Read more about Kaldo L Furnace

Flexible solution for smelting and converting various primary and secondary raw materials

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

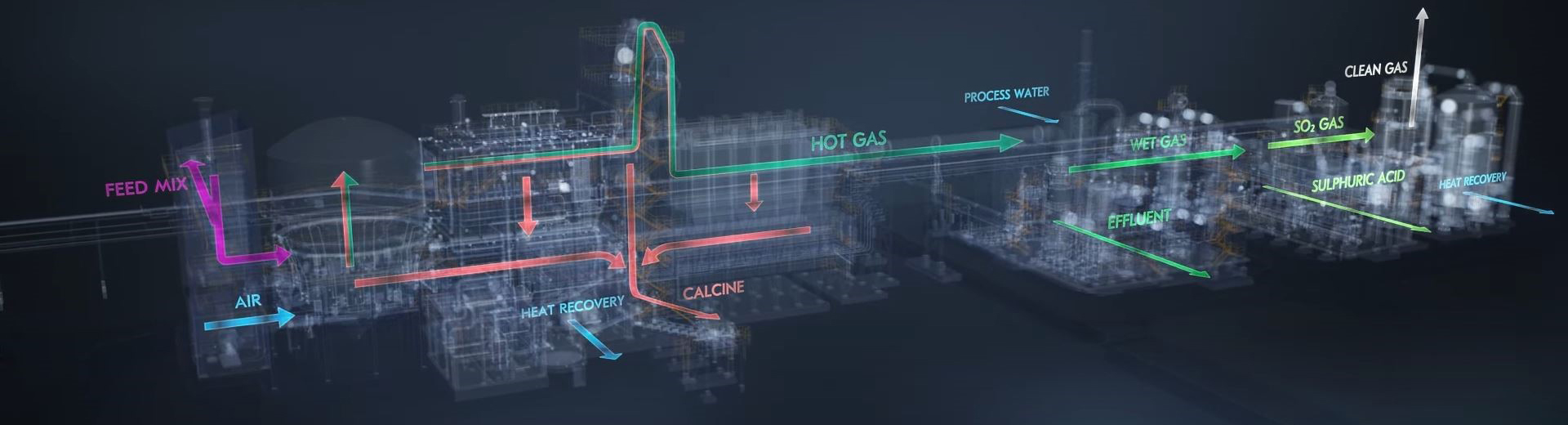

The batch process starts with the charging of material to the furnace. Depending on the process and raw materials to be charged, this is achieved in different ways. Smelting and converting are performed by introducing water-cooled burner and converting lance.

When the processing is finished, the furnace is tilted to pour the slag and alloy to ladles located on a ladle transfer car below the furnace. The process is very compact and fully encapsulated, making it possible to ventilate the whole section to the bag filter and prevent stray emissions. Metso's Outotec process for Kaldo is a well-established solution and has substantial references globally.

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice