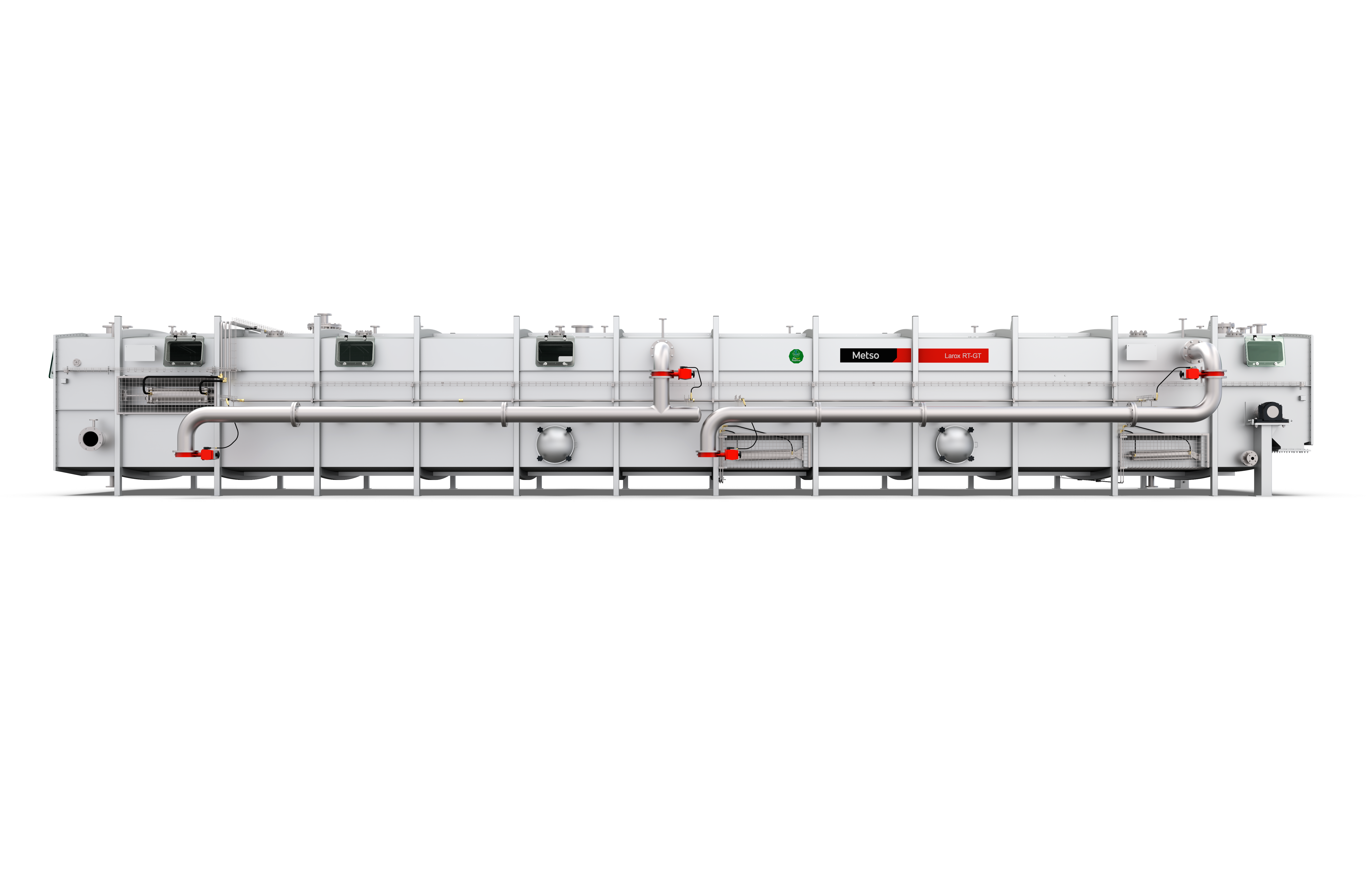

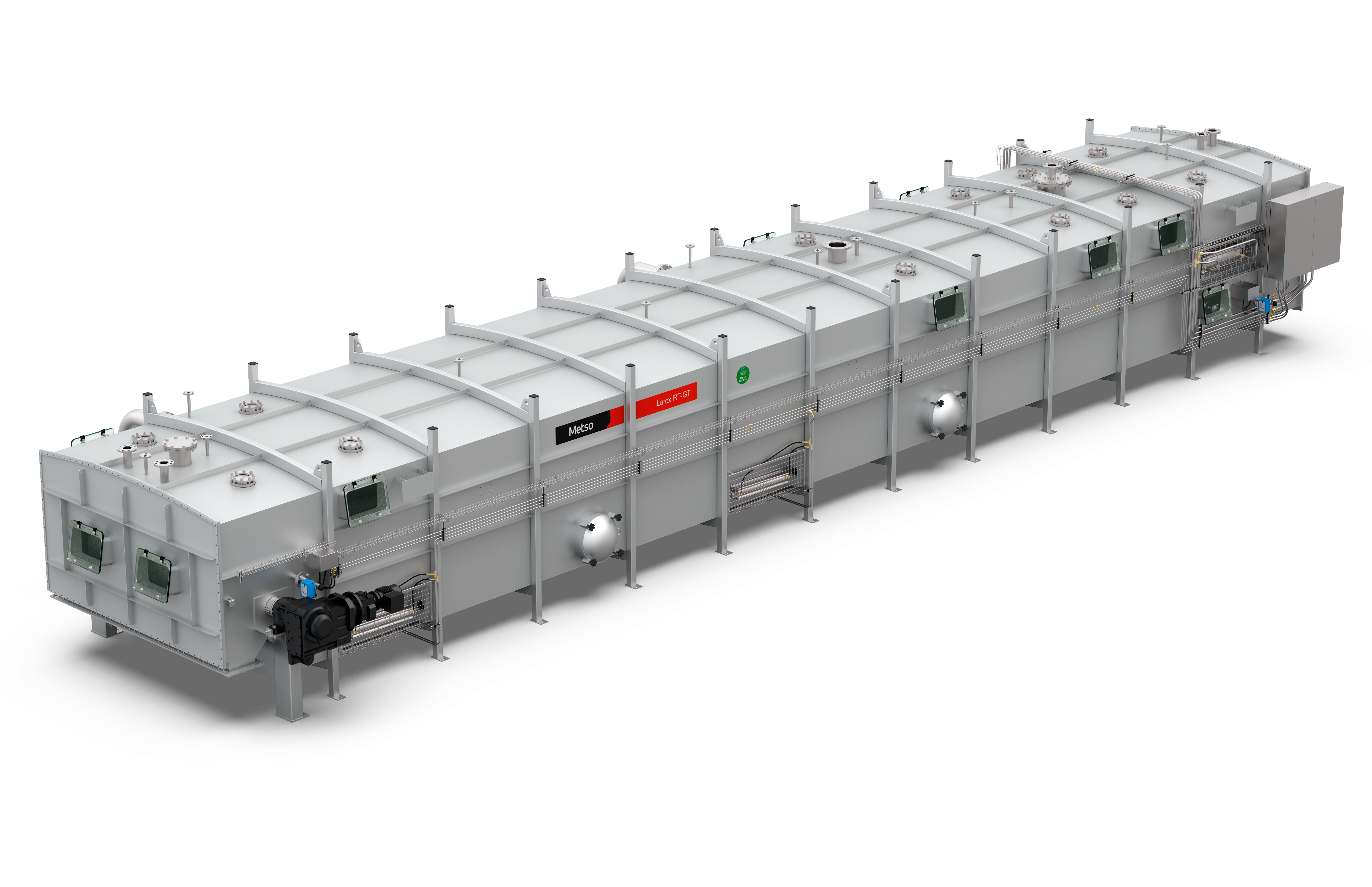

Larox® product family

For more than 45 years, Larox® filters have been appreciated as quality filtration solutions for mining and industrial processes. In 2004, Larox® accquires Pannevis and RT & RT-GT horizontal vacuum filter heritage.