See how other companies have improved profitability and reduced risk!

Metso HGMS high gradient magnetic separators are designed to recover weakly magnetic material from non-magnetic matter and can be used for many applications including the processing of iron ores, rare earths and other weakly magnetic minerals, which are not normally treatable by ordinary magnetic separators.

Solving your separation problems

Metso HGMS separators are designed around a unique magnetic system with high capacity matrix material which together produces the required high magnetic field gradient to enable the capture of weakly magnetic minerals.

High capacity

Due to the unique magnetic system, very large unit capacities can be provided. The HGMS separators are available in several sizes and magnetic ratings to suit each individual application.

Ease of operation

Designed to allow certain variations in feed conditions without need of manual adjustments.

Low maintenance costs

The wear of other non-lined components like the matrix material, is extremely low due to the controlled pulp flow pattern.

Applications

As a lot of minerals are magnetic to some degree and others are associated with minerals that are ferromagnetic or paramagnetic, high gradient magnetic separation can often be used in separation where normally difficulties are experienced with other processes.

The paramagnetic minerals at the higher end of the list are normally easy to recover. Many low susceptibility minerals are associated with other minerals or have traces of Fe in the crystals, and are hence often possible to separate.

- Hematite recovery

- Pyrrhotite extraction

- Chromite fines recovery and / or upgrading

- Ilmenite fines recovery

- Wollastonite upgrading

- Kyanite recovery

- Apatite upgrading

- Sulphide ore recovery and separation

Technical description

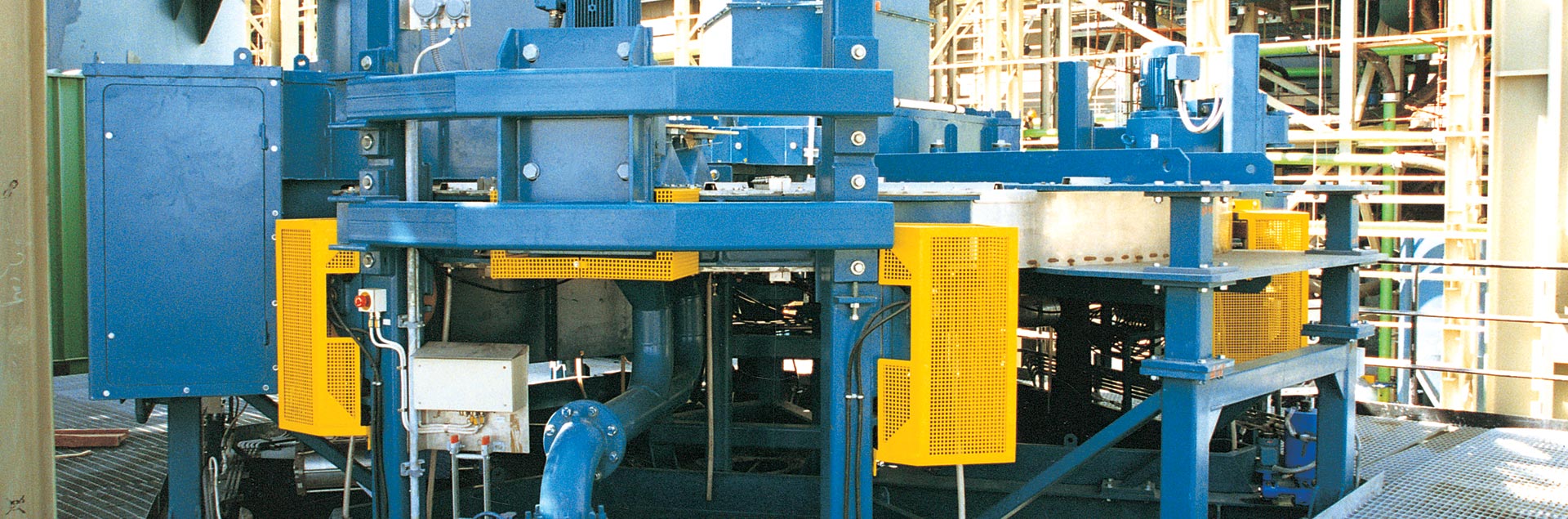

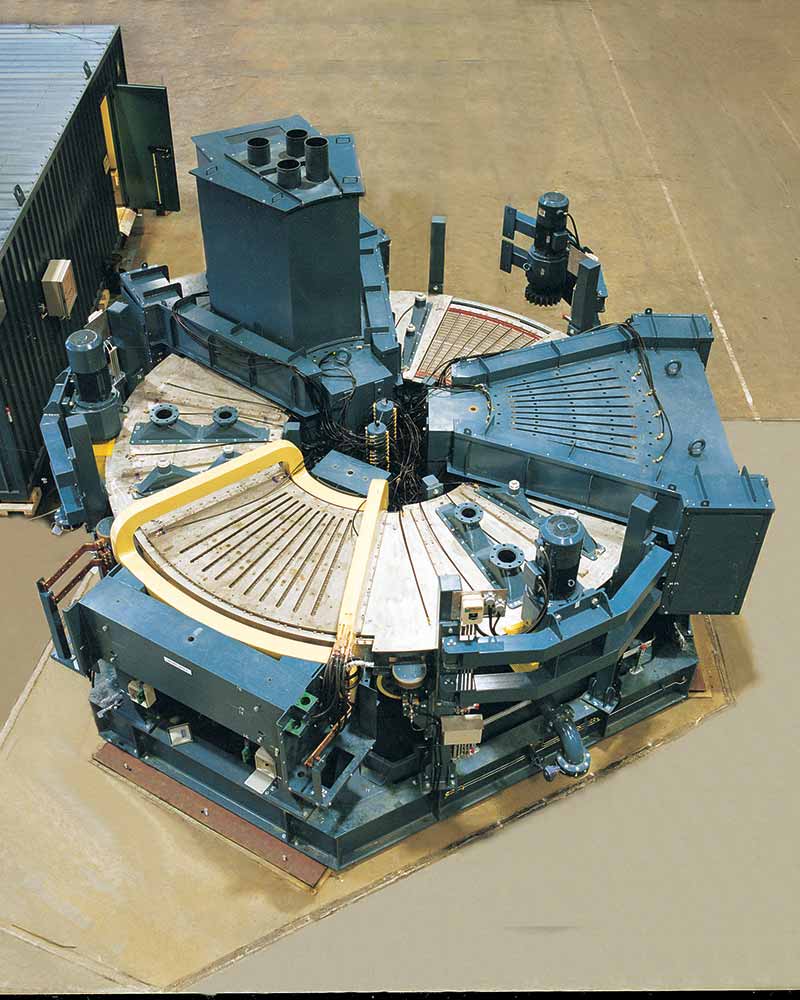

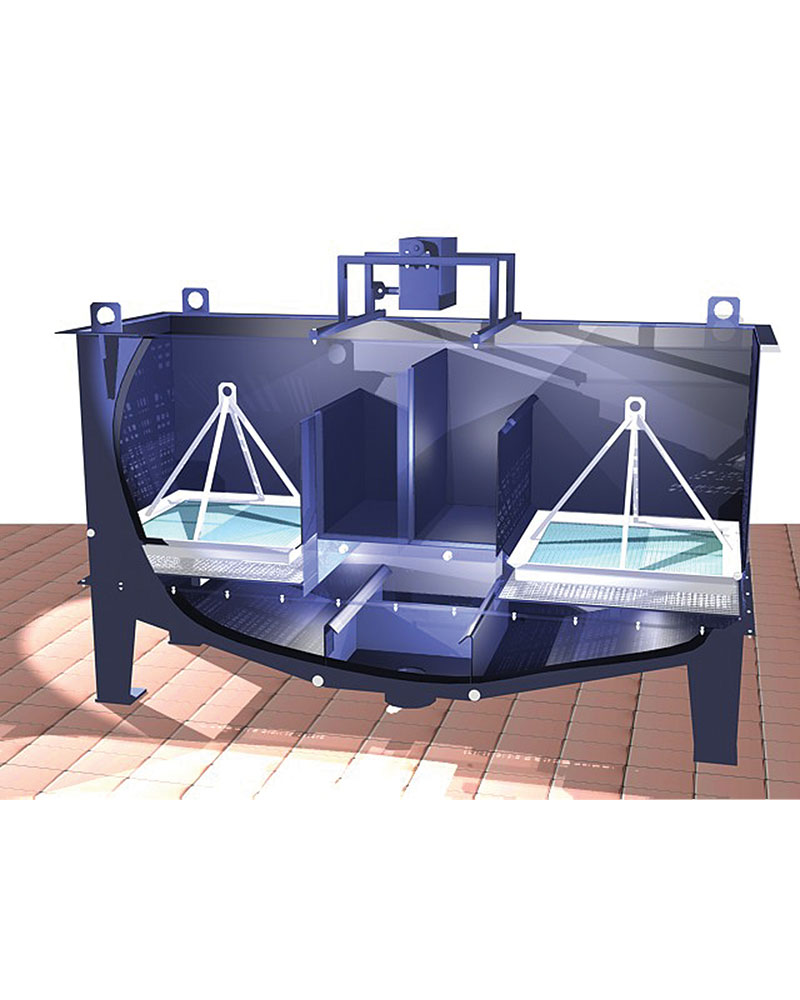

The main unit consists of a heavy frame, one to three magnetic heads, and a matrix ring with matrix cassettes.

The magnet head(s) are open on two sides to allow the matrix ring to travel continuously through the same during operation. On top of each magnet head are feed and rinse water boxes mounted for feeding and rinsing the matrix by gravity through slots in the magnetic return steel.

The magnetic product is flushed away from the matrix at the flush station by means of low-pressure water and vacuum. Steel plates at top and bottom enclose the entire matrix ring.

The matrix ring is divided into a number of compartments and each compartment is isolated by rubber lip seals on all sides on top and on bottom.

Contact our experts to learn more!

Your information is safe. Check our privacy notice for more details.

Thank you!

We will shortly contact you. You can send a new inquiry again after 15 minutes.