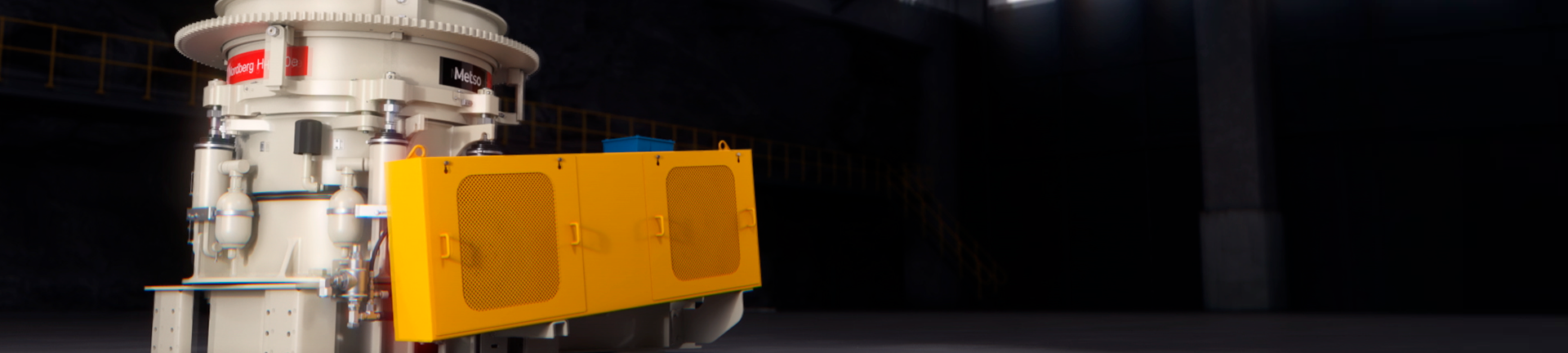

Case study: Positive impact with the new HP200e™

The new Nordberg® HP200e™ cone crusher provides better performance and uptime in a more sustainable way. It offers enhanced performance, easier and safer maintenance, and a series of other improvements, making it the perfect choice for aggregate and mining operations

Check the video

- New enhanced kinematics and more efficient chambers

- Up to +15-20% performance in Secondary application (compared to HP200)

- Up to +10-15% performance in Tertiary application (compared to HP200)

- +10% more head motion

- +20% more power (in kW)

- +20% more force

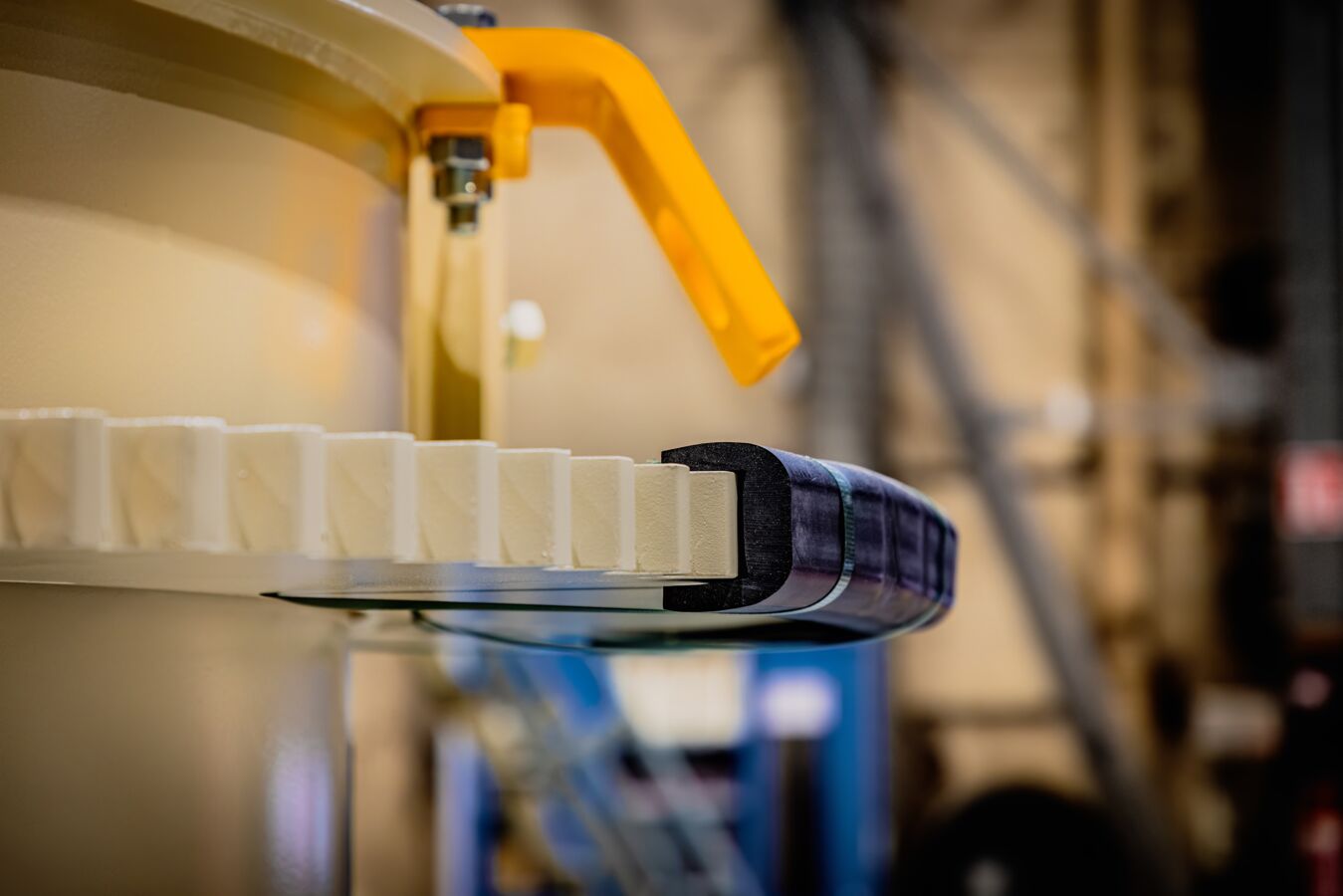

- No-backing liners for quick, easier and safer liner change.

- Head anti-spin brake extends liner wear life.

- Enhanced tramp release cylinder mounting.

- New feed cone lifting tool, for safe lifting and handling.

- Three alternative kinematics to choose from.

- Alternative speeds.

- Enhanced chamber designs and application specific chambers.

- Exceptionally wide chamber offering

Enhanced performance

Evolution in performance is achieved by four factors: kinematics, chambers, release force and power rating. New HP200e crusher’s performance is up to +15-20% (compared to traditional HP200 crusher) when used in secondary application and up to +10-15% when used in tertiary application.

Tune the HP200e crusher into the wanted application by choosing the optimal kinematics. There are three alternative kinematics to choose from.

- Enhanced kinematics for maximum performance in terms of capacity and reduction.

- Conventional kinematics for conventional HP200 performance. This is to reach the same performance level as before with the HP200 crusher. To be used when facing limitations in the circuit or when available power is limited.

- Reduced stroke for reduced throughput. To be used when further limiting throughput for rest of the circuit, when tuning the crusher into a specific application, or when limiting power and force.

Improved uptime and serviceability

HP200e cone crushers are fitted originally with no-backing manganese (mantle and bowl liner). This saves time in liner replacement as no time is needed for backing compound solidification.

Logistics is easier as there is no need to source, store and transport backing compound.

Liner installation process becomes much safer as there is no need to handle, mix and pour the backing material. Solution is environmentally friendly as backing material is not needed.

Specific feed cone lifting tool provides further safety improvement, it is designed specifically for safe lifting and handling of the feed cone. Split nut and easy-to-remove pin connection make tramp release cylinder easier to service. No need to use (hazardous) Locktite glue in nut locking and no need to give heat in nut removal which is safety benefit

Extended liner lifetime thanks to the head anti spin brake, which slows down head spin on idle. Optional ring bounce monitoring enhances machine protection.

Great parts compatibility between crusher generations

Majority of the spare and wear parts of the new HP200e and the HP200 cone crusher are compatible enabling economical, operational and environmental benefits for mixed fleet operations. With the bowl and head upgrade kit, the new no-backing liners can be installed in the HP200 cone crusher. Existing liners with backing material can be used in the HP200e, too.

Wider application coverage

New application specific chambers:

- Coarse chambers for secondary crushing

- Fine end chambers for tertiary and fine crushing

- EC (Extra Coarse) chamber introduced as a new chamber option in this size class Further developed C (Coarse) chamber

- F-NF (Narrow Fraction) to maximize yield of typical aggregates fractions (for example 5-8mm (imperial dims), 8-11 mm)

- F-Sand chamber for specific sand production

Technical specifications

Metric | Imperial | |

|---|---|---|

| Basic crusher weight * | 11,100 kg | 24,500 lbs |

| Complete crusher weight ** | 12,300 kg | 27,000 lbs |

| Maximum power | 160 kW | 200 HP |

| Head diameter | 940 mm | 37” |

| Stroke options | 62 mm / 77 mm / 85 mm | 2-7/16” / 3-1/32” / 3-3/8” |

| Number of chambers*** | 10 | 10 |

| Capacity up to | 290 mtph | 320 stph |

| * Bare crusher weight ** Crusher weight with options *** Additional offering: optional liners range for use with backing material. Different alloy alternatives. |

Spares, wears & services

Contact local sales experts

Select your industry to open the form.

Your information is safe. Check our privacy notice for more details.

Thank you!

We will shortly contact you. You can send a new inquiry again after 15 minutes.