Safer and faster wear readings.

Thorough and detailed insights and accurate maintenance planning

Long-lasting liners optimized for your current conditions reduce CO2 emissions.

Reduced cost of operation with quick and easy maintenance

- Improves safety

- Minimizes inspection shutdown times

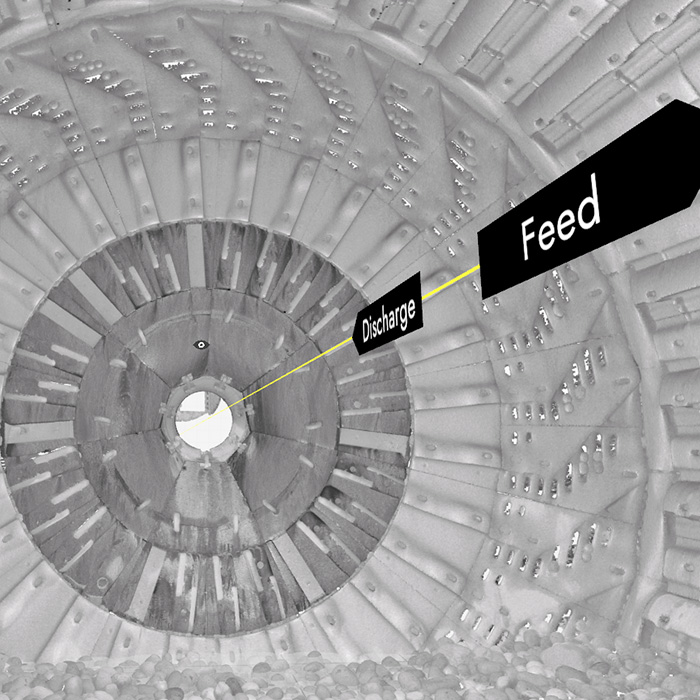

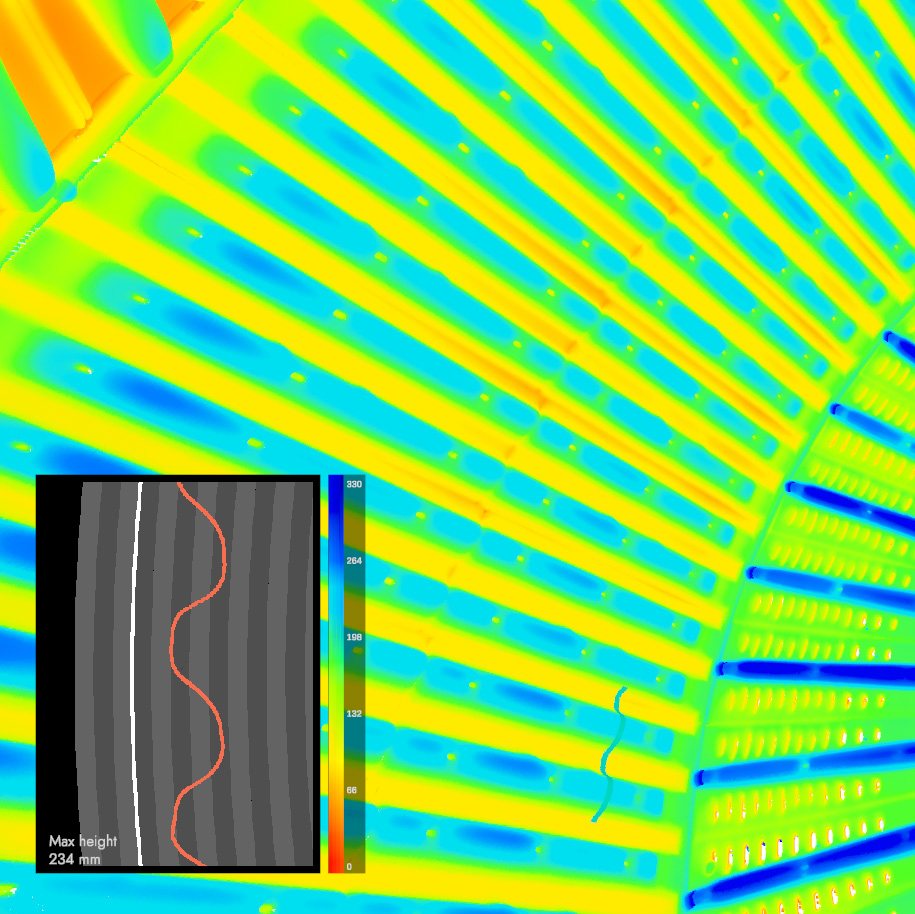

- Captures wear data on the entire mill

- Offers reliable reline forecasting

- Optimizes liner designs

- Improves identification of liner abnormalities to significantly reduce unforeseen liner failures

- Long-lasting liners optimized for your current conditions reduce CO2 emissions.

Metso MillMapper™ is the patented industry standard in mill liner condition monitoring. MillMapper™ liner wear monitoring allows your maintenance and operational personnel to improve the performance of your mill.

- Understanding how your linings wear has a direct impact on the performance of your grinding mill.

- Metso’s wear management solutions harmonizes liner life cycles, optimize throughput and uptime and empower better decision making with accurate wear reports and thorough analysis and wear forecasts.

- Knowing the current and historical wear rates, wear behavior, and performance of the mill is a prerequisite for liner optimization.