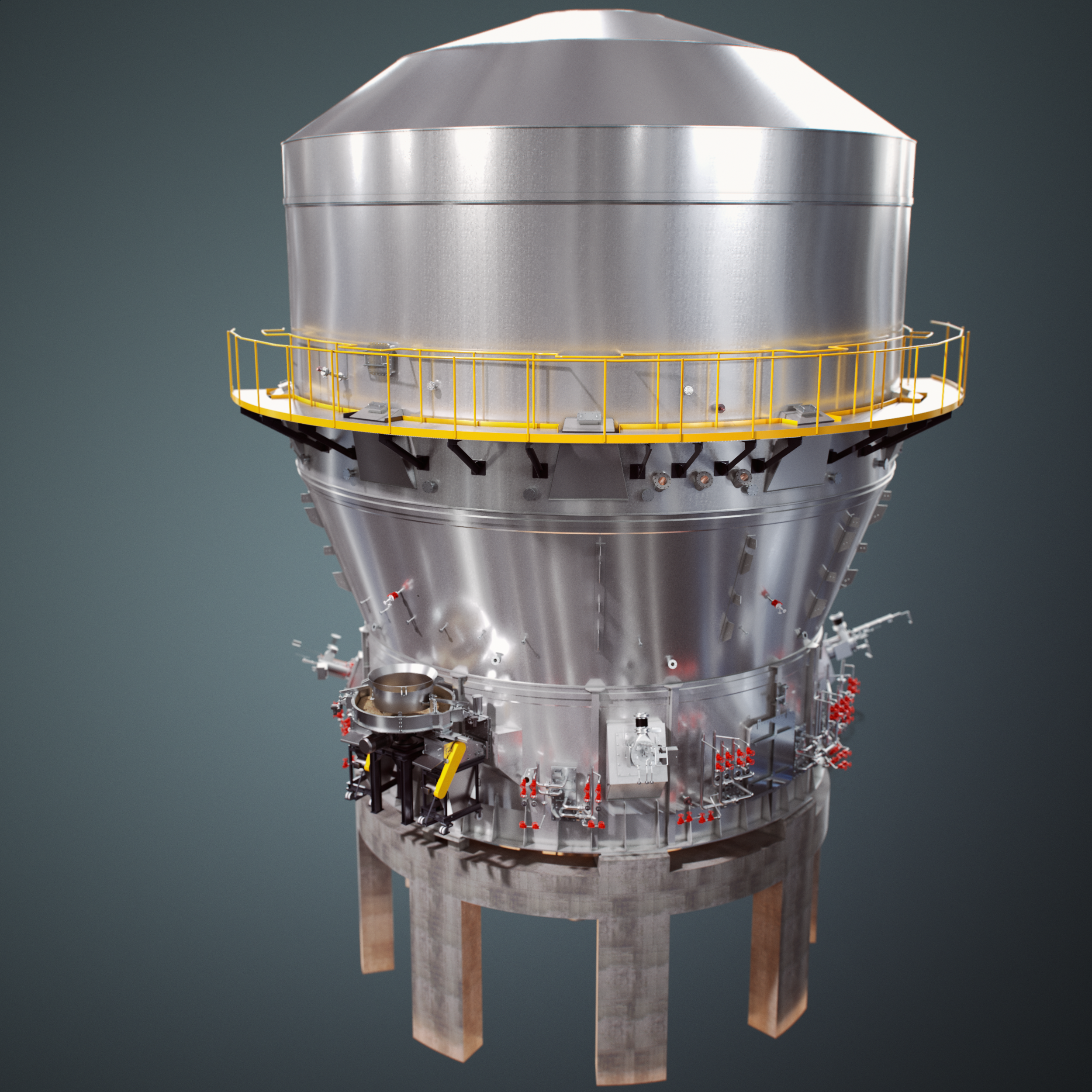

Metso's Next Generation Fluid Bed Roaster is a reactor with improved individual components to enable more efficient and stable roasting plant performance, including:

- Dual feedstock: feed pretreatment system (FPS) & conventional feed system

- Roaster feed system: roaster table feeder (RTF), slinger belt feeder (SBF) & feed gate valve (FGV)

- Cooling coils

- Underflow discharge device

- Freeboard cooling

- Digitalization: roaster optimizer & oven monitoring

- Improved safety: reduced personnel at workface

- High feed rates, efficient heat recovery, and other improved process parameters

- Improved plant availability in the roasting area and hence availability of downstream plant sections

- Process control enhancement

- Reduced operating costs

- Enables operation with finer materials and also residuals

- Adaptation of feed system depending on feed material characteristics

- Significantly reduced spillage at roaster feeding system

- Improved gas tight production

- Minimized operational interruptions

- Improved operations via a merger of digital solutions, focused measurement and equipment development

- Extended equipment lifetime