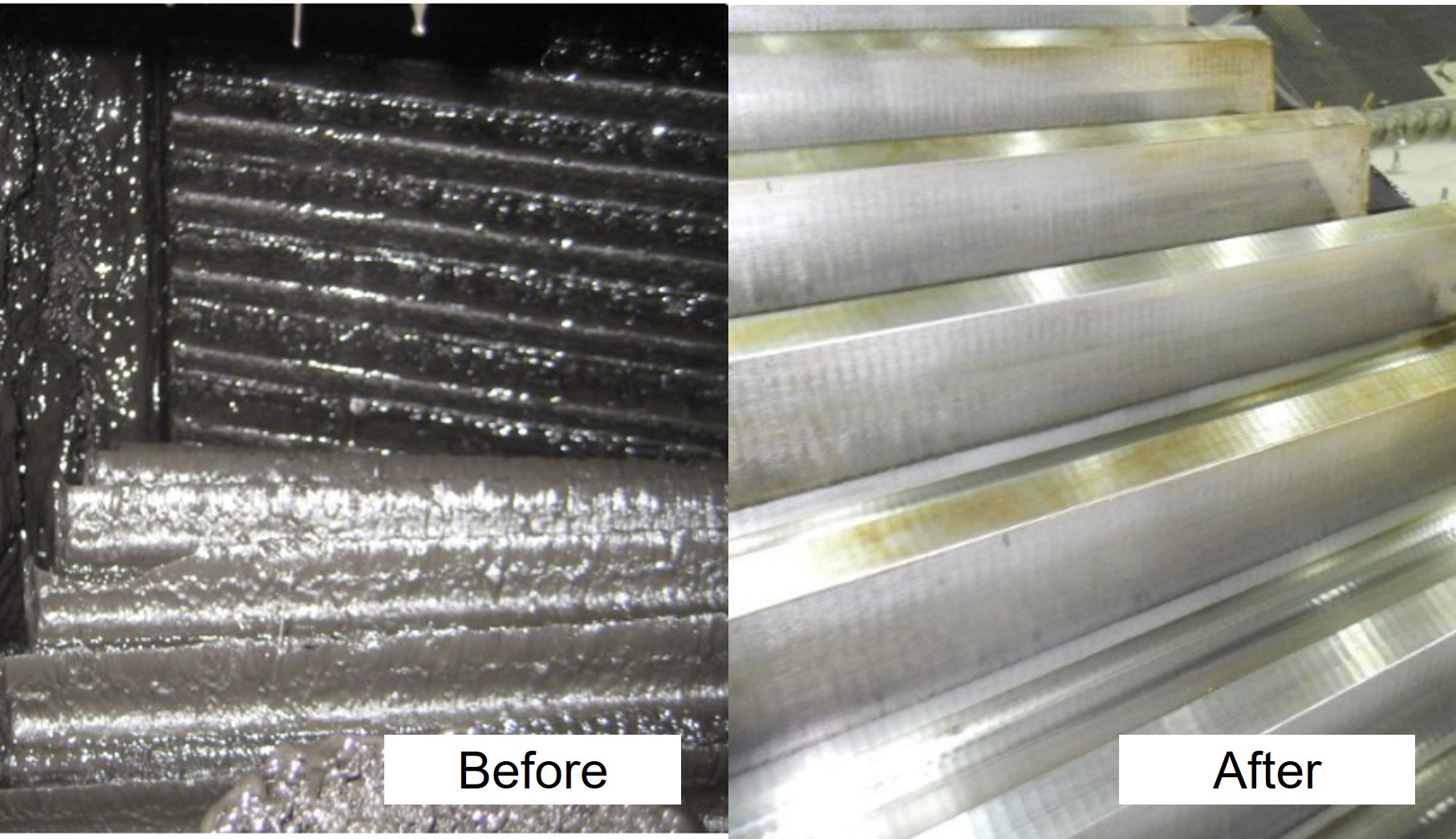

The Cleansolv™ EHF formulation is designed to remove contamination and lubricant buildup on girth gears and pinions prior to inspection. This is accomplished by flushing the girth gear when the mill is about to stop, during grind out minimizing downtime.

The actual time of flushing a gear set is under an hour. There is no need to wipe the gear teeth down or rinse after, to remove residue as in Magnetic Particle or Dye penetrative inspections; if using ASTM E2905 inspection method.

Application is done during operation, minimizing the need for shutdowns and allowing for consistent cleaning without costly downtime. Cleansolv™ EHF’s design also eliminates the need for bulky sprayers or valuable crane time, freeing up resources for other essential tasks.

Gear engineer gear teeth analysis

Gear Engineers worldwide use visual interpretation (AGMA 1010-F14) as the standard used to analyze gear tooth condition, such as contact patterns, alignment and wear patterns.

Routine use of Cleansolv™ EHF not only prolongs asset life but also enhances inspection accuracy, allowing teams to pinpoint and resolve gear issues early. Cleansolv™ EHF’s cleaning efficiency can achieve in one drum what other products often require three to accomplish, delivering better value and performance with less product.

The product’s high levels of Extreme Pressure (EP) and Anti-Wear (AW) additives protect gear teeth during cleaning, minimizing wear and preventing damage often seen with products lacking these agents.

Unlike other solutions, Cleansolv™ EHF doesn’t require complex setup or heating, allowing users to apply it directly without the need to heat drums or protect them from freezing. This streamlined process minimizes carbon emissions, lowering the solution's environmental impact and is part of the Metso Plus offering.

Each drum is suitable for transport with minimal special requirements, further reducing logistics costs and carbon footprint.