Over 12,000 jaw crusher installations since 1975

Read the story behind Nordberg® C Series™ jaw crushers

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

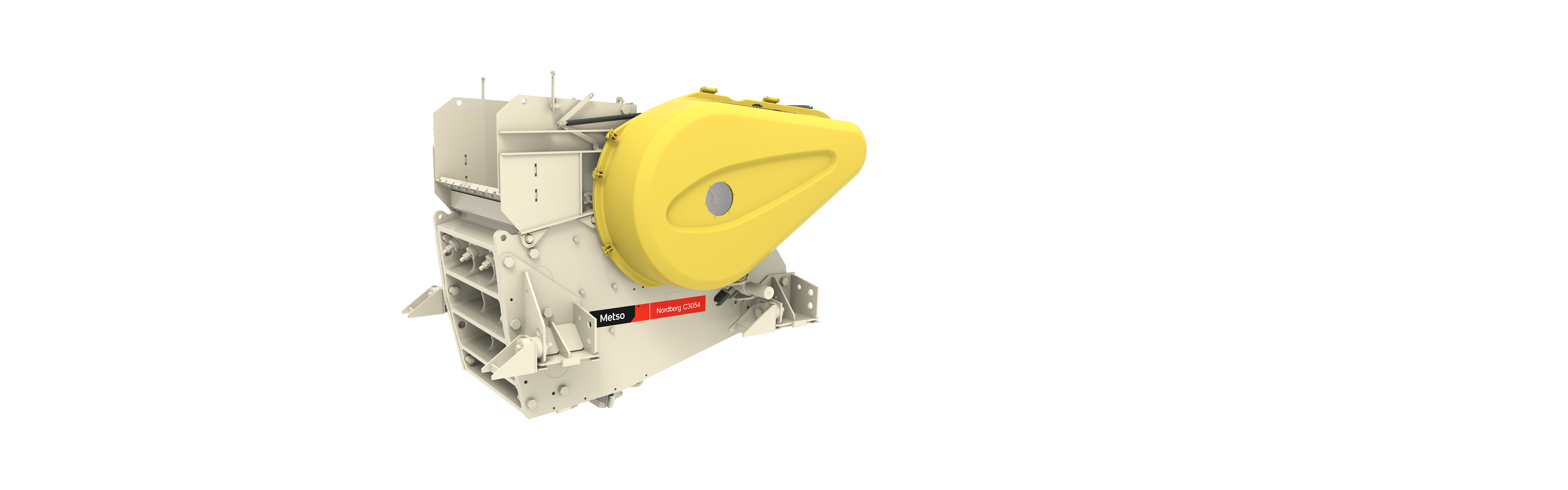

Nordberg® C3054™ jaw crusher is a wide cavity primary crusher engineered for maximum performance

and capacity. The wide cavity design allows the crusher to reach high volumetric throughput compared to

its size. Nordberg® C3054™ is the optimal choice when the maximum feed size is limited and large

quantity of material needs to be processed fast, like in recycling and gravel applications.

While having a different cavity design from other models, Nordberg® C3054™ has all the features you

can expect from a C Series™ crusher. Aggressive stroke and a steep cavity, combined with all the C

Series™ tools and safety equipment ensure a steady and efficient crushing operation.

Nordberg® C3054™ is designed for safe operating and easy maintenance. Lifting tools for items such as

jaw dies, cheek plates, and toggle plate are always delivered with the crusher to simplify maintenance,

making it safer for the crusher operators and service crew.

Nordberg® C3054™ jaw crusher is easy to install to stationary or mobile platforms with the included

support assembly, which has dampers to absorb vibrations and doesn’t require bolts between the crusher

and the supporting structure. The pinned and bolted frame structure and bolt-on options are easy to

dismantle if the crusher needs to be transported in tight spaces.

| Crushing unit | Nordberg® C3054™ |

| Feed opening | 1380 x 760 mm (30” x 54”) |

| Installed power | 160 kW (200 HP) |

| Speed | 260 rpm |

| Max. capacity, scalped feed | 670 mtph / 740 stph |

| Max. capacity, non-scalped feed | 1030 mtph / 1125 stph |

| Weight (basic unit) | 26 500 kg / 58 420 lbs |

Uncompromised reliability: Proven C Series pinned and bolted frame design without welding. Premium-quality components

High material intake: Wide cavity design allow high volumetric intake. Aggressive C Series kinematics ensure efficient production.

Easy to install, operate and maintain: Remote monitoring and IC-automation for reliable operation. Possibility to transport in pieces. Service tools as standard.

Wide range of options: C Series optional equipment offering to meet all customer needs, including flywheel safety guards and drive system for both sides.