Watch our NextGen Webinar: Unleash the Future

Metso hosted a free webinar on the topic on 12 October, 2022, at 9:00 a.m. and 16:00 p.m.

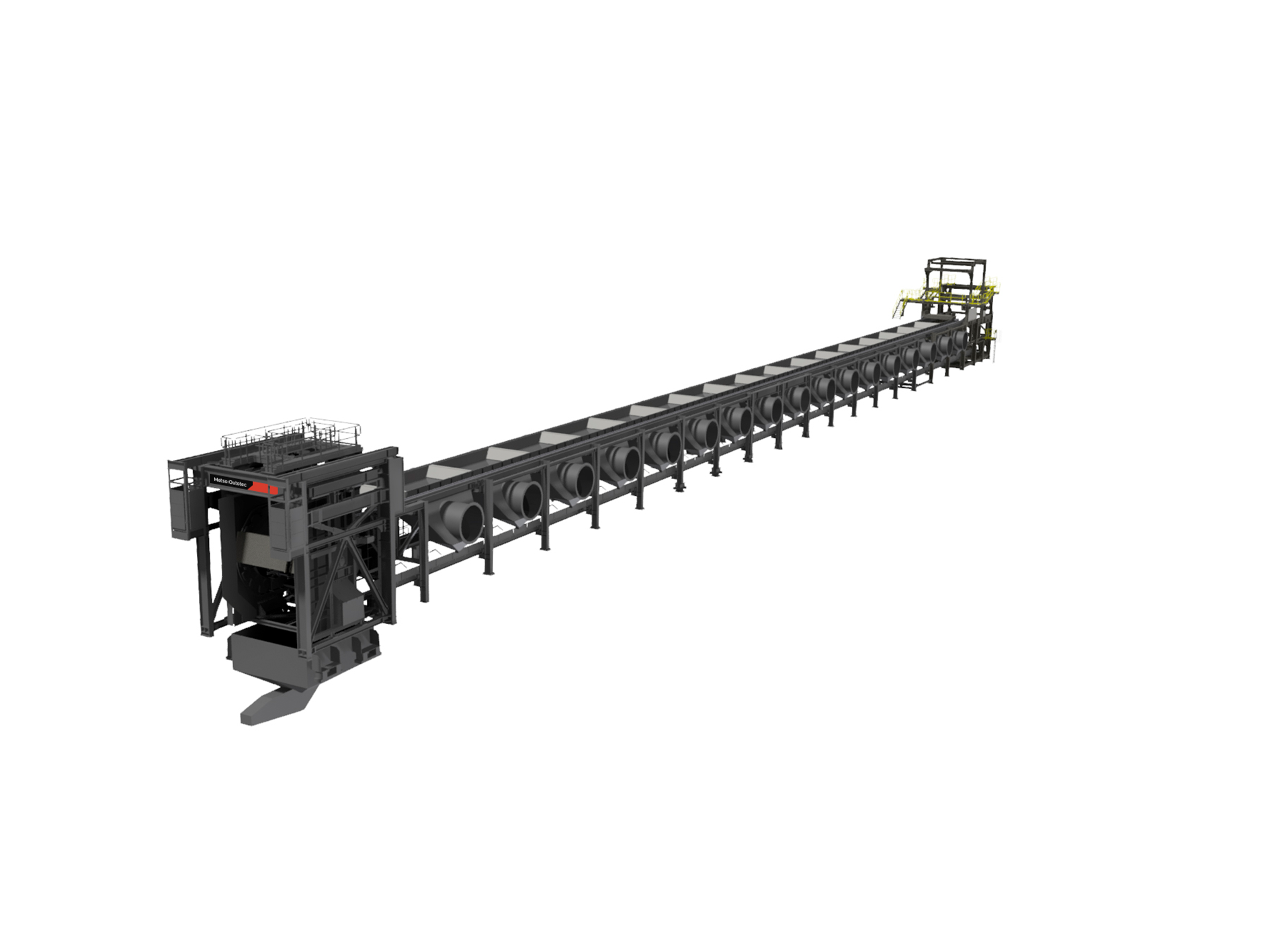

The traveling grate indurating process is responsible for two-thirds of the world’s installed pelletizing capacity.

Metso offers the industry’s leading induration technology for iron ore pellet processing, which is based

on over 60 years of experience and world-class R&D.

This process produces pellets with excellent physical and metallurgical properties for a wide range of plant capacities up to >9 Mtpa. It ensures high performance and quality, low investment and operating costs, as well as reduced energy consumption and emissions. Since 1961, Metso has delivered more than 75 plants all over the world for a wide range of ore types. This is a testament to our market leadership and proven expertise throughout the years.

Carbon-neutral steelmaking and reduced greenhouse gas emissions are at the forefront of conversation in the steel industry today. Evidently, the transition to carbon-neutral steelmaking cannot be achieved without pelletizing with the availability of DR-grade iron ore pellets playing a crucial role.

While productivity, energy efficiency and emission levels of the plants have been significantly improved during the past 60 decades, the global challenge of climate change requires more drastic modernizations in design and operations in order to reduce the carbon footprint of these plants. Because of this, we have evolved our existing processes and developed the next generation of pelletizing plants to become carbon neutral and fully autonomous.

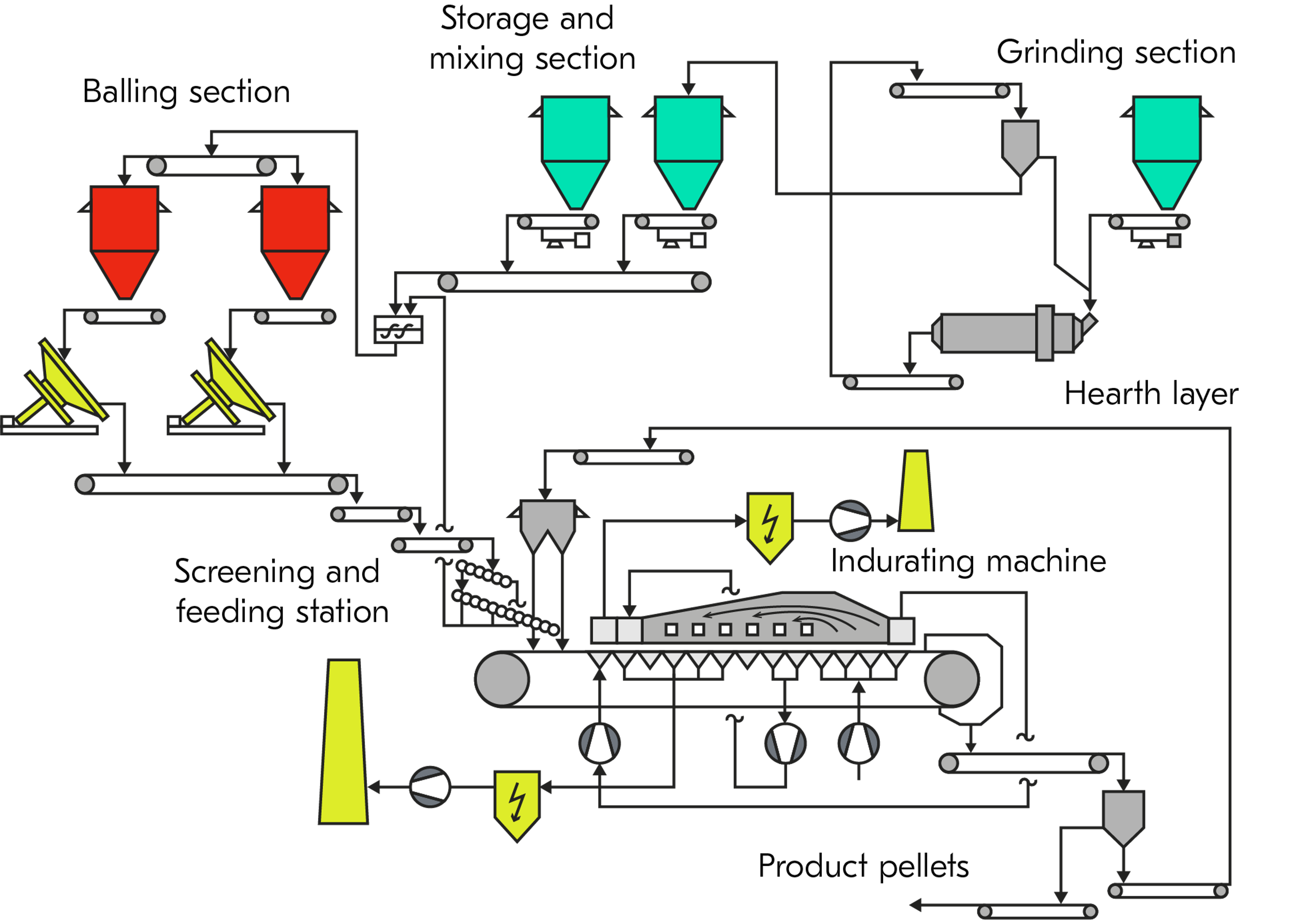

Metso proprietary equipment is always included for the main process areas.

It relies on the decades of process engineering experience and high degree of modularization:

The increasing quality of DR-grade pellets require more stable operations in a narrower operating window and thus, higher level process control where the need for human intervention is minimized. Here, advanced process control (APC) is of paramount importance. The already available Metso Optimus process advisor controls the processes in the induration furnace by means of pressure, temperature, and fan-speed control.

The final aim is to control the entire process based on online measurement of the quality (strength and metallurgical composition) of the burned pellets.

Learn more about our Digital Solutions for pellet plants here

Smaller capacity plants allow mining companies to expand their value chain and support decentralized steel-making concepts such as mini-mills. Metso Compact-sized Pellet Plant answers this need with a design based on a 3-meter wide indurating machine. It offers the same high performance and premium product quality as the larger size plants.

High level of standardization ensures optimized capital and operating costs, as well as the shortest production time. At the same time, the modular plant design allows flexibility for customization and future upgrades.