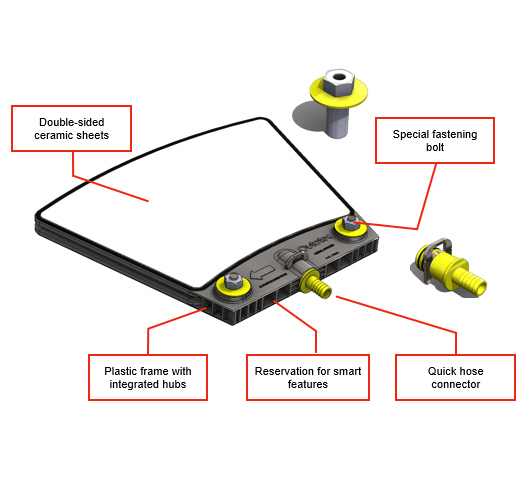

The design incorporates a plastic frame with ceramic sheets and integrated fastening hubs, making the plates 40% lighter. This allows for quicker, safer maintenance of the filter and a decreased likelihood of damaging the plate during installation.

A key driver for the product development was gaining a better understanding of our customer’s needs and challenges and how we could assist in addressing these issues.

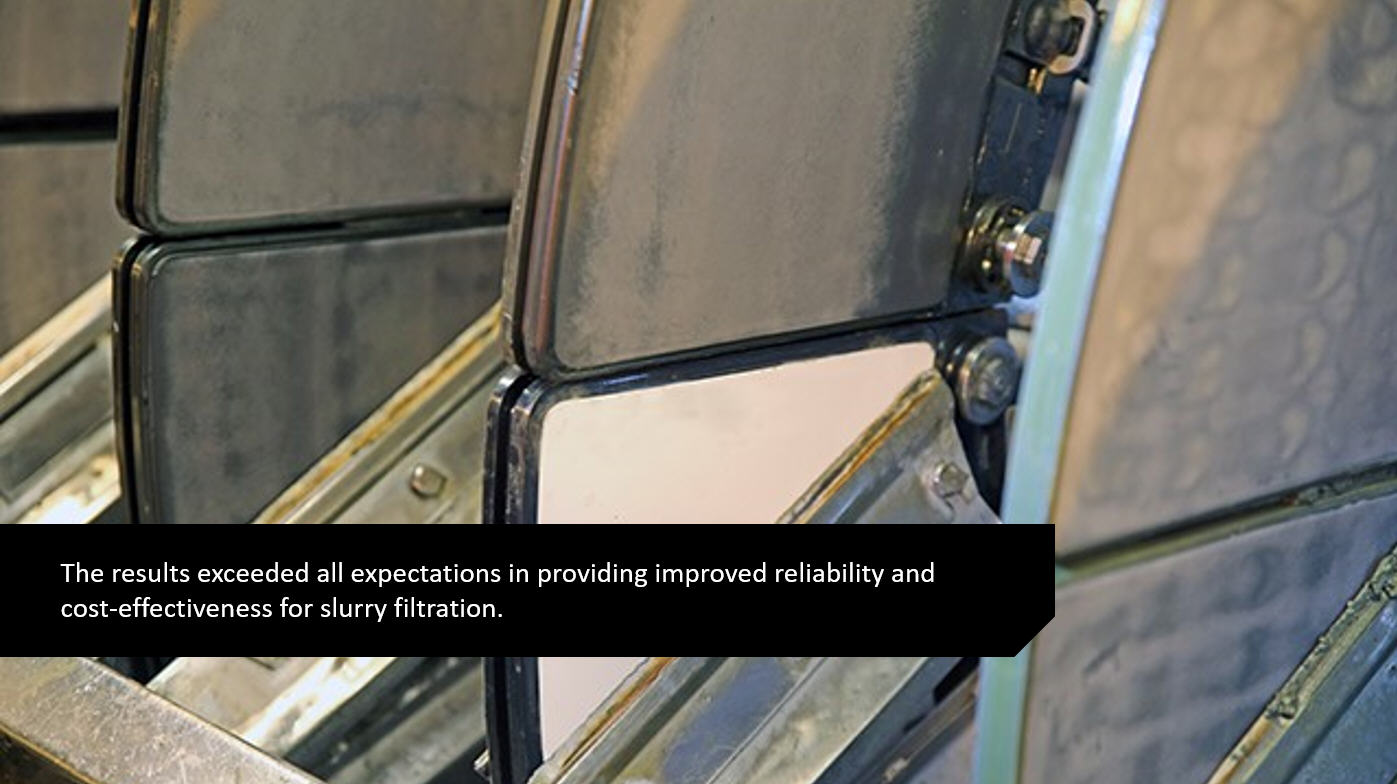

The typical requirements for our customers in the dewatering process are production capacity, residual moisture in the cake, and operational costs. We understand that our customers require a reliable and cost-effective filtration method for dewatering slurries. Reduced residual moisture levels are key to the filtration process, our filter plates have shown a considerable reduction in residual moisture levels with better binding resistance and improved backwash results.

Our Hybrid CC filter plates were therefore designed in close collaboration with our customers as an innovative solution to reduce maintenance costs through improved mechanical life span offering a lower flow resistance inside the plates resulting in higher flow rates boosting the performance of the filter.

The specialized plate fastening bolt automatically ensures the correct torque during installation for optimal tightening resulting in reduced operational costs through shorter shutdown times and improved mechanical life.