Horizontal mill plant units

Horizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service and operation.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

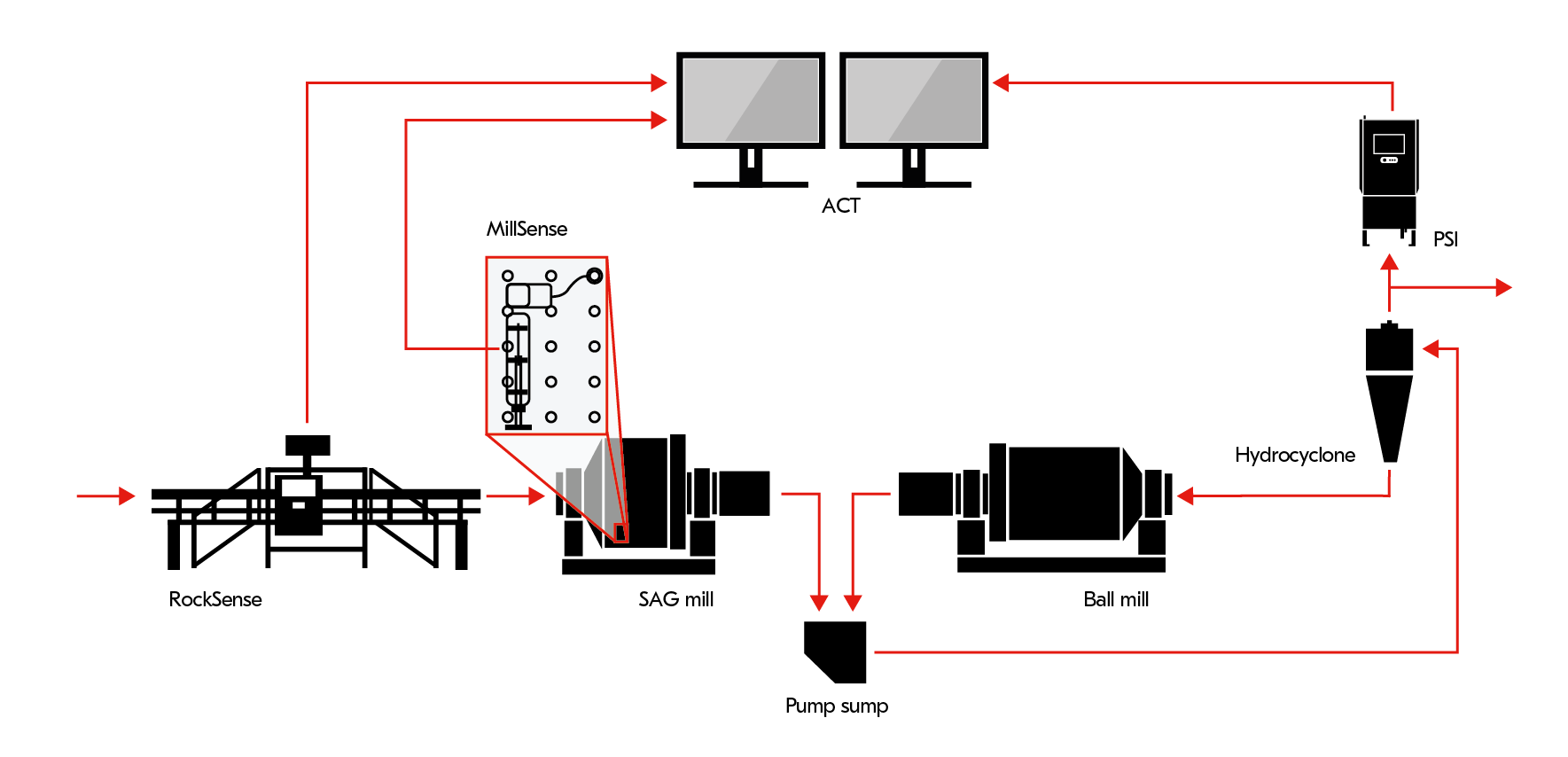

The system stabilizes the process, maximizes throughput, improves control of particle size, and provides accurate on-line analyses of the most critical variables.

The grinding process is very energy-intensive and often a bottleneck for concentrator plant capacity. Grinding is therefore considered a very beneficial target for optimization. It is critical in achieving a suitable ore feed size distribution in order to reach high grinding efficiency and throughput, especially in grinding circuits involving autogenous (AG) or semi-autogenous (SAG) mills. The investment in grinding optimization pays for itself through reduced energy costs and improved productivity.

The RockSense system is an on-line particle size analyzer system for ores moving on a conveyor belt. The system uses high-performance 3D laser imaging technology that is resistant to changes in external lighting conditions. RockSense analyzes the rock particles during normal belt movement without affecting the capacity of the conveyor belt. The excellent resolution and realistic scale of the images is achieved by combining a high resolution 3D laser scanner with a rotary encoder. RockSense provides the following analyses:

• Particle size distribution with user-definable statistical measures

• Cumulative volume flow estimation

The MillSense system provides on-line analysis of the mill charge position and volume by directly measuring the charge’s toe and shoulder angles. The volumetric charge measurement has proven to be an invaluable input for mill optimization and for decreasing disturbances caused by ore changes. The MillSense sensor is directly attached to a liner bolt and uses wireless technology for both power and data transfer.

The benefits of MillSense include:

The PSI particle size analyzer is a market-leading on-line sizing system for mineral slurries. Particle size monitoring and control improve throughput and help to maintain the target grind in the grinding circuit. Additionally, it improves the downstream process by minimizing reagent consumption, increasing recoveries, and making thickening and filtration more effective. Metso offers two particle size analyzers. PSI 300i is the preferred instrument for most grinding control applications to measure P40 to P90 particle sizes ranging from 25 to 1,000 μm. PSI 500i is recommended for applications with particle sizes ranging from 0.5 to 1,000 μm.

Unique in the industry, Metso MillMapper™ allows your maintenance and operational personnel to extend liner life cycles, optimize liner design, prevent liner failures, optimize throughput, and improve the performance of your mill. The MillMapper captures wear data on the entire mill offering reliable reline forecasting. Being able to identify liner abnormalities significantly reduces unforeseen liner failures.

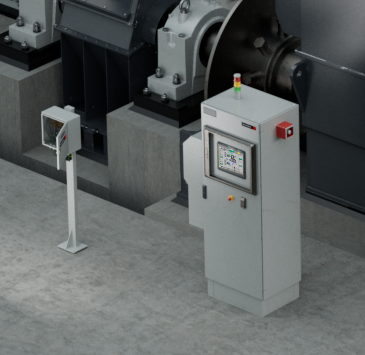

The Standard Control System provides all control functions required for the safe operation of grinding mills and their associated lubrication systems, as well as continuously monitoring the equipment’s condition. The system is a modular solution comprising a local control panel with a fail-safe PLC and a large full-color touchscreen interface, as well as a robust distributed I/O network and smart mill instruments and includes remote expert support.

Learn more about the Standard Control System >

Our pinion temperature monitoring system (PTMS) provides precise information about the operating condition of the pinion and ring gear system by means of temperature measurements of the profile. The pinion temperature monitoring system is available for any installed mill equipped with a pinion and ring gear. Metso offers a complete package that includes a new hatch to accommodate sensor mounting tubes, an air purge pneumatic system complete with a junction box, and thermographic camera and infrared sensors complete with a separate transmitter junction box.