How others have improved profitability and reduced risks?

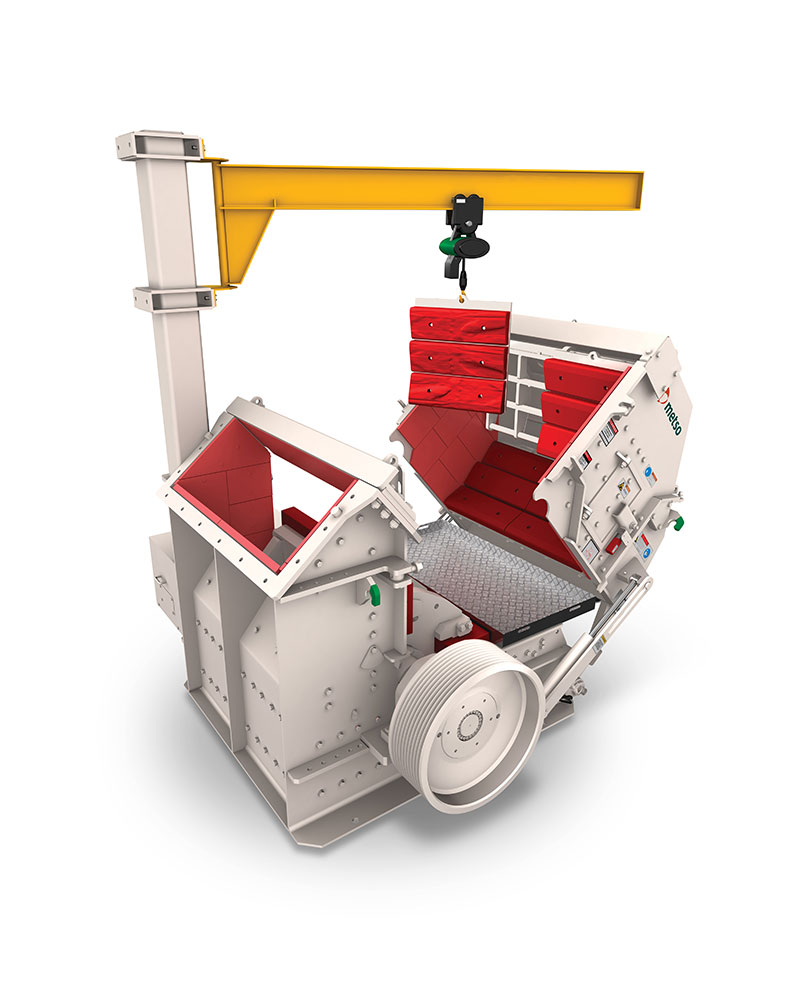

Nordberg® NP Series™ horizontal shaft impact (HSI) crushers are known for high reduction ratios when processing all type materials. They deliver unbeatable performance in primary, secondary and tertiary crushing in aggregates production, mining operations, as well as recycling applications.

High performance

High reduction ratio. Good quality end products.

Reduced plant operating costs

Durable wear parts and mechanical components.

Configured for your needs

Crusher settings can be customized for any requirements.

Easy maintenance

Faster service reduce downtime and increase production capacity.

High performance

Nordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design. This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs.

Nordberg® NP™ crushers have a unique blow bar attachment system. With an optimal blow bar alignment on the backing beam contact faces, the attachment system reduces risks of breakage and enables pushing the use of cast iron in blow bars beyond conventional limits.

At nominal speed, the high inertia rotor improves crushing reduction and provides stability in the process, reducing energy consumption and increasing long-term performance.

Reduced plant operating costs

Long experience in crushing, and continuous collaboration with customers and research laboratories have resulted in technical innovations that improve Nordberg® NP™ crushers’ reliability.

High capacity combined with high reduction ratio results in high performance crusher. In addition, whenever tertiary crushing stage can be avoided, the capital costs and need for energy drop notably.

Durable wear parts and mechanical components reduce maintenance costs. Mechanical reliability, simplified process and machine operation, as well as easy and safe maintenance increase the global availability of the plant and profitability.

Configured for your needs

Nordberg® NP crusher is an excellent choice especially if your output and productivity demands are stringent.

The crusher configuration can be adjusted for your requirements. Options like full hydraulic adjustment, third breaker plate, different grades of steel and cast iron for the active wear parts, enable customizing the crusher exactly for your needs.

Furthermore, Metso IC™ crusher automation can control the crusher operation and give a complete overview of the crushing performance. It also allows adjusting Nordberg® NP crusher from a distance.

Easy maintenance

Nordberg® NP Series™ crushers are designed to be mechanically resistant. Whenever maintenance is required, changing parts is made simple and easy.

Rotor Positioning System (RPS) is available for all the crusher sizes. This system, available as electric or manual version, has been developed to ensure operator safety during maintenance phase, and is already compliant with future standards EN1009.

It allows positioning the rotor during the maintenance period when changing the blow bars or adjusting the breaker plates without human intervention inside the crusher.

Nordberg NPe impact crushers provide significant improvements

Nordberg NP1110e, NP1213e, NP1315e & N1520e impact crushers provide significant improvements for your productivity, versatility, safety, and uptime. They have been proven machines operating in a diverse range of severe applications with excellent results in reliability and operating cost.

The NPe crusher delivers excellent particle shape across all product ranges, even with high reduction ratios. It can operate in both open and closed circuits and is widely used for producing coarse and fine aggregates from low-abrasion, soft rocks. Additionally, Metso's HSI technology performs exceptionally well in various applications, including recycled materials and medium to hard, abrasive rocks, offering strong performance and cost efficiency.

Nordberg® NP Series™ HSI crushers for primary crushing

Nordberg® NP Series™ HSI crushers for secondary and tertiary crushing

Parts and services

Check the video

Watch the video to see how we can help you to get the maximum potential out of your crusher to achieve improved crushing performance and lower cost per ton.

Chamber Optimization Program

Get the maximum potential out of your size reduction process to achieve improved crushing performance and lower cost per ton. By using our unique simulation software, our Chamber Optimization experts can design an optimized crushing chamber that matches the exact conditions under which you operate.

Downloads

Application guide: Nordberg® NP Series™ impact crusher wear parts

Language

English

Size

2.73 MB

Brochure - Nordberg NP Series Horizontal Shaft Impact (HSI) Crushers

Language

English

Size

1.66 MB

Contact local sales experts

Select your industry to open the form.

Your information is safe. Check our privacy notice for more details.

Thank you!

We will shortly contact you. You can send a new inquiry again after 15 minutes.