- Supports the decarbonization of the mineral wool production process

- Based on proven, state-of-the-art proprietary equipment

- Equipment design enables high plant availability and long furnace campaign life

- Designed for safe furnace operation

- Can be integrated into existing production lines

- Modular design that is easy to tailor for individual applications

- Modular design enables conversion of existing production lines to fossil-free operation

- Key technologies based on numerous proven commercial references in various ferroalloy and non-ferrous applications

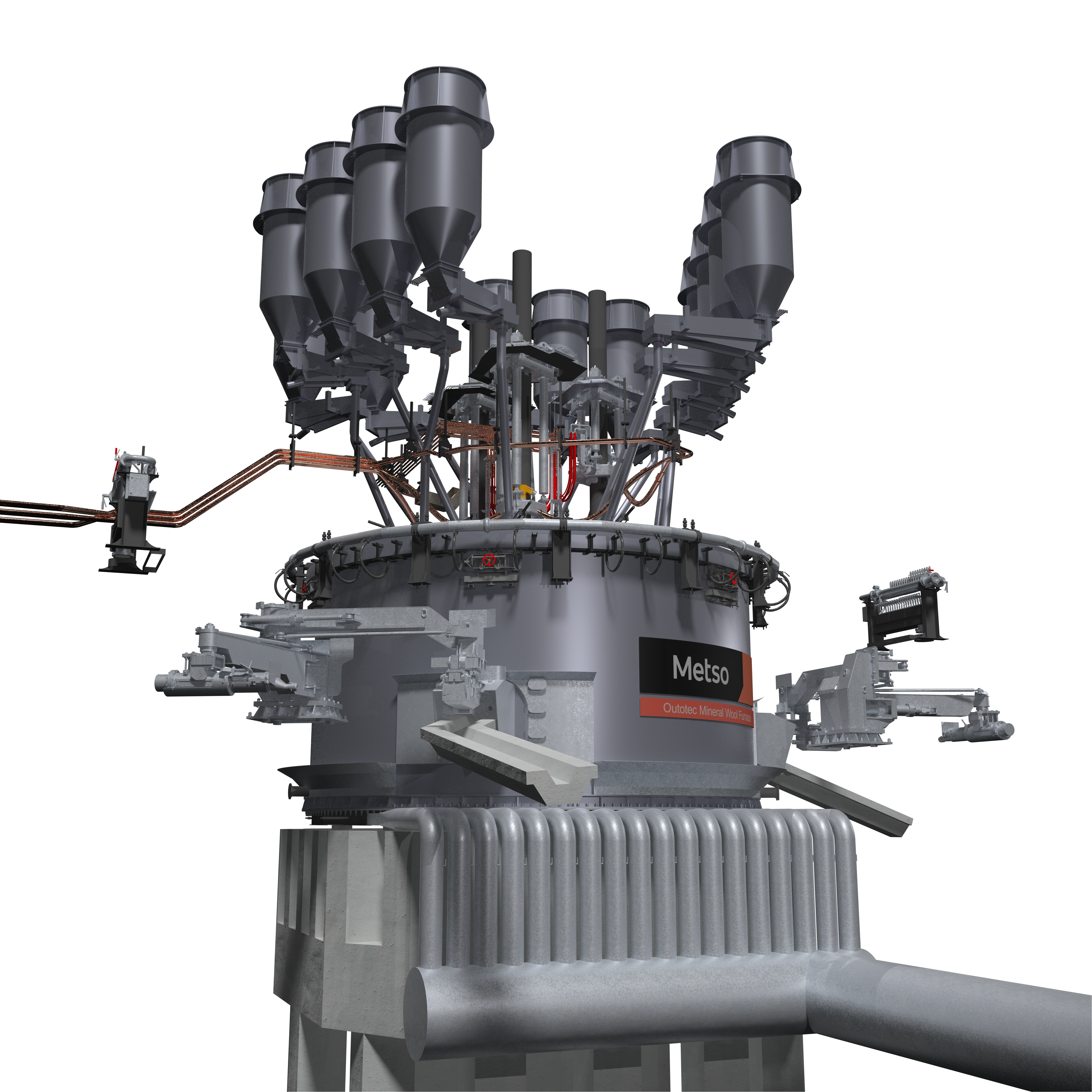

- Water-cooled roof and shell

- Electrode equipment

- Furnace refractories

- Electrode sealing

- Sentinel cooling headers

- Process automation

- Digital tools such as process advisor and digital twin to optimize operation

- Plant solution can be complemented with gas cleaning system and other proprietary technology