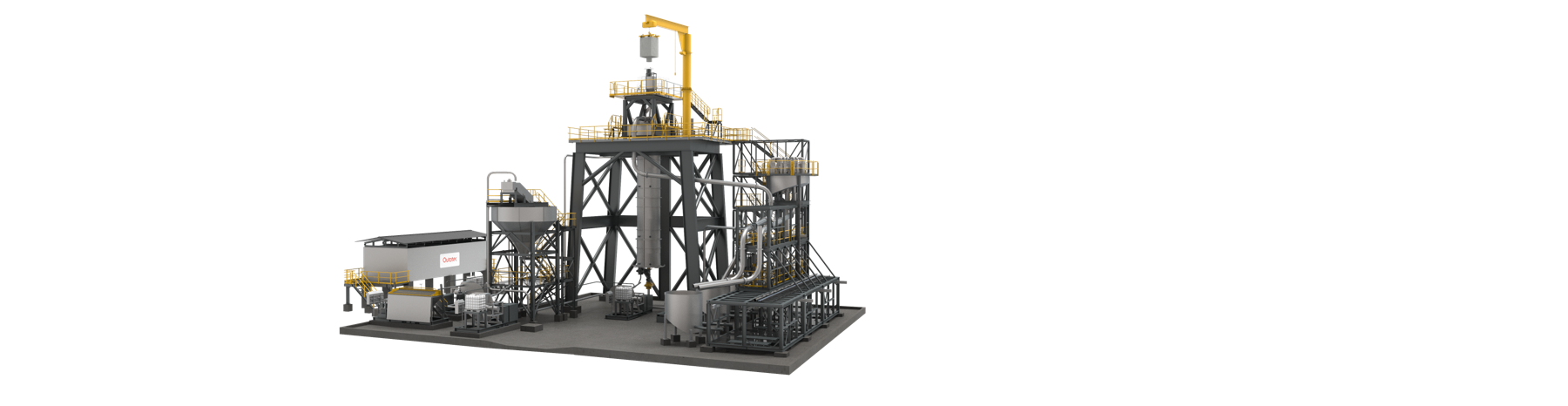

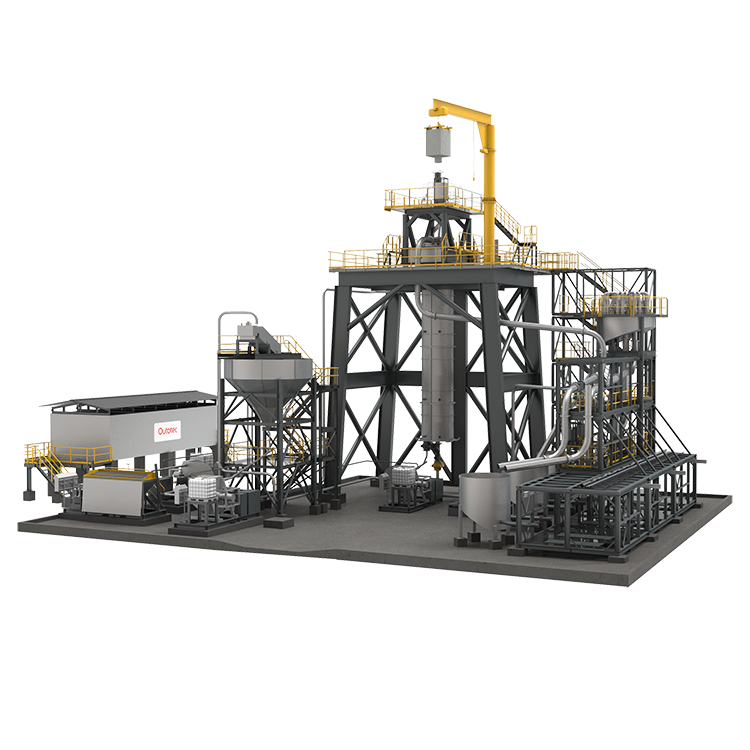

A compact, flexible solution for effective fine grinding

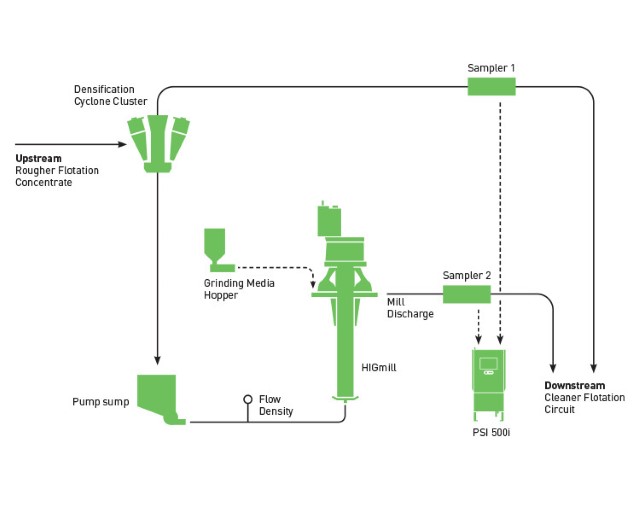

The HMP is a wet open-circuit processing facility for effectively fine grinding slurry to a reduced particle size. Outotec sampling equipment is included in the plant, with accessible sampling points for better process monitoring and risk mitigation.

Modular design for safety and performance

Maintaining safety is one of the biggest challenges in the mining industry, especially during construction and equipment installation. At the same time, to accelerate return on investment and save space, modern plants are built within the minimum possible footprint and time frame. The HMP addresses these conflicting requirements.

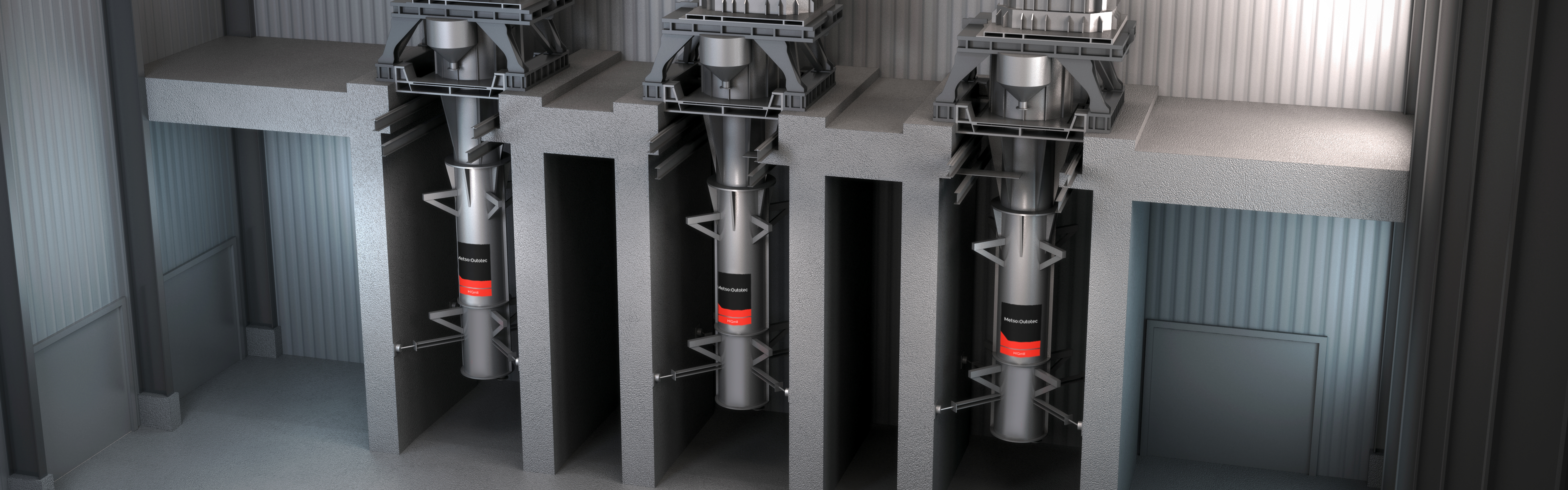

The plant modules are preassembled in the factory and then shipped in sections, which reduces safety risks and maintains the highest possible quality while also reducing on-site construction time and cost. The flexible modules and vertical HIGmill fit in a small footprint and can be arranged to suit the specific site layout, minimizing layout and engineering work. The modular design incorporates industry best practices and can be customized to meet the relevant national standards.

The dedicated switch room allows local control, making the HMP a stand-alone, self-contained plant. The optional media handling system facilitates trouble-free shutdown for inspection and maintenance.

Optimized process

Process conditions in regrind and other fine grinding circuits are often highly variable, and these variations impact flotation and other downstream separation operations, resulting in operational challenges.

Delivery scope

The delivery scope typically consists of a HIGmill, cyclone, hoppers, pumps, media crane, steel modules, switch room, pipes, valves, instruments, and control system. The HMP can be operated and controlled using a dedicated switch room, consisting of variable speed drives, starters, electrical isolation system, and site-compatible control system. An optional media-handling system is available to store media during mill drain and shut down.

Our global team of experts facilitates smooth communication between all parties involved in the project and can provide local support for issues including engineering standards, compliance with local laws and regulations, mining health and safety requirements, and local sourcing.

Services

- Installation and commissioning service packages ranging from basic to EPC

- Performance guarantee testing support and establish the wear pattern of the liner

- OEM spare parts and upgrade recommendations based on process feedback; continuous development of cost-efficient spare parts for longer wear life

- Asset performance services:

- Preventative maintenance, periodic expert assessment and process optimization

- 24/7 remote support

- Training and customer workshops