Comprehensive portfolio

Proven technology for magnetic separation circuit with in-house testing for equipment sizing & flowsheet design

Superior metallurgical performance

Separation of fine, weakly magnetic minerals leading to enhanced metallurgical performance

Operational functionality

Complete plant functionality with focus on automation, sampling analysis & low-maintenance

Key challenges in magnetic separation circuits

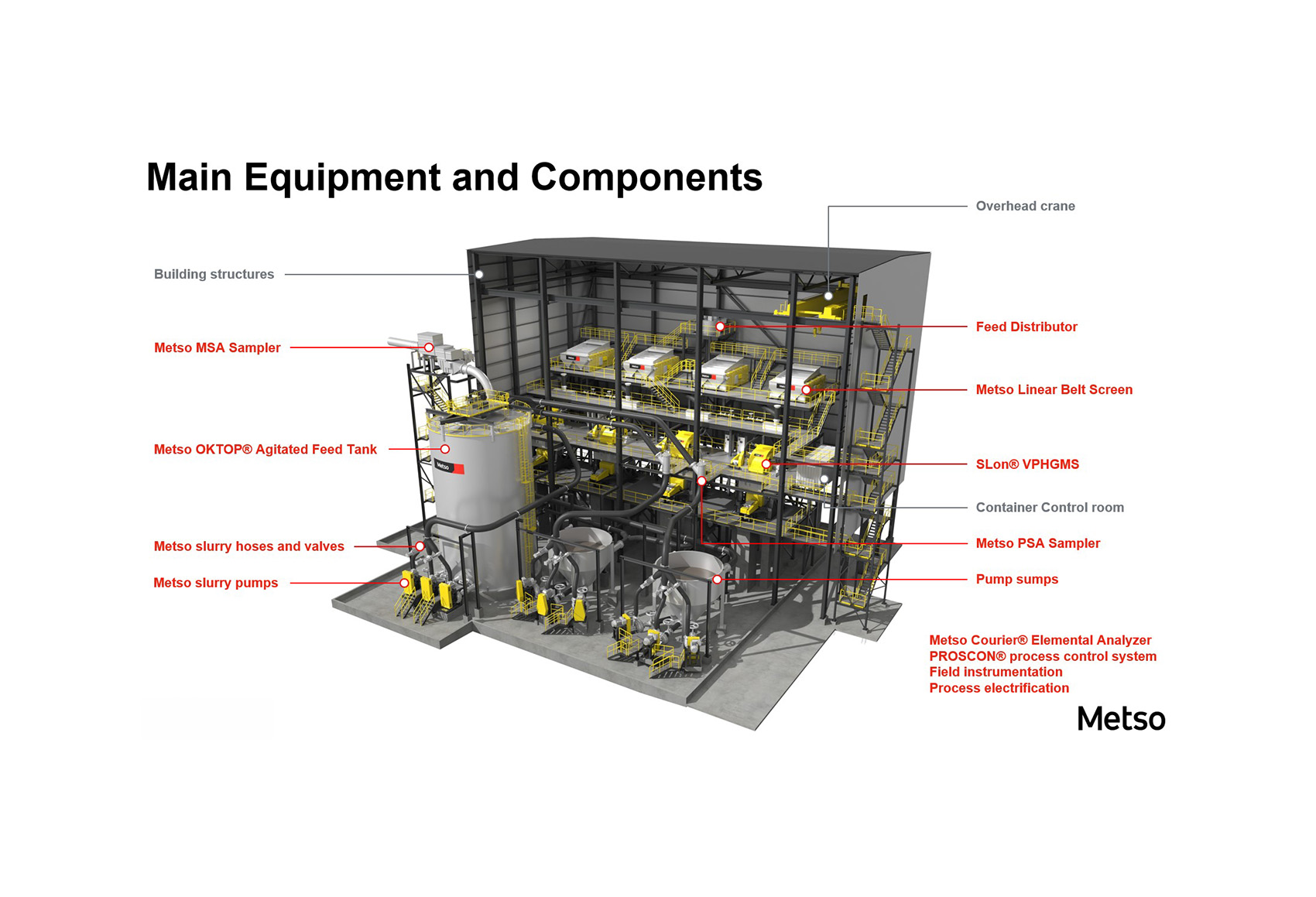

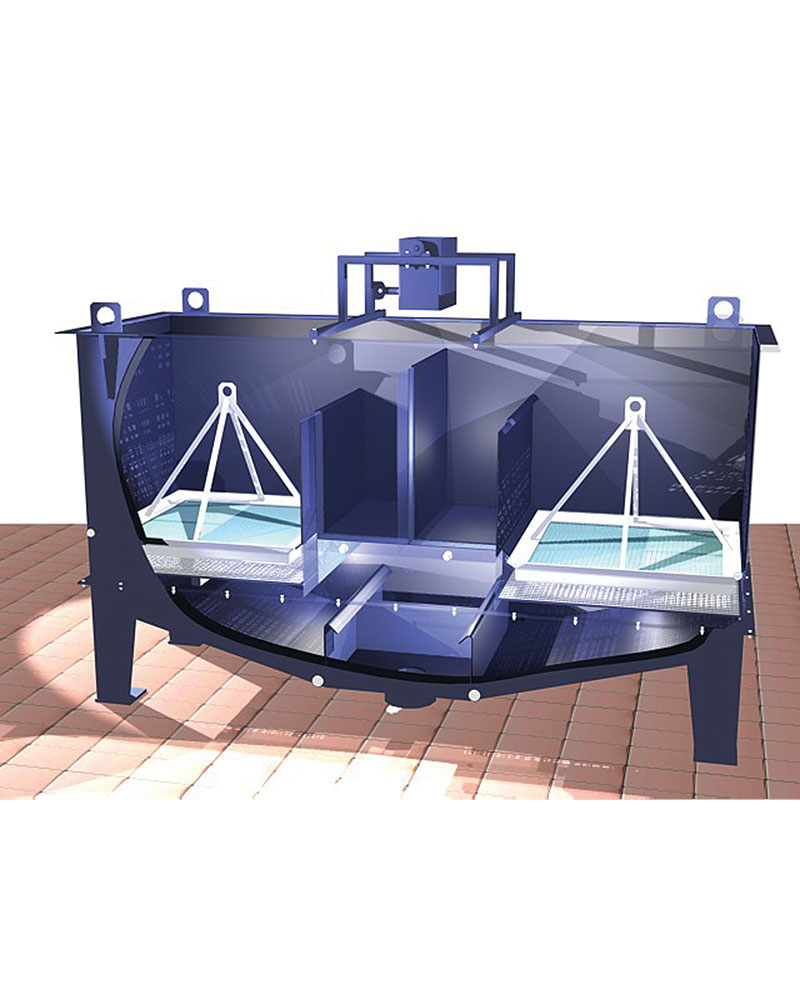

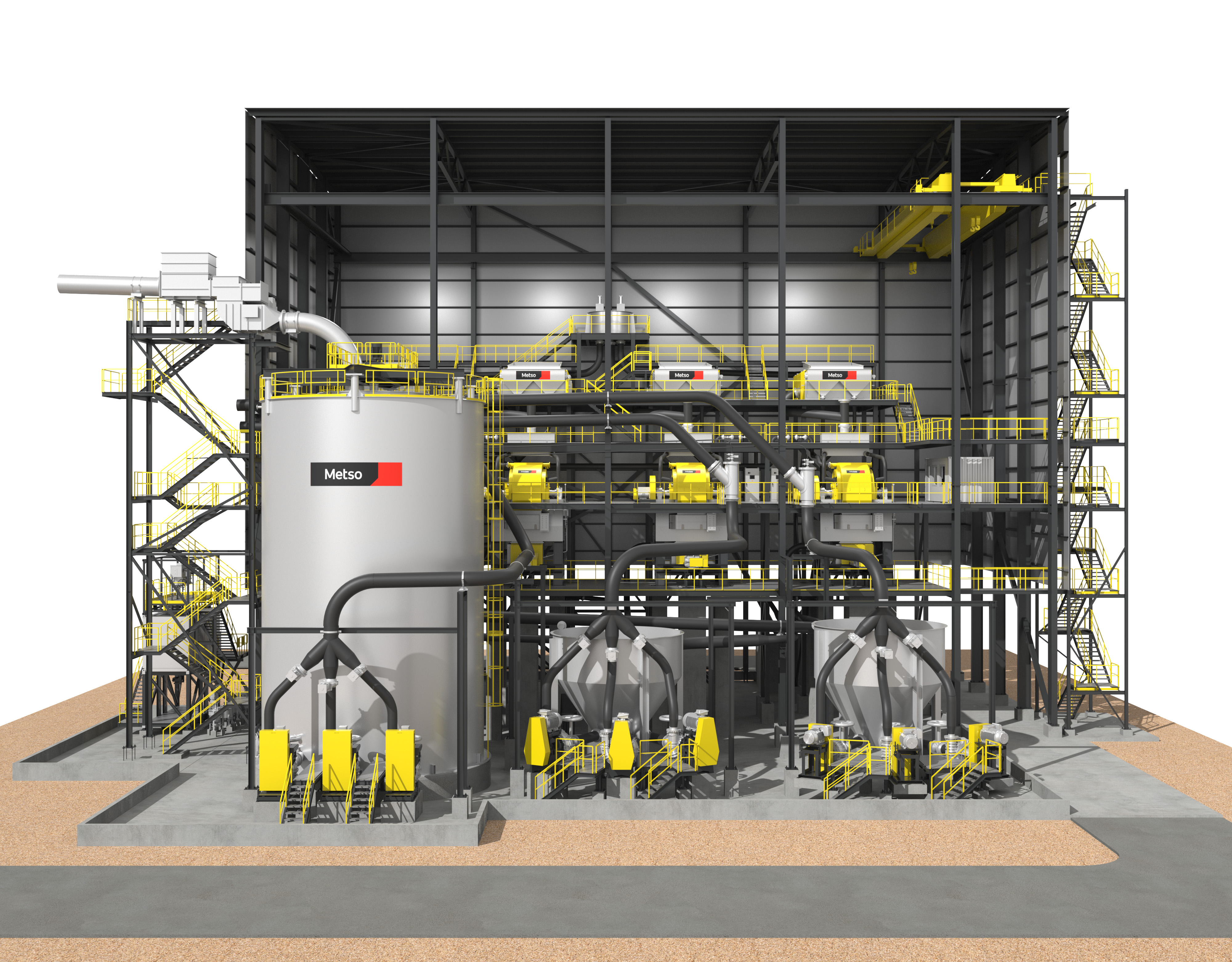

As the industry leader in technology and modularity, Metso Magnetic Separation Plant Units provide unrivaled selectivity, resulting in high recovery of fine and ultrafine particles and ease of execution. Comprising of advanced magnetic separation process know how and sizing, SLon® Vertically Pulsating High Gradient Magnetic Separators (VPHGMS), Metso High Gradient Magnetic Separators (HGMS), and/or dry and wet Low Intensity Magnetic Separators (LIMS), OKTOP® feed tanks, slurry pumps, hoses and valves coupled with process control system and various ancillary products and sampling systems, these Plant Units are your reliable partner to support the entire magnetic separation plant life-cycle

Industry’s most comprehensive scope of supply

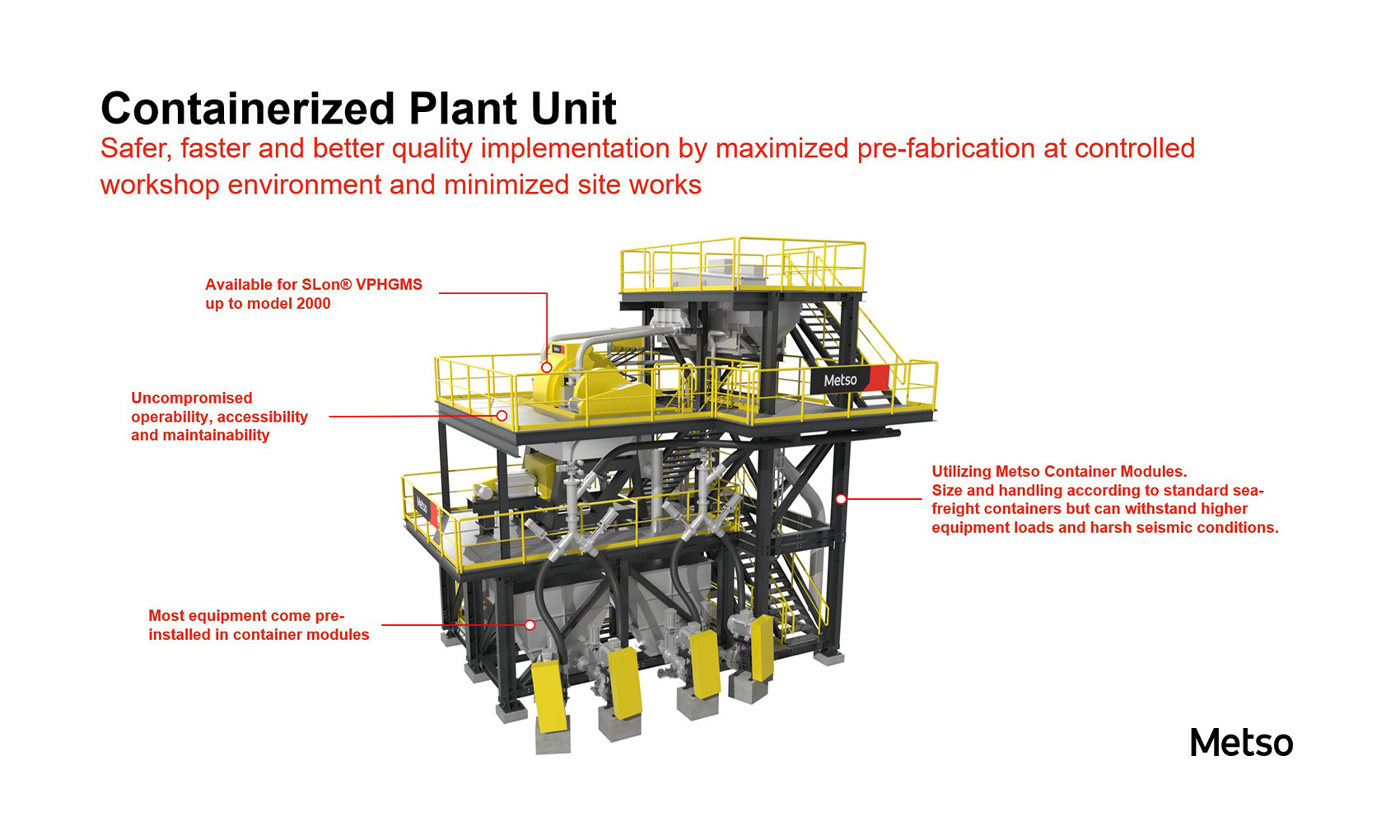

Description: Prefabricated container modules

SLon® sizes: 1250, 1500, 1750, 2000

Unit capacity:

- Iron Ore - 4 to 150 TPH

- White Minerals -2 to 100 TPH

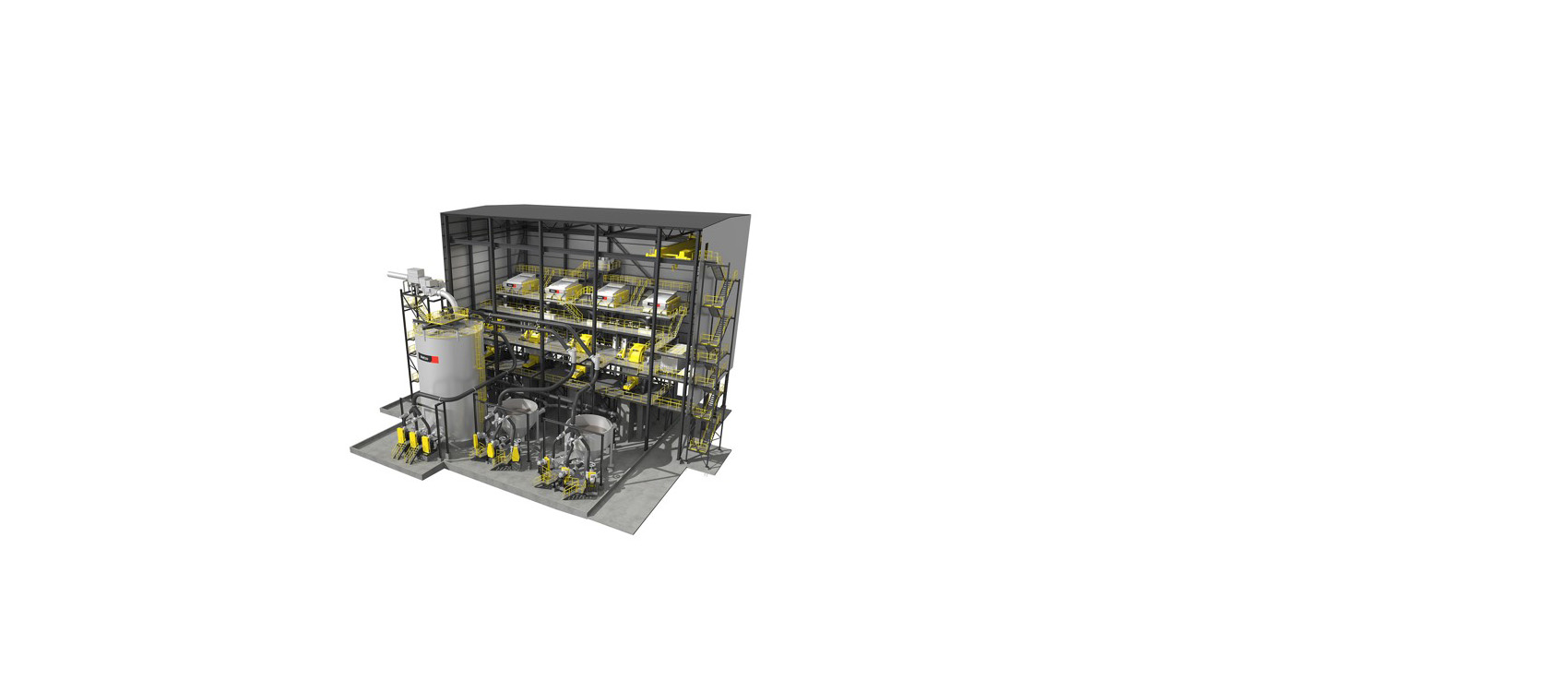

Description: Pre-engineered building modules

SLon® sizes: 2500, 3000, 3500, 4000

Unit capacity:

- Iron Ore - 70 to 2000+ TPH

- White Minerals - 50 to 1500 TPH