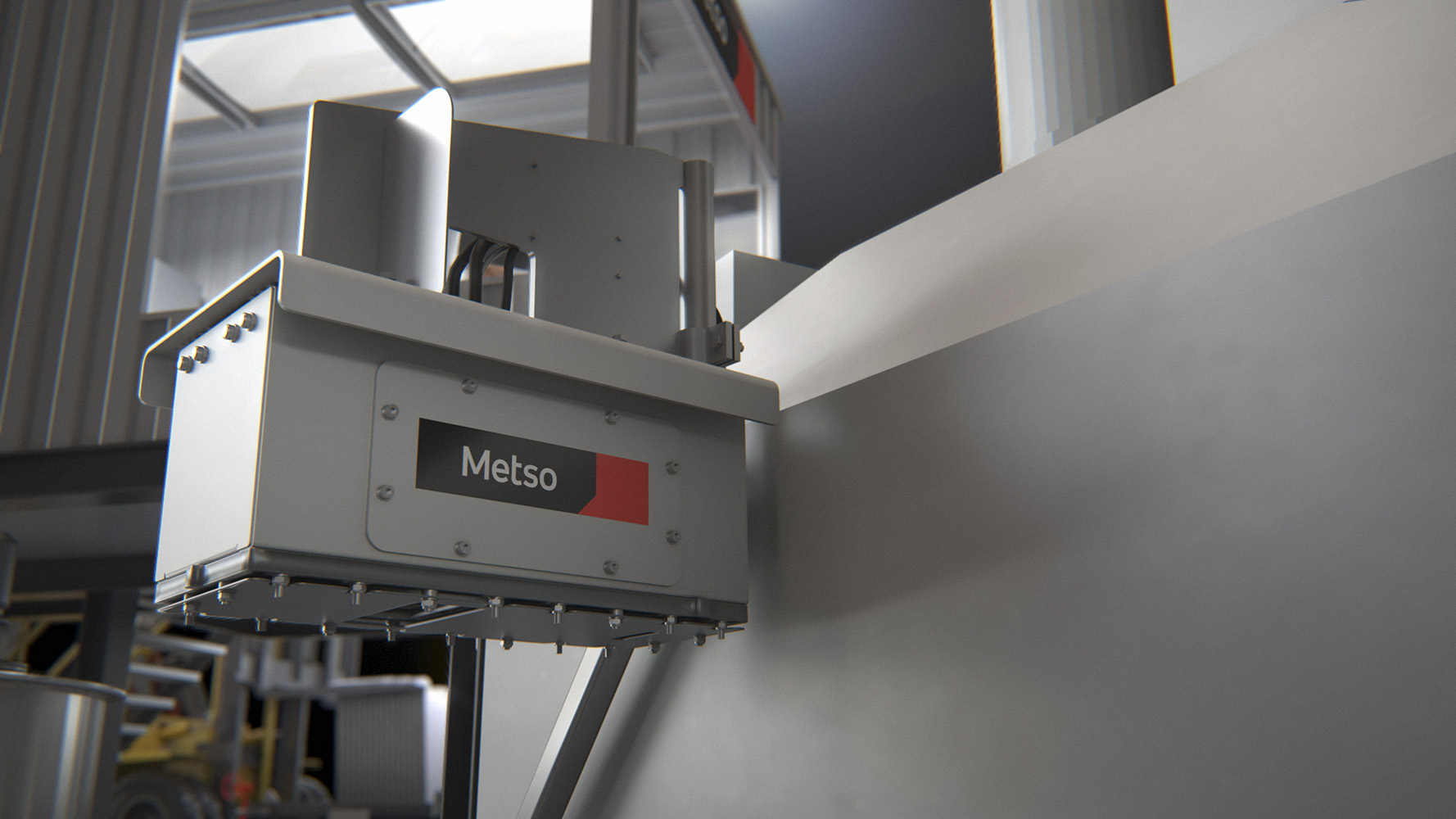

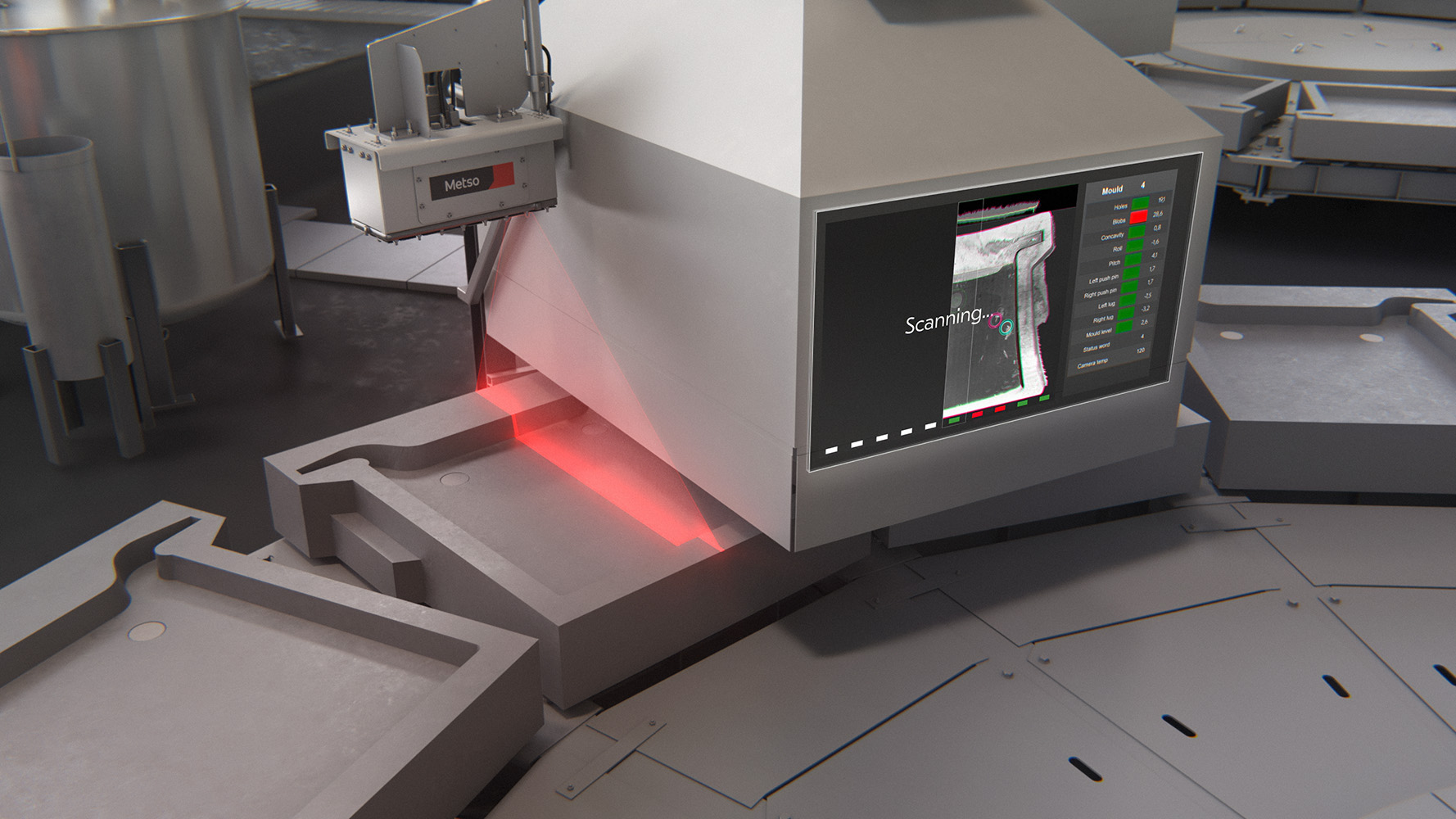

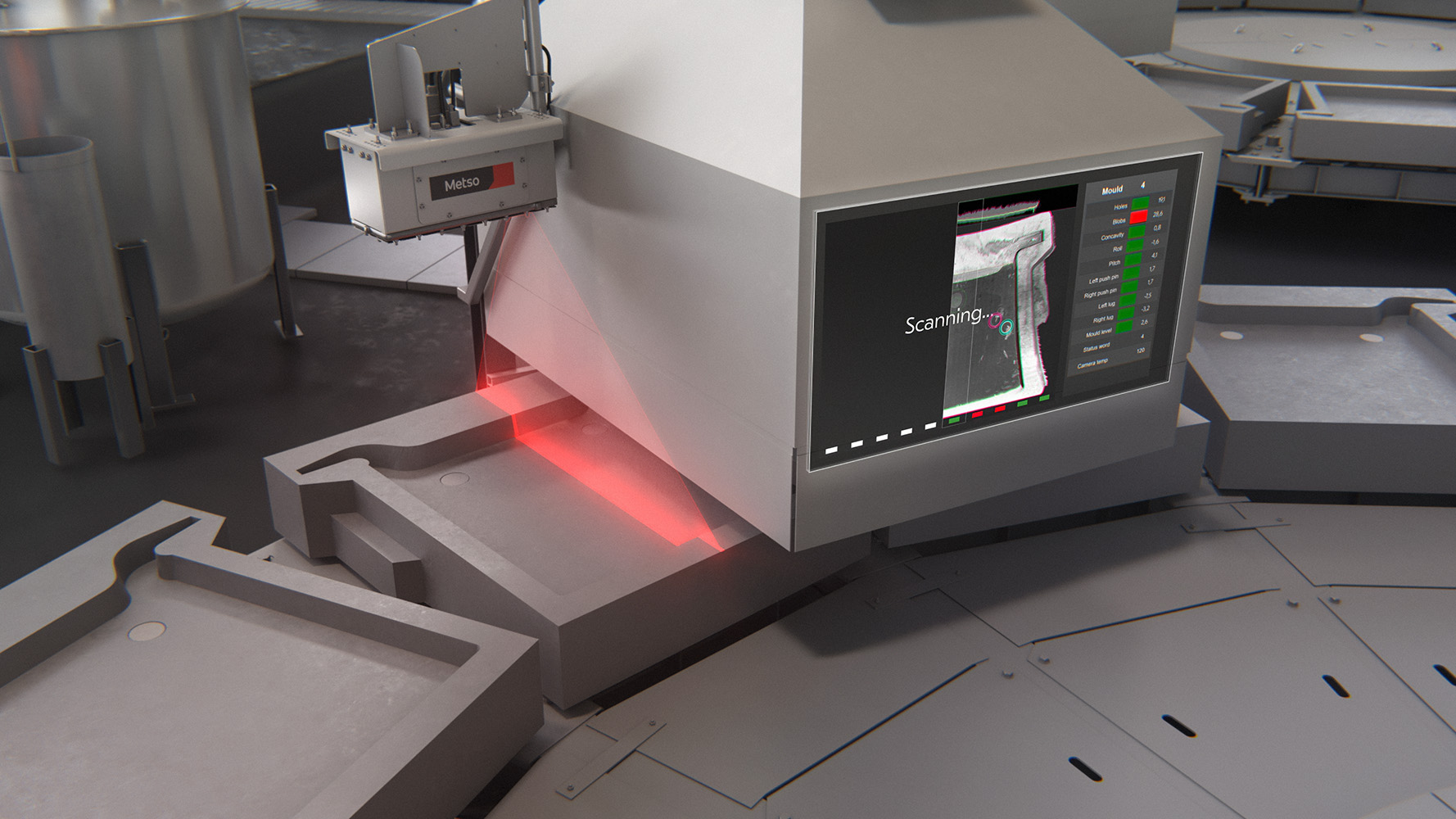

- Uses machine vision technology to enable preventive maintenance for copper moulds in anode casting shop.

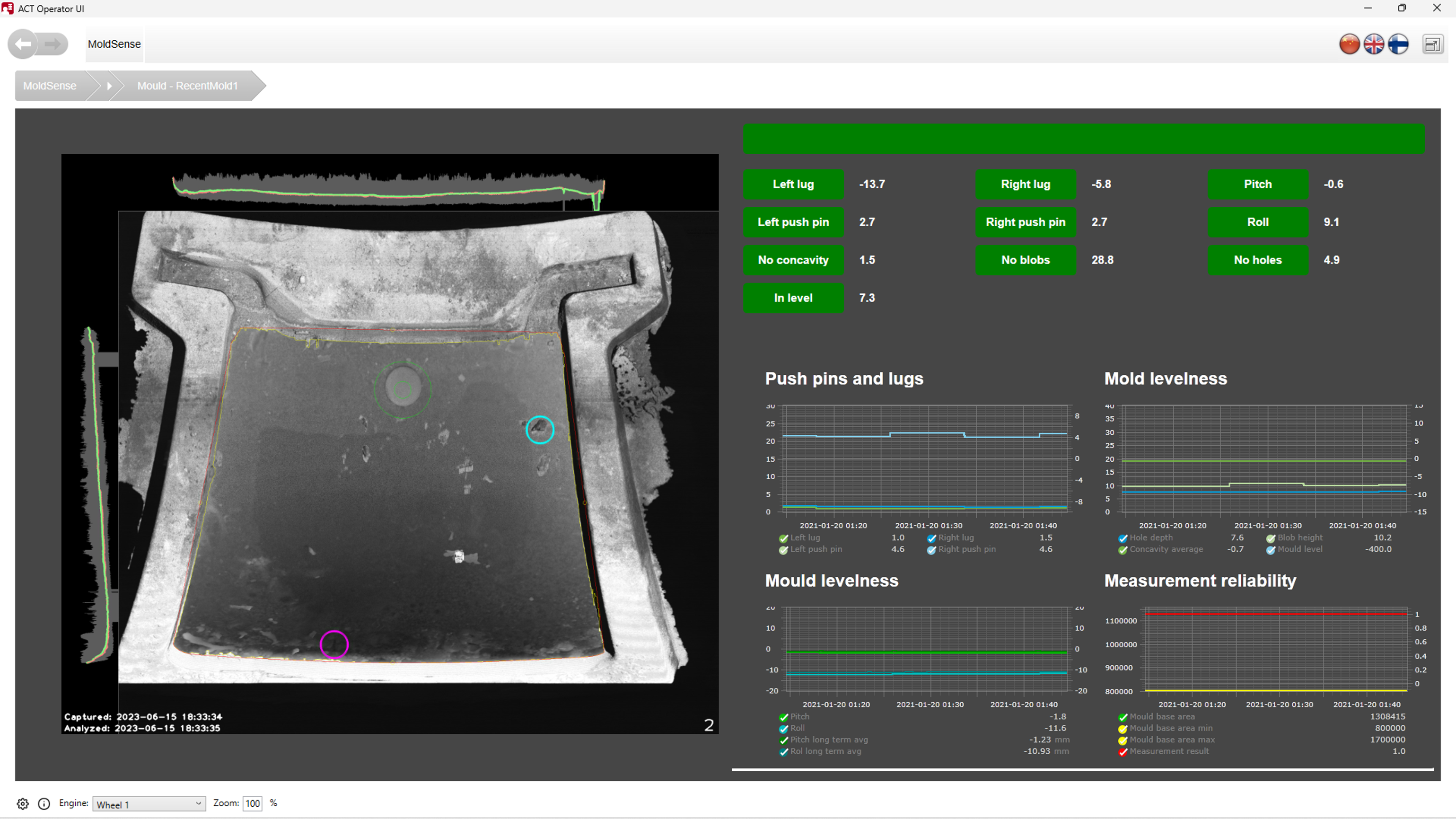

- Helps to ensure that the moulds are level and measures their defects and distortion.

- Monitors any changes in the condition of the moulds during casting.

- Gives alams for push-pin height deviation, broken lugs and defects in the mould pit area.