How it works

The Optimization of the high efficiency scrubber uses plant data in the DCS to understand process variations and adjust the pressure drop set point accordingly.

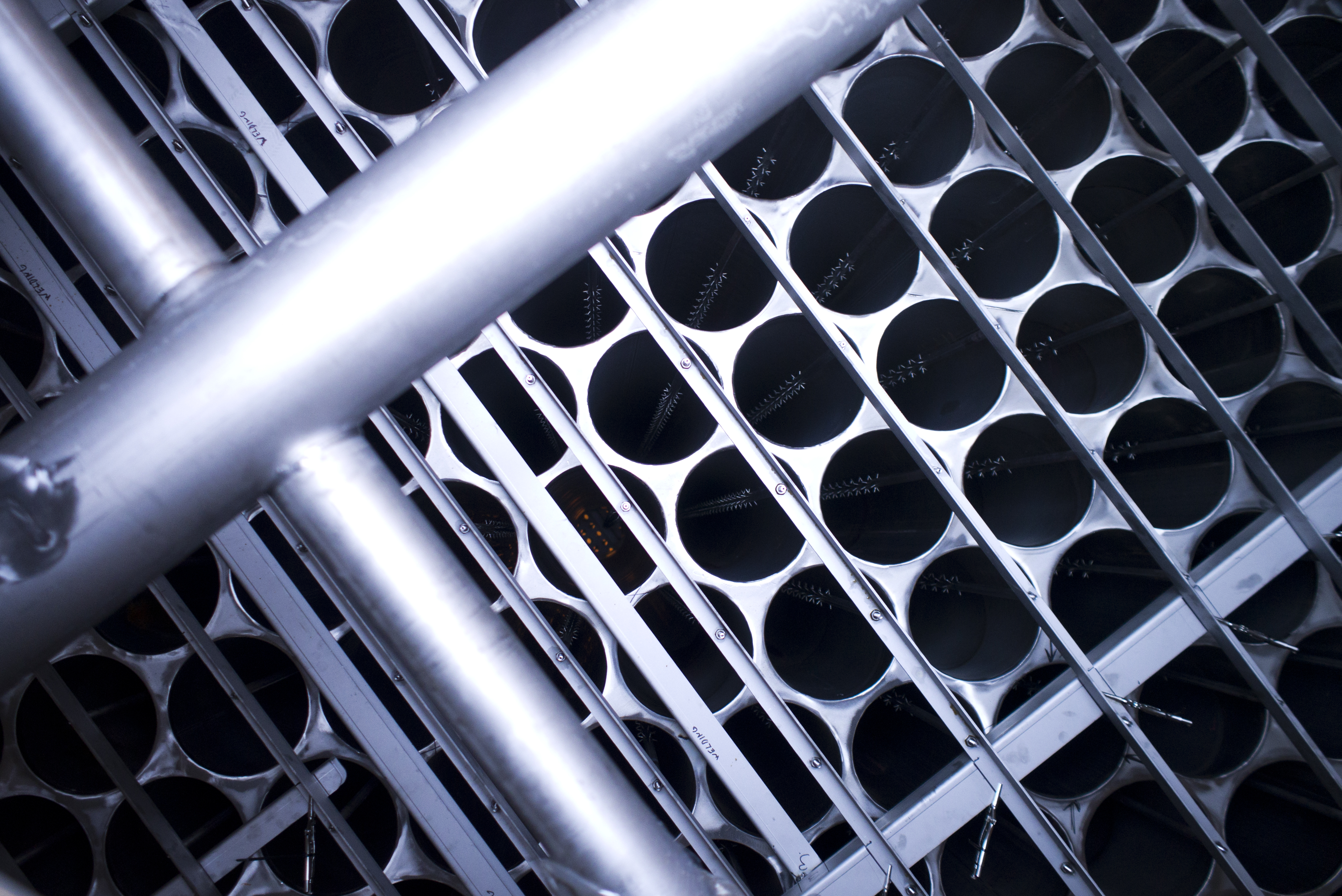

Particles are effectively captured in the HES, but the pressure drop required makes up a big portion of the overall power consumed by the blower of the gas cleaning plant. Adapting the pressure drop to process conditions, and the capacity of the wet gas cleaning in general, can enable substantial energy savings.

Finding the appropriate pressure drop over the HES is dependent on the incoming load as well as the capacity and cleaning requirement of downstream equipment, in particular the WESP section. The Metso WESP Optimizer provides calculations of the spare capacity of the WESP section, which can be used by the HES Optimizer for determining acceptable slip.

As soon as a spare capacity is identified in the wet gas cleaning, a power saving is possible. This power can be saved either in the HES pressure drop or the WESP section power input, or even as a combination of both. Energy saving calculations, sharp boundaries placed on the optimization of each equipment (for example limiting the amount of dust entering a packed tower between the HES and WESP section) as well as removal efficiency calculations, form the basis for deciding where, and to what extent, this spare capacity is best utilized for energy savings.

With spare capacity in design, or at close to nominal conditions, most power is almost always saved in the HES. At lower gas flows, each kPa of pressure drop will require less and less power to compensate, whereas the power consumed in the WESP section wituout limitation is likely to increase. For that reason, at some point it is better to shift the power saving to, or at least include, the WESP section. This is particulary true for plastic WESPs, where the lowered power input will serve the additional purpose of protecting the tubes from damage.

The HES Optimizer can be run independently from the WESP Optimizer, but in doing so it will require more instrumentation and measurement to function accurately. Because of the shared duty for removal of fine particles and acid mist aerosols, the two equipment are excellent candidates for joint optimization, enabled by the comprehensive process know-how of the Metso specialists.