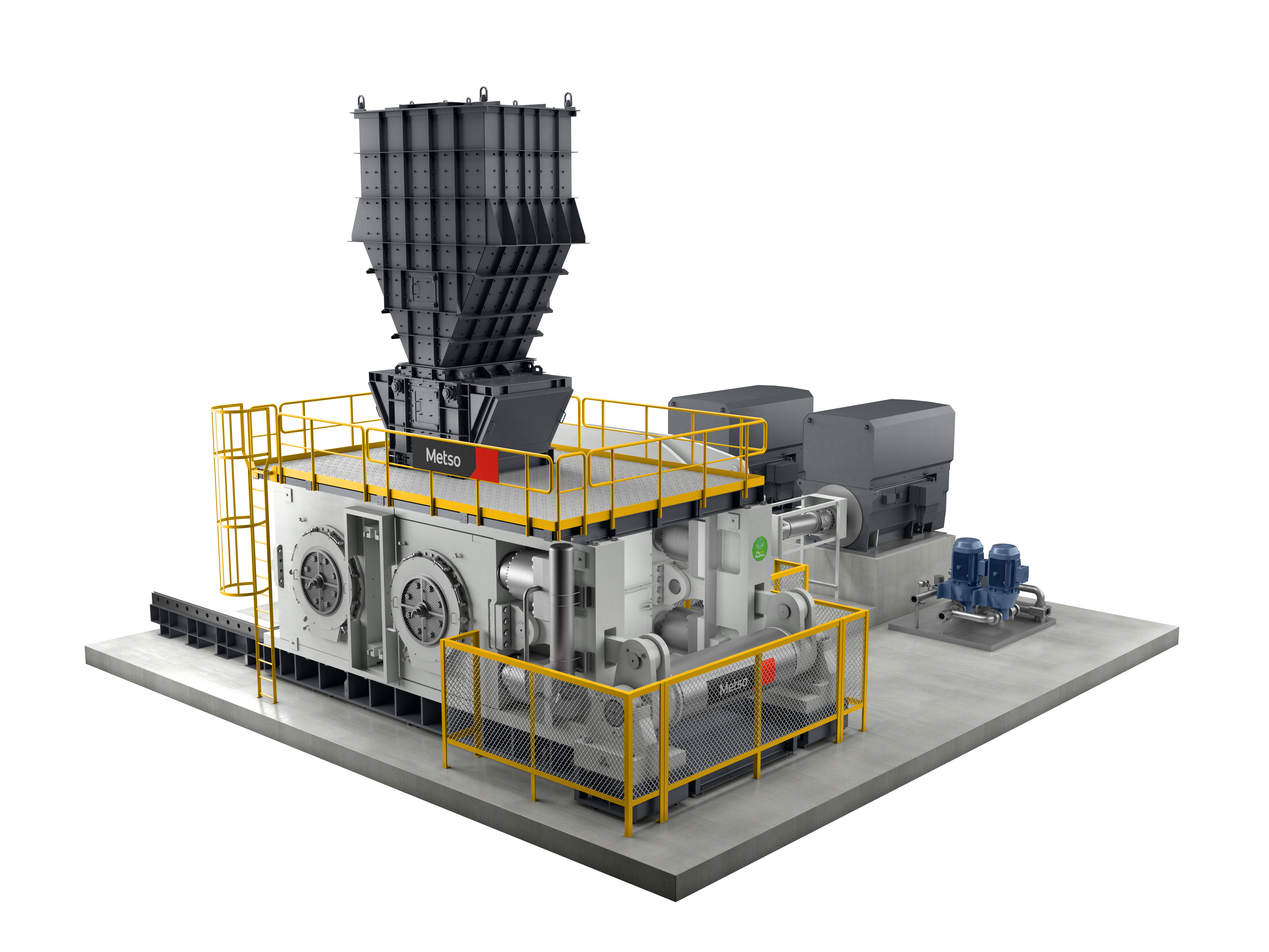

Miss our launch webinar? Watch it on your time!

Our Metso experts presented the HRC™e HPGR, answered audience questions and it can all be found on-demand.

Energy efficiency

Improve energy efficiency by up to 15%

Decreased circulating load

Lower circulating load by up to 24%

High throughput

Increased throughput by up to 19%

Ease of maintenance

Simple edge segment replacement, dust enclosure and unique feed chute design

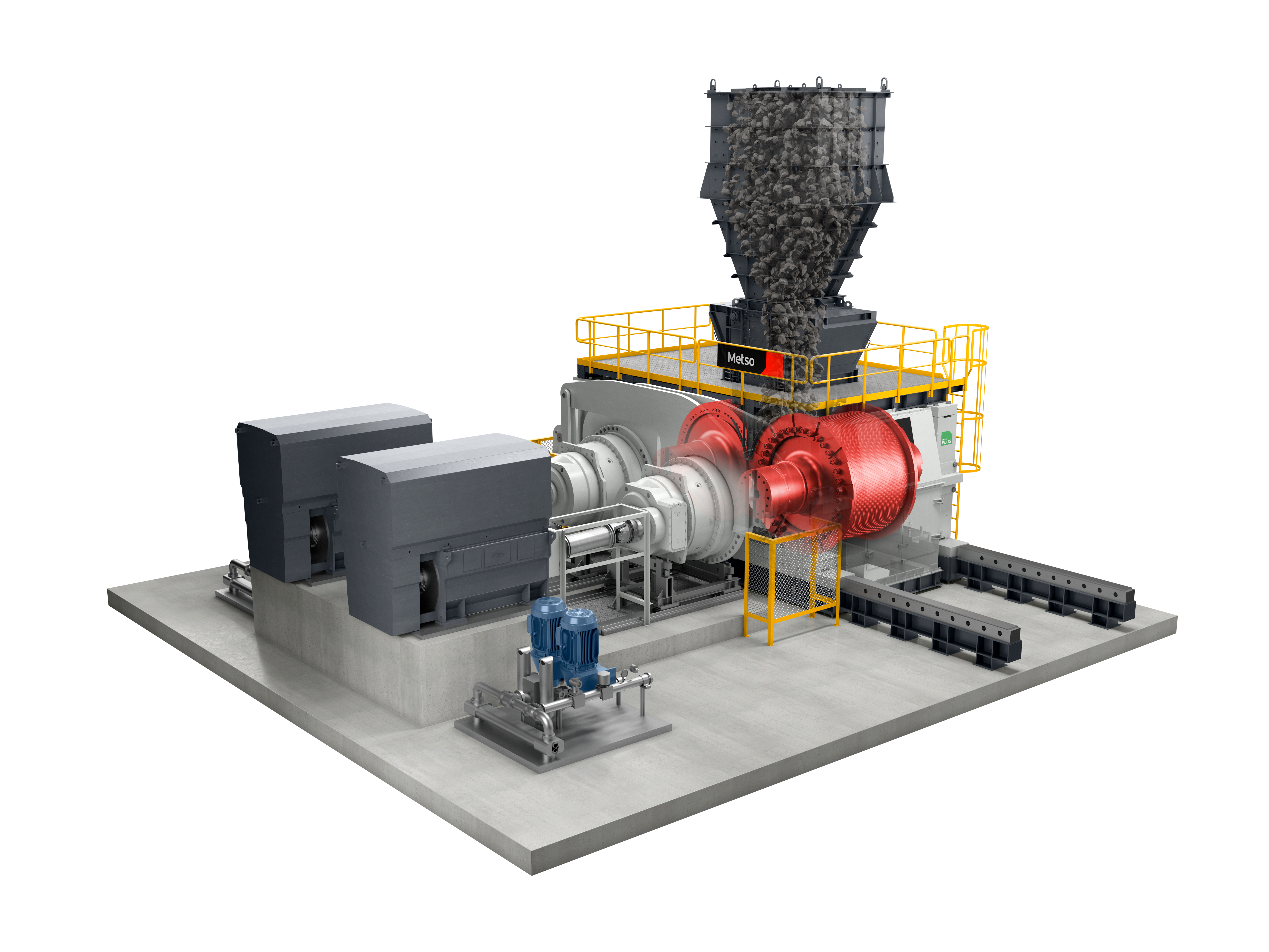

The skew control system is a field-proven mechanical solution that balances the loads by the distributor device ensuring the tires remain parallel for maximum efficiency. The system is also is self monitoring and evaluates skewing, segregation and mechanical condition of the parts.

The skew control system increases availability and reliability of the machine by controlling skewing events and allows for flange rolls assembly.

Metso is the only OEM to successfully operate reliable flanges. The flange rolls eliminate the edge effect by evenly distributing the material, which also maximizes the amount of crushed material during the process.

The HRC™e HPGR flange rolls bring improved energy efficiency, reduces the circulating load and increased tire life.

HPGRSense™ is a digital solution for monitoring your HRC™e high pressure grinding rolls. This stand alone system provides continuous simultaneous monitoring of the rolls.

Operators receive frequent reporting on the roll surface condition. The scanning device uses an array of sensors to inspect the roll surface, and detect anomalies and wear. This gives the ability to predict service life and maximize efficiency of spare stock holding. The scan report will not only deliver key metrics, but a 3D representation of the condition of both rolls.

HPGRSense provides maximum visibility of the rolls condition to the operator enabling them to deliver maximum productivity, grind and energy efficiency of their HPGR.

Model | Tire dimension (D mm x W mm) | Max installed power (kW) | Max installed power (HP) | Nominal roll speed (RPM) | Top size (mm) | Typical capacity (tph) |

|---|---|---|---|---|---|---|

|

HRC™1200e |

1200 x 750 |

2 x 370 |

2 x 500 |

23.5 |

42 |

320 - 450 |

|

HRC™1450e |

1450 x 900 |

2 x 600 |

2 x 800 |

21.4 |

51 |

540 – 750 |

|

HRC™1700e |

1700 x 1000 1700 x 800 |

2 x 900 |

2 x 1200 |

21 |

60 |

640 – 1120 |

|

HRC™1850e |

1850 x 1300 1850 x 1050 |

2 x 1400 |

2 x 1880 |

21 |

65 |

990 – 1720 |

| HRC™2000e |

2000 x 1650 2000 x 1350 | 2 x 2300 | 2 x 3050 | 21 | 70 | 1490 - 2540 |

| HRC™2400e |

2400 x 1650 2400 x 1400 | 2 x 3300 | 2 x 4400 | 21 | 84 | 2250 - 3660 |

| HRC™2600e |

2600 x 2000 2600 x 1750 | 2 x 4100 | 2 x 5500 | 21 | 91 | 3300 - 4550 |

|

HRC™2800e |

2800 x 2000 |

2 x 5800 |

2 x 7780 |

21 |

98 |

4320 - 6050 |

| HRC™3000e | 3000 x 2000 | 2 x 6200 | 2 x 8300 | 21 | 120 | 4950 - 6930 |