Looking to upgrade your Nordberg® cone crusher?

One size doesn't fit all, and it doesn't have to. Mix and match gyratory crusher upgrades to suit your unique goals and desired investment levels. Maximizing and extending the life of your crusher components allows for a more sustainable operation.

Why upgrade your primary gyratory?

More sustainable operations

Reduced power consumption and less waste from maximized component lifetime

Increased uptime

Shorter and fewer maintenance stops

Optimized capacity

Adding extra production capacity

Lower maintenance costs

Simpler maintenance

Increased Production

Primary gyratory crushers are the first stage in the comminution process. Adding extra production capacity can have significant effects downstream. Metso has introduced advancements that bring increased speeds, higher installed power and mechanical improvements – all designed to bring your production to the next level.

The features are available in the Superior® MKIII, but you can also achieve those same benefits with your previous generation crusher through integrating one or all of our three production upgrade options.

Production upgrades mean:

- optimizing haulage plans

- providing the most efficient energy consumption

- reducing down/idle time

- a more sustainable operation

View the production upgrades below.

Production upgrades

Mainshaft positioning sensor

The mainshaft positioning sensor (MPS) probe enables operators to monitor and adjust mainshaft position, helping determine wear rates.

Better Reliability

If your first stage of crushing is not performing, it will have effects throughout all mineral processing stages. This makes reliability a key concern. Metso has developed five upgrade options that not only minimize wear but also help to ensure a long and productive life for your crusher and its key components while reducing the volume of parts and minimizing waste. Less waste and parts needed mean a more holistic and sustainable operation.

View the reliability upgrade options below.

Reliability upgrades

Offset eccentric gear

The offset eccentric gear allows for better gear to pinion contact, which in turn distributes the load across the complete tooth.

Pinion bearings

The re-designed pinion bearings are capable of higher load handling as well as increased operating speed.

Improved Maintenance

As equipment ages, production efficiency and reliability can decline. Proper maintenance is key to reduce the signs of aging to ensure that your production goals are met. Maintenance can be a costly and labor-intensive job, which is why Metso has engineered six upgrades to simplify and speed up these tasks.

Maintenance upgrades can help lower downtime and require less man-hours needed to perform operations necessary to keep equipment performing at peak level. More uptime means a more efficient and sustainable operation.

View the maintenance upgrades below.

Maintenance upgrades

Pinion bearing & oil level sensors

With sensors built-in, you now have the capability to monitor the pinion shaft assembly, allowing for better maintenance planning.

See it for yourself

1/3

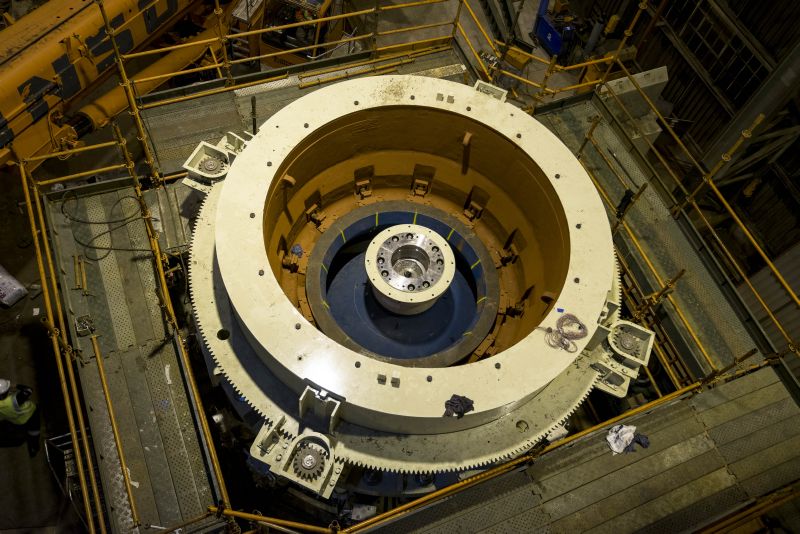

Metso’s rotable shell solution was designed for faster liner changes than a traditional on-site reline, leading to less downtime, higher safely for maintenance teams and improved site Health, Safety and Environment (HSE).

More than an upgrade

Life Cycle Services

Packaged and customizable solutions to help achieve your business goals, from start-up to shutdown to end-of-life.

Contact our experts to learn more!

Your information is safe. Check our privacy notice for more details.

Thank you!

We will shortly contact you. You can send a new inquiry again after 15 minutes.