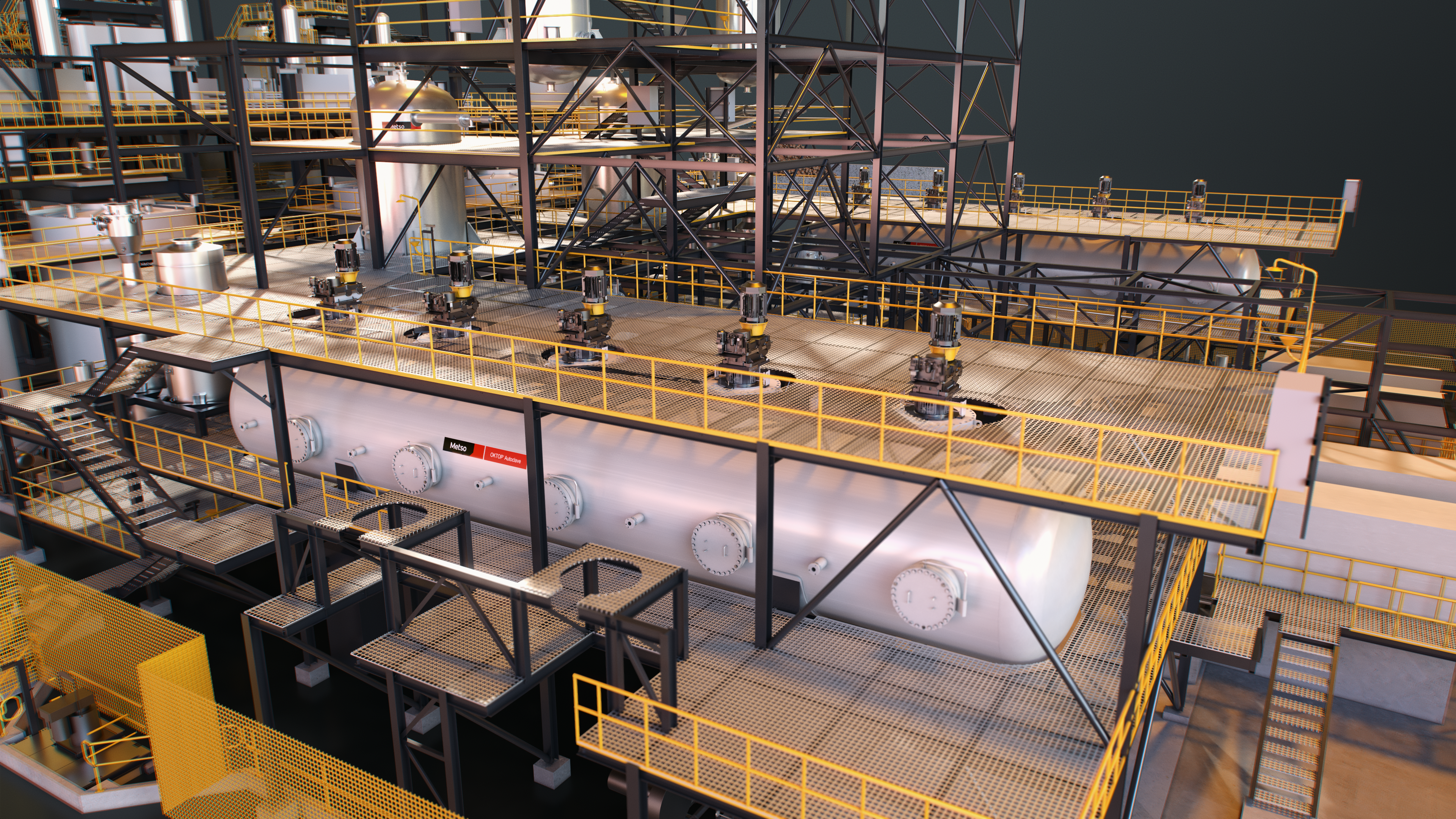

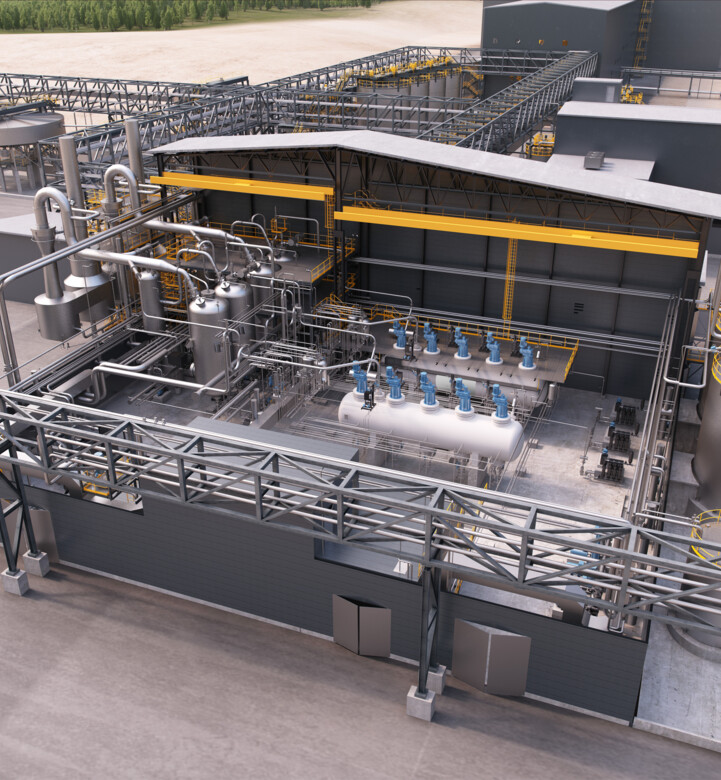

The Metso OKTOP Atmospheric Reactor is a mixing tank used in the hydrometallurgical process. The pressure inside the tank is at an atmospheric level, usually at a slightly negative pressure.

The reactor consist of two units:

Solids suspension and gas dispersion

The slurry inside the tank often contains solids in varying concentrations. These solids have to be suspended within the solution inside the tank. In some processes, gas is injected into the reactor. The gas agitator disperses it into smaller bubbles to allow efficient use. Metso has carried out a wide array of investigations for both agitational duties and can offer proven, reliable equipment. For example, the OKTOP 2000 series agitators have been specifically designed to operate in conditions with high solids content and gas dispersion rates.

Sustainable agitation

The mixing energy is selected based on the application, for example, low energy hydrofoil impellers for solid suspension ensuring low energy consumption. The use of a VFD in order to optimize operation is recommended. This can be further increased in solid suspension operation by utilizing Metso OKTOP SandSense and CloudSense.

Metso's OKTOP dispersion agitators provide high gas utilization in dispersion, even in situations where high solids are present in the solution. This means less power is used in gas compression and feeding the tanks. Also, less equipment is needed for the gas feed.

Typically, materials used in the reactor allow for a high recycling percentage at the end of the life cycle.

Novel features to enhance operation

In addition to the tank and agitator we can offer functionality enhancing components to the reactor such as heating and cooling baffles, gas distributors and novel features such as the formed bottom to reduce mixing energy in solids suspension and SandSense to control the agitation speed dynamically to produce just the right amount of energy needed for the mixing task in any given time

Good example is a CIL reactor used in cyanide leaching process, Metso can provide all equipment for the reactor enhanced with our proprietary instrumentation to monitor carbon behavior and solids suspension inside the reactor.

Accessories for the reactors

The reactors can be equipped with accessories to improve agitation or to perform other tasks. The corrugated bottom is an innovative new patent-pending design of the tank bottom that reduces the required agitational power to keep solid particles suspended.

In cases where heating or cooling of the tank is required, we can offer heat exchange baffles. Heating may be carried out with either steam or a liquid solution. Cooling is most typically performed with water.