Lokotrack® 40 years

The year 2025 marks a remarkable milestone for Metso as we celebrate the 40th anniversary of the iconic Lokotrack® mobile crushers.

Optimized performance

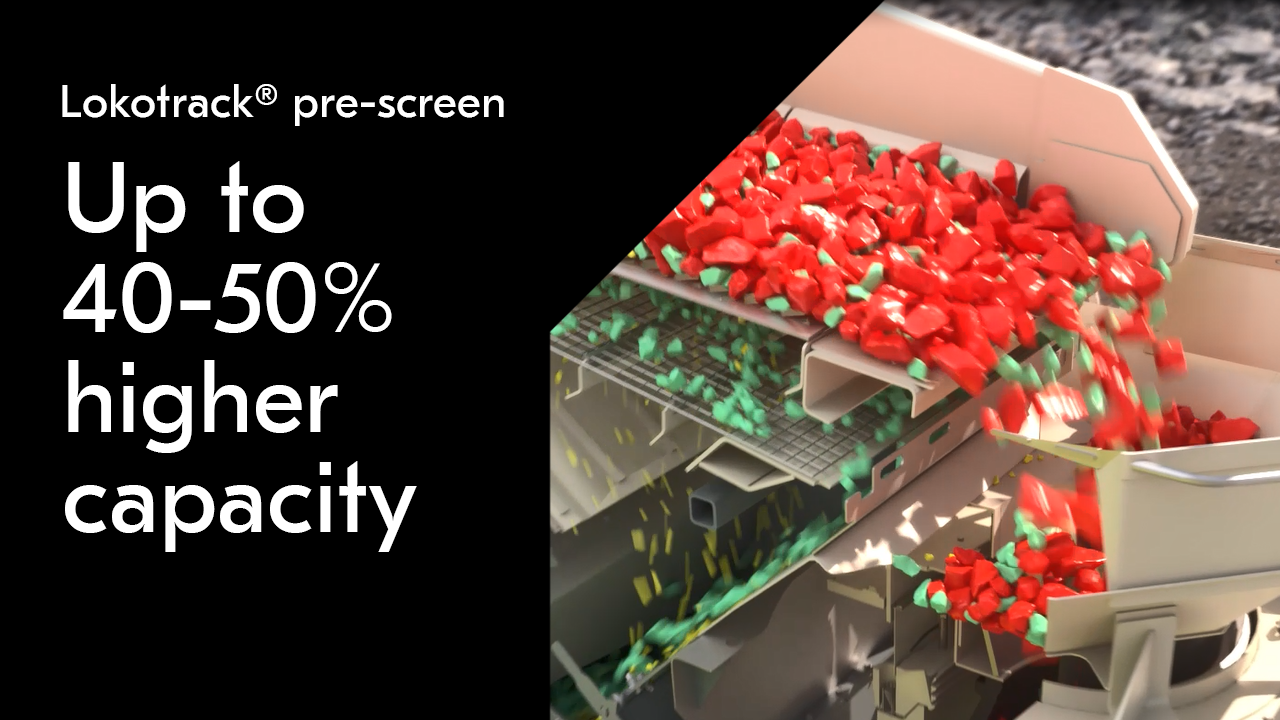

Pre-screen for more capacity

Track-mounted unit

Safe and easy to operate

Lokotrack® LT220GP™ features a robust Nordberg® GP220™ cone crusher unit which provides 220 kW (300 hp) crushing power for high capacity. Nordberg GP220 crusher brings long-term performance, superior reliability and versatility to your operations. It is also one of the smaller models in Nordberg® GP Series™ cone crushers family and fits perfectly to compact mobile crushers designed for road transportation.

Lokotrack® LT220GP™ comes with a CAT® engine and direct v-belt crusher drive ensuring the best fuel efficiency. Direct drive for crusher with purposely designed gearbox and hydraulic clutch makes Lokotrack® LT220GP™ a highly reliable unit.

Lokotrack® LT220GP™ is available with a belt feeder or a 2-deck pre-screen. Together with a powerful crusher a pre-screen offers up to 50% more capacity compared to smaller units in the LT range. Small feed can bypass the crusher and go straight to the product pile or further in the process, increasing overall output, decreasing wearing and enhancing product quality. It also enables to change the process easily from 0/32 mm to 0/16 mm.

The Metso IC™ process control system optimizes crushing results. It allows one-button start and stop, with built-in troubleshooting and a variety of parameter selections. All Lokotrack® mobile crushers in the same crushing process can be connected to the Metso IC™ system. In addition, the entire process can be conveniently monitored and controlled from the excavator's cab using the Metso Remote IC application for remote process control.

Metso is investing heavily in its equipment safety and easy maintenance. In Lokotrack® LT220GP™, safe and easy daily operations are ensured with extensive services platforms as well as safe walkways on both sides of the unit that fold automatically for transporting in one piece.

For safe and easy maintenance, the main conveyor can be lowered down to ground level.

Lokotrack® LT220GP™ is mounted on tracks and can be easily moved inside a quarry and transported between sites on a low bed truck.

The robust main conveyor has a hydraulic height adjustment for combining with other machines. Lokotrack® LT220GP™ is available with an extended main conveyor to allow more feeding height for downstream crushing and screening processes.

Optional side conveyor can be added to transfer fine material to the stockpile beside the machines.

Lokotrack® LT220GP™ can also be delivered with dust encapsulation, high-pressure water spraying system, bypass filters for hydraulic/lubrication oil, fuel pump with truck connection and many other improvements.

Model | Lokotrack® LT220GP™ |

|---|---|

| Crushing unit | Nordberg® GP220™ |

| Feed opening | 210 mm (8,3") |

| Pre-Screen | 2 decks 1,2 x 1,8 m (3' 11" x 5' 11") |

| Engine | CAT® C9.3B 310 kW (416 hp) |

| Transport dimensions | |

| Weight | 38 500 kg (85 000 lbs) |

| Widht | 3000 mm (9' 10") |

| Height | 3500 mm (11' 6") |

| Length | 19 000 mm (62') |

*) The technical details provided are based on the basic configuration and should not be used for obtaining transport permits.